Floating Pellet Fish Feed Processing Line with Small Feed Production Line

ZHENGZHOU YUFENG HEAVY MACHINERY CO., LTD.- After-sales Service:Sales Servies Support

- Type:Pellet Mill

- Processing Object:Animal-Derived Feed

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:Without Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

Base Info

- Model NO.:DGP90-B

- Pellet Mill Type:Screw Granulator

- Bulking Machine Type:Sigle Screw Bulking Machine

- Expanding Method:Dry Expansion

- Condition:New

- Applicable Materials Shape:All

- Warranty:13 Months

- Color:Multi

- Usage:Fish Feed Pellet

- Floating Hour:More Than 12 Hours on Water

- Capacity:300-350 Kg,H

- Pellet Size:0.9-20mm

- Certification:CE, ISO

- Advantage:High Efficiency

- Automatic:Yes

- Transport Package:Wooden Case

- Specification:warranty: 1 year

- Trademark:YUFCHINA

- Origin:Henan China

- HS Code:84833800

- Production Capacity:30 Sets Per Month

Description

Basic Info.

Model NO. DGP90-B Pellet Mill Type Screw Granulator Bulking Machine Type Sigle Screw Bulking Machine Expanding Method Dry Expansion Condition New Applicable Materials Shape All Warranty 13 Months Color Multi Usage Fish Feed Pellet Floating Hour More Than 12 Hours on Water Capacity 300-350 Kg/H Pellet Size 0.9-20mm Certification CE, ISO Advantage High Efficiency Automatic Yes Transport Package Wooden Case Specification warranty: 1 year Trademark YUFCHINA Origin Henan China HS Code 84833800 Production Capacity 30 Sets Per MonthProduct Description

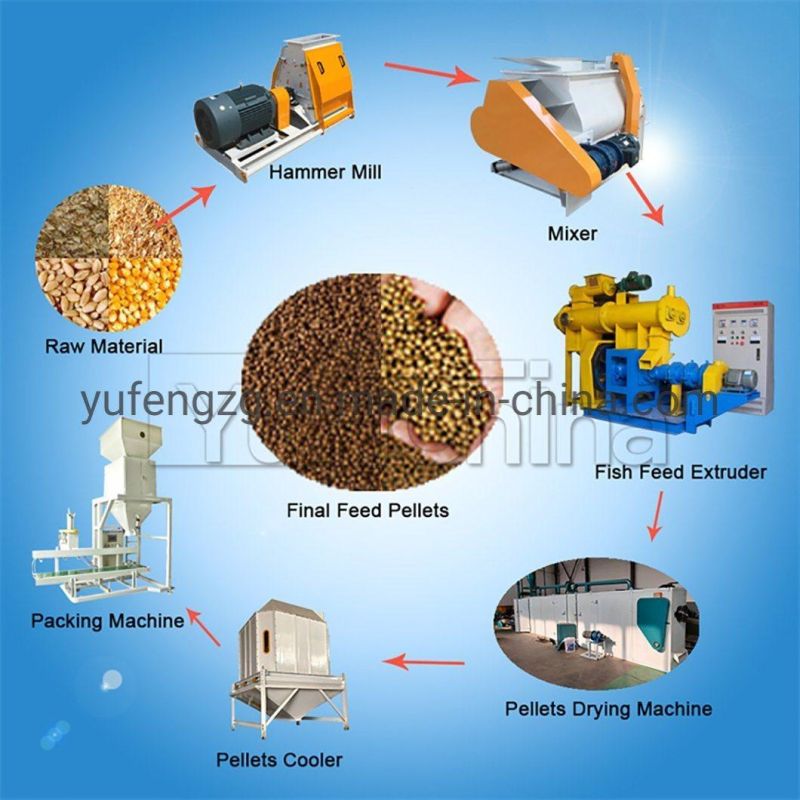

floating pellet Fish Feed Processing Line with Small Feed Production Line Description of Fish feed pellet mil

Description of Fish feed pellet milThe machine is widely used for producing grains into high-grade aquatic feed pellets for fish, catfish, shrimps, crab etc. The puffing pellets can float on water surface for over 12 hours,.According to your capacity and material ,We wil suggest you different model fish feed pellet machine.

Features of Fish feed machine

1. By adjustment of feed formulation and degree of expansion, the fish feed extruder can produce all kinds of floating, sinking, and slow sinking fish feed pellets.

2. Different molds can be chosen to make pellets with different diameters ( 0.9-15mm ) and shapes.

3. the fish feed extruder has the advantage of high efficiency and low power consumption.

4. Two types of pelletizing solution we can do, that is dry type and wet type.

Dry Type Pelletizing Solution:

No boiler needed in this process, even we need to dry the steam while pellet making. Raw material will be grain, soybean, etc.

Wet Type Pelletizing Solution:

Boiler Steam & conditioner are needed in this process, the steam will fully contact with the cereal and other raw materials.

5. Please be understand, whatever you choose dry type or wet type solutions, this fish feed making machine can make fish feed, shrimp feed, catfish feed, golden fish feed etc kinds of fishes and also pet foods.

Specifications of Fish feed mill

Specifications of Fish feed mill| Model | Capacity t/h | Motor power: kw | Feeding power: kw | Screw dia. mm | Cutting power:kw |

| DGP40-C (single phase) | 0.03-0.04 | 4.0 | 0.4 | Φ40 | 0.4 |

| DGP40-C (three phase) | 0.03-0.04 | 5.5 | 0.4 | Φ40 | 0.4 |

| DGP50-C | 0.06-0.08 | 11 | 0.4 | Φ50 | 0.4 |

| DGP60-C | 0.12-0.15 | 15 | 0.4 | φ60 | 0.4 |

| DGP70-B | 0.18-0.2 | 18.5 | 0.4 | φ70 | 0.4 |

| DGP80-B | 0.2-0.25 | 22 | 0.4 | φ80 | 0.6 |

| DGP90-B | 0.30-0.35 | 37 | 0.6 | φ90 | 0.8 |

| DGP120-B | 0.5-0.6 | 55 | 1.1 | φ120 | 2.2 |

| DGP135-B | 0.7-0.8 | 75 | 1.1 | φ133 | 2.2 |

| DGP160-B | 1-1.2 | 90 | 1.5 | φ155 | 3.0 |

| DGP200-B | 1.8-2.0 | 132 | 1.5 | φ195 | 3.0-4.0 |

More Pictures:

Welcome to know more about our fish feed processing machine.