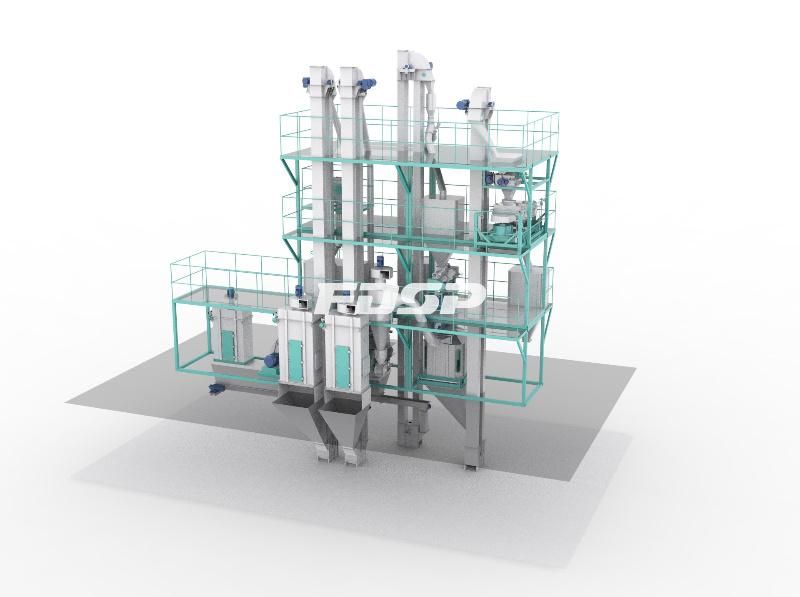

3-5tph Poultry Feed Plant Cattle Feed Mesh Plant Pellet Mill Line

Jiangsu Liangyou Zhengda Co., Ltd.- Type:Pellet Mill

- Processing Object:Cereals

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:With Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

- Pellet Mill Type:Ring Die Pelleter

Base Info

- Model NO.:FDSP

- Condition:New

- Applicable Materials Shape:Granular

- Output:3-5t,H

- Application:for Making Pellet and Mash Feed

- Cleaning:Crushing-Mixing-Pelletizing-Cooling-Sieving

- Feed:for Livestock, Poultry Fee

- Transport Package:Pallet

- Specification:CE, ISO, SGS

- Trademark:Liangyou

- Origin:Jiangsu China

- HS Code:84361000

- Production Capacity:3-5tph

Description

Basic Info.

Model NO. FDSP Condition New Applicable Materials Shape Granular Output 3-5t/H Application for Making Pellet and Mash Feed Cleaning Crushing-Mixing-Pelletizing-Cooling-Sieving Feed for Livestock, Poultry Fee Transport Package Pallet Specification CE, ISO, SGS Trademark Liangyou Origin Jiangsu China HS Code 84361000 Production Capacity 3-5tphProduct Description

Supply 4-6tph poultry feed plant cattle feed mesh plant pellet mill lineJiangsu Liangyou Zhengda Co., Ltd is specialized in manufacturing feed machinery and engineering, we can offer customer complete machine solutions for livestock feed(pig and others) , poultry feed(chicken, duck, goose and others), ruminant feed(cattle, sheep and others), normal aqua feed(four major Chinese carps), special aqua feed(shrimp, crab and others), extruding aqua feed(floating and sinking fish feed, shrimp and others), premix feed(including various additives), pet food(cat food, dog food and others), we can meet customers' kinds of needs.

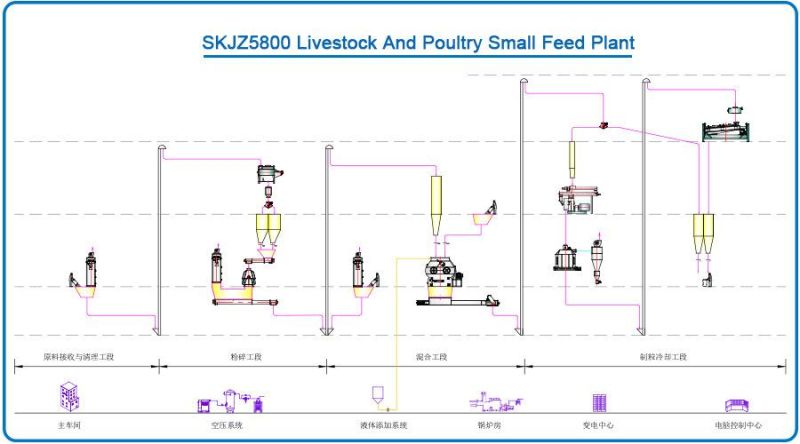

Now we take the case of SKJZ5800 feed set to make introduction based on process diagram and each process as follows:

Feed set definition:

Feed set is short for small manual batching modular feed set which capacity usually no larger than 5t/h. It adopts the design of building block system modular type which will be easy to dismounting, transportation and assembly. Low investment, quick returns, compact structure, small occupy, low demand for land, low cost for construction, and customized design is also optional. The feed set is suitable for small feed factory and farm.

Brief introduction for flow process

SKJZ5800 Feed set adopts manual batching system with 5-6t/h output for mesh feed 4-5t/h output for pellet feed. The raw material should be weighed in advance before feeding into the production line through two different dumping hopper, in which the material need to be grinded should go into the hammer mill through granule inlet in batches, hammer mill use the pre-cleaner as the feeder, the material no need grinding will go into the production through powder inlet after weighed in advance, then mixed in mixer, the material after mixing can go into the FP bins directly to be mesh finished products. It can also go into the pelletizing process to be pelletized, cooled, and finally packed by manual weighing. The total power of the feed set is about 172Kw, dimension is : 13x6x11m, matching 0.5T boiler. The feed set use splicing type frame and is characterized by compact design and reasonable structure, and the satisfaction of environment protection requirements, meanwhile it can be directed to customers design.

Technical parameter:

Model | Total Power (kw) | Output (t/h) | Floor Area (m) (L× W ×H ) | Main Equipment |

| SKJZ1800 | 43.5 | 0.5-1.5 | 6 × 4× 8 | SFSP50.SLHY0.4,SZLH25.SNSZ80 |

| SKJZ3000 | 80 | Mash:3-4 Granule:0.5-2 | 8× 6 × 8 | SFSP568 22kw, SLHY0.6,SZLH25,SNSZ11×11 |

| SKJZ3800 | 136 | 2-4 | 8.5 × 7.5 × 11 | SFSP568 30kw,SLHY1, SZLH320,SKLN2.5, SSLG15×80,SFJH802C |

| SKJZ4800 | 145 | 3-5 | 9.5 × 8.5 ×12 | SFSP568 30kw,SLHY1, SZLH320,SKLN2.5, SSLG15×80,SFJH802C |

| SKJZ5800 | 191 | 4-6 | 10 × 9× 13 | SFSP668 55kw,SHSJ1, SZLH350 55kw,SKLN2.5, SSLG15×100,SFJH100×2C |

Technological process chart:

Technological characteristics and introductions:

RM receiving and cleaning process: granules and powder material will be put into the production line separately though two inlet, the granules will be screened and cleaned to remove impurities by pre-cleaner, then remove the iron before it go into the hammer mill, the powder material should be cleaned in advance.

Grinding process: adopts FDSP's tear circle hammer mill which can make both coarse grinding and fine grinding, the feeder is combined together with the pre-cleaner which can clean the material and also feeding into the hammer mill, variable frequency control, evenly feeding and equipped with pulse filter. Mechanical induct discharging. The process is simple and with low cost, it is suitable for small capacity and multi type of material's grinding.

Grinding machine: hammer mill SFSP568-II with power 37KW, output: 5-6t/h

Mixing process:there is pre-mixing bin upper the mixer which can make the feeding continuously when mixer working, the mixed material can go into the pre-pelleting bin and mesh feed bins separately to meet the requirement for producing mesh feed and pellet feed at same time.

Mixing equipment: double shaft paddle mixer SHSJ1 with 11kw, 500kg/P, homogeneityCV≤5%

Pelletizing process: adopt one pellet mill with single conditioner which is suitable for normal poultry feed and ruminant feed production. the material go into the cooler directly after pellet mill, then go into the crumbling and screening system through bucket elevator, manual packing at last.

Pelletizing equipment: pellet mill SZLH350 with 55kw, output:3-7t/h.( ¢3.5 normal broiler feed formula)

Cooling equipment: counter flow cooler SKLN2.5 with output 5-6t/h

Crumbler: SSLG15x100 with output 3-5t/h, it can crumble the large feed pellets into small pellets to produce small chicken grow seedling feed. the crumbler is designed with bypass system so the material can be go into the screener though by pass when no need to use crumbler.

Screening equipment: plan rotary screener SFJH80×2C with capacity 4-6t/h

Auxiliary system: liquid adding system could add oil into the mixer to improve feed palatability. Air compressing system is used to supply compressed air for pneumatic components.

The process can be optimized according to different customer needs:

1. Considering the small capacity demand, Instead of powder material cleaning system designed in this feed set, we choose manual pre-cleaning, but customer could require to add this cleaning system based on needs

2. There is mesh feed bins and pellet feed bins both in feed set, if customer do not need the mesh feed we can remove it.