1-1.2 T/H Fish Feed Extruder Machine/Fish Feed Making Plant

ZHENGZHOU YUFENG HEAVY MACHINERY CO., LTD.- After-sales Service:After Sales and Accessories Support

- Type:Pellet Mill

- Processing Object:Animal-Derived Feed

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:Without Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

Base Info

- Model NO.:DGP160-B

- Pellet Mill Type:Screw Granulator

- Bulking Machine Type:Sigle Screw Bulking Machine

- Expanding Method:Dry Expansion

- Condition:New

- Applicable Materials Shape:All

- Warranty:1 Year

- Color:Multi

- Usage:Feed Pellet Mill

- Pellet Size:0.9-15mm

- Certification:CE, ISO

- Advantage:High Efficiency

- Automatic:Yes

- Capacity:1-1.2 T,H

- Floating Hour:More Than 12 Hours on Water

- Motor Power:90kw

- Transport Package:Wooden Case

- Specification:warranty: 1 year

- Trademark:YUFCHINA

- Origin:Henan China

- HS Code:84833800

- Production Capacity:30 Sets Per Month

Description

Basic Info.

Model NO. DGP160-B Pellet Mill Type Screw Granulator Bulking Machine Type Sigle Screw Bulking Machine Expanding Method Dry Expansion Condition New Applicable Materials Shape All Warranty 1 Year Color Multi Usage Feed Pellet Mill Pellet Size 0.9-15mm Certification CE, ISO Advantage High Efficiency Automatic Yes Capacity 1-1.2 T/H Floating Hour More Than 12 Hours on Water Motor Power 90kw Transport Package Wooden Case Specification warranty: 1 year Trademark YUFCHINA Origin Henan China HS Code 84833800 Production Capacity 30 Sets Per MonthProduct Description

1-1.2 t/h fish feed extruder mahine/fish feed making plantGeneral Introduction to fish feed extruder mahine/fish feed making plant

To satisfy high demands for high quality fish feed pellets in world market, we customize the floating fish feed pellet plant by different capacity and automation requirement. It is used to produce variety materials into high-grade floating aquatic feed pellets for fish, catfish, shrimps, crab etc. With compact structure design and excellent performance, this floating fish feed pellet plant start from raw material intake to finished feed pellets bulk loading.

Features of Fish Feed Pellet Plant

A wide range of raw materials such as corn, wheat bran, paddy, soybean meal, paddy rice, sorghum, etc.

Besides floating fish feed pellets and sinking fish feed pellets, this production line can also produce high quality feed for pet, poultry and livestock, etc.

The diameter of the pellets can be from 0.9mm-15mm.

Capacity: We can also customize different fish feed pellet plants depending on your raw materials and specific requirements.

Why Choose fish feed making plant

This production line can produce floating fish feed, sinking fish feed, pet feed, livestock feed, etc.

2. features:

Smooth operation

Easy installation

Cost-effective

Long service life

Best-selling worldwide

The Benefits of Fish Feed Pellets

Easier to digest and absorb

Better fragrance and palatability

Reduce waste

Decrease disease

Convenient observation

Keep the water quality

The Process of the Complete Fish Feed Production Line

Crushing → Mixing → Extruding → Pellet Drying → Oil Spraying → Pellet Cooling → Pellet Packaging

Grinding-Feed Hammer Mill

To produce high quality fish feed pellets, fine grinding of raw materials is necessary. The finer the material is, the more surface area will be exposed, thus achieving the great gelatinization in conditioning. The feed hammer mill is adopted in this fish feed pellet line, which can benefit users by ideal crushing effect.

Mixing-Fish Feed Mixer

Efficient mixing is the the key step in fish feed pellet plant due to its direct influence on the feed pellet quality. Proper mixing will increase diet uniformity and improve the feedstuff quality. Our mixing machine stands out with high mixing uniformity, CV≤5%, and no segregation.

Extruding-Fish Feed Extruder

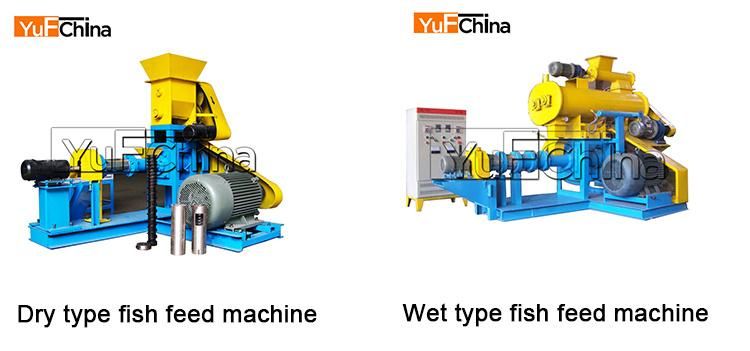

Extruding machine plays an important role in the whole plant. Floating fish feed extruder is widely used for producing variety materials into high-grade aquatic feed pellets for fish, catfish, shrimps, crab etc. The final pellets have the feature of unique shape and good taste, high nutrition and smooth textures. For feeds of fish and shrimp, the floating time in water can be adjusted by the extrusion degree adjustment. Feed pellets dia. is optional between 0.9mm and15mm. We have wet type fish feed extruder and dry type fish feed extruder for you to choice.

Drying-Fish Feed Pellet Dryer

Featured by high drying uniformity and low breaking ration, mesh belt dryer is preferred to reduce the high moisture content of feed pellets coming out from the extruder.

Oil Spraying-Oil Coating Machine

Our oil coating machine is used for spraying the oil, grease, vitamin, ect. to the feed pellets surface to increase the palatability of fish feed pellets. In the drum-type spraying machine, the additives can be contacted with pellet surface sufficiently and spray evenly. After spraying, the fish feed pellets are balance and rich in nutrition.

Cooling-Counter flow Pellet Cooler

The counter flow pellet cooler is used for cooling the feed pellets just coming out from the oil coating machine. It takes advantage of counter current cooling principle to cool the pellets with high temperature and high humidity. It can avoid the shock cooling phenomenon when the cold air contacts with the hot material, thus preventing the pellet appearance crack.

Packaging-Feed Pellet Packing Machine

As the last step in floating fish feed pellet line, packaging is optional according to your needs. The automatic feed pellet packing machine is always combined with the transport mechanism and the sewing machine to constitute the automatic feed pellet weighing and packing system used in animal feed factories.

Tips: How to Improve Water Stability of Floating Fish Feed Pellets

1. Using finely ground ingredients so that the small cavities on the surface of the pellets are filled up, thereby reducing the rate at which water is able to penetrate into the pellet.

2. Increasing the compaction of the mixture by applying more force during pelleting.

3. Cooking the mash or the moist pellets (e.g. by steaming) thus increasing.

4. Avoiding high concentrations of fat, water repellent or highly absorbing water ingredients in the diet mixture.

5. Using binders.

Welcome to know more about our fish feed extruder mahine/fish feed making plant.