Small Feed Line Poultry Feed Pellets Production Line

Jiangsu Liangyou Zhengda Co., Ltd.- Type:Feed Plant

- Processing Object:Beans

- Processing Technics:Mixing-before-Crushing

- Screen Mesh:With Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

- Pellet Mill Type:Ring Die Pelleter

Base Info

- Model NO.:SKJZ3000

- Condition:New

- Applicable Materials Shape:Granular

- Warranty:1 Year

- Total Power:75kw

- Model Number:Skjz3000

- Voltage:380V,415V,440V

- Dimension(L*W*H):8m*6m*8m

- Capacity:1-2t,H

- Pelleted Feed Size:1.5-18mm

- Application:for Making Feed Pellets

- Transport Package:Pallet

- Specification:CE, ISO, SGS

- Trademark:Liangyou

- Origin:Jiangsu China

- HS Code:8436100000

- Production Capacity:1-2t,H

Description

Basic Info.

Model NO. SKJZ3000 Condition New Applicable Materials Shape Granular Warranty 1 Year Total Power 75kw Model Number Skjz3000 Voltage 380V/415V/440V Dimension(L*W*H) 8m*6m*8m Capacity 1-2t/H Pelleted Feed Size 1.5-18mm Application for Making Feed Pellets Transport Package Pallet Specification CE, ISO, SGS Trademark Liangyou Origin Jiangsu China HS Code 8436100000 Production Capacity 1-2t/HProduct Description

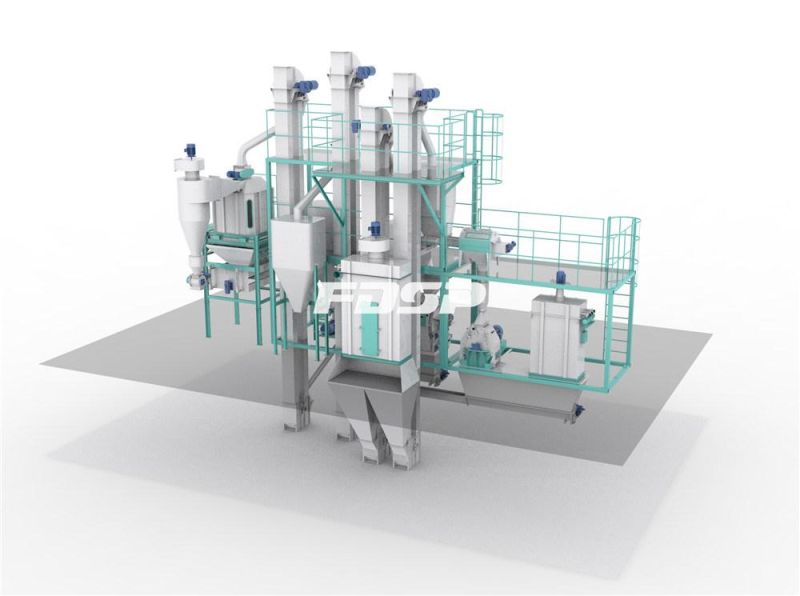

Small Feed Line Poultry Feed Pellets Production Line

Application

We supply aquaculture feed pellet mill, aqua feed machine, fish meal machine, fish feed equipment, shrimp feed pellet mill and so on. We are specialized in chicken feed making machine, poultry feed making machine, pig feed making machine, cattle feed making mahcine, etc

Product Feature

1. With reasonable technology, high capacity and low energy consumption. It can produce 2000-6000 tons mash and pellet feed per shift annually;

2. Modular Structure: The plant is compact, occupies less floor space and has low requirement on the mill tower, and needs low investment in civil works. The containerized modular structure is convenient for assembly and disassembly, facilitates the shipment and installation;

3. Centralized control: The analogue panel is adopted. All machines can be interlocked and safety, alarm device is available. The operation is simple and convenient;

4. Wide applicable scope: The plant can produce both poultry & livestock feed and fish feed and is applicable for medium and small sized feed mills and breeding farms.

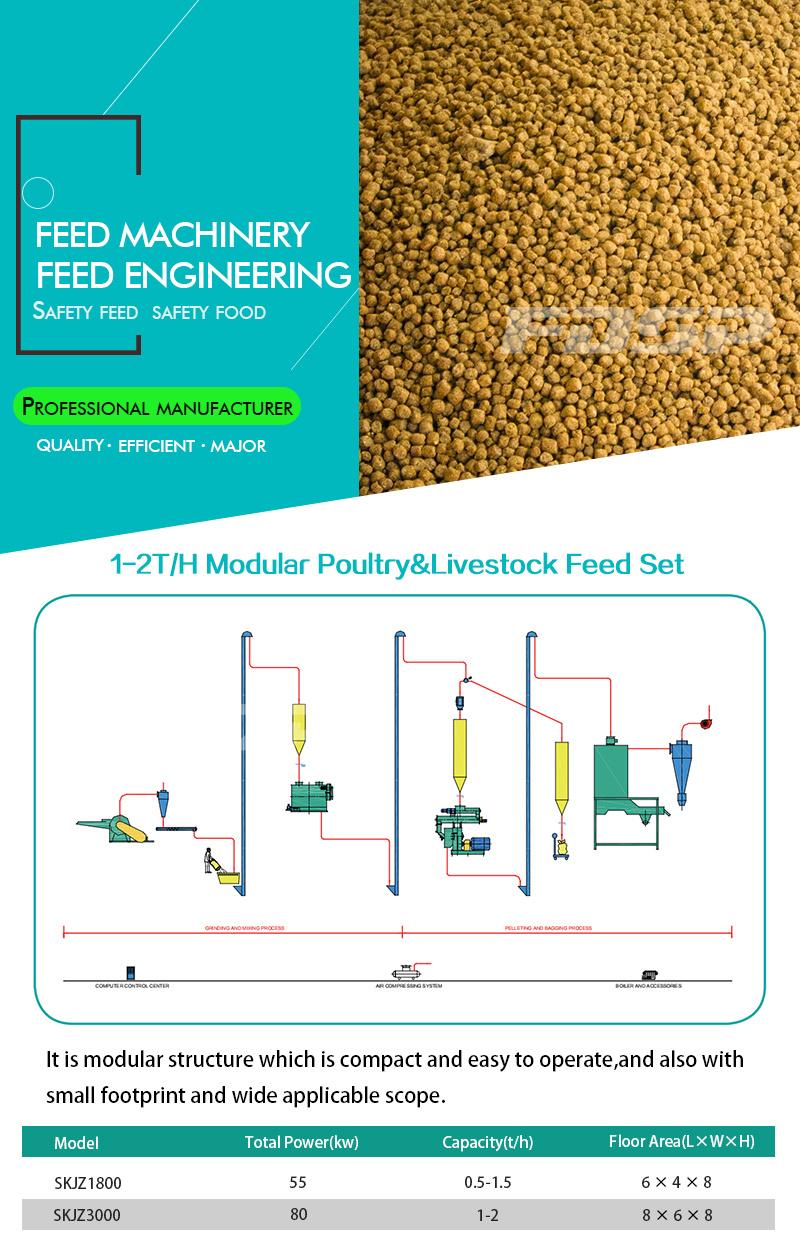

Performance Parameter

| Model | Total Power (kw) | Output (t/h) | Floor Area(m) (L*W*H) |

| SKJZ1800 | 55 | 0.5-2 | 6*4*8 |

| SKJZ3000 | 80 | 1-3 | 8*6*8 |

| SKJZ3800 | 136 | 2-4 | 8.5*7.5*11 |

| SKJZ4800 | 145 | 3-5 | 9.5*8.5*12 |

| SKJZ5800 | 191 | 4-5 | 10* 9*13 |

| SKJZ9800 | 281.7 | 5-8 | 12* 8* 16 |

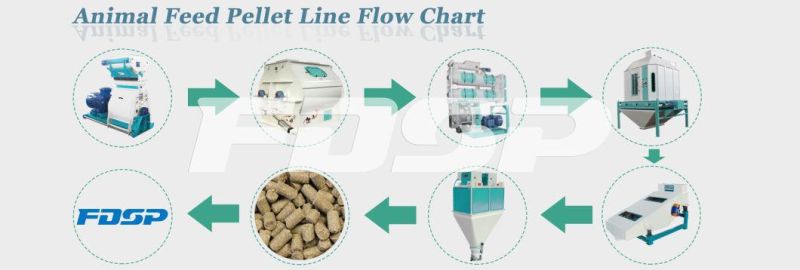

Feed Pellets Production Process:

RECEIVING AND PRECLEANING PROCESS--GRINDING PROCESS--BATCHING AND MIXING PROCESS--PELLETING PROCESS--BAGGING PROCESS--AUXILIARY SYSTEM--ELECTRIC CONTROL SYSTEM--MISCELLANEOUS

RM receiving and cleaning process:

Cleaning is playing a role to remove the impurities from raw material, including large impurities such as nonmagnetic impurity like rope, clod and corn cob, and magnetic impurity like iron nails. It will ensure the quality of products and safety of following processing machine.

Grinding process:

Grinding is playing a role to enlarge the surface area of feed which is good for digestion and absorption of animal, improve the material processing performance.Single hammer mill is used in this grinding process of feed set.

Mixing process:

Mixing is the process for all kinds of raw material to blend each other tightly so that they can be in homogeneous distribution under the external force after batching.

Pelleting process:

The purpose of pelletizer is to make use of the heat, moisture, and pressure in pelleting process to pelletize the feed which may be loose, easy to dust, with poor stability and hard to transport, then the feed could be with better stability, lower feed conversion rate, reduce feed waste and environmental pollution.

Cooling process

It can reduce the temperature and moisture of hot pellets. The main machine is Cooler.

This process can reduce the temperature and moisture of hot pellets, with low energy consumption, easy operation, high automation features.

Bagging process

Bagging Machine, according to customers' requirements, it can divided into small bagging machine and ton-bagging machine.Electronic quantitative packing scale is use the weighing sensor, weighting indicator and plate consist of control system. Automatic bagging scale has high measurement precision, high speed and low failure rate etc.

Brief Introduction of FDSP

FDSP is total solution provider mainly for feed industry and integrated with feed machinery, storage machinery, fertilizer machinery renewable energy machinery and its engineering. Taking "To create value for customers" as our motto, we are dedicated to provide elaborately-designed, economic & attractive, durable solution for our overseas customers.

Why choose FDSP?

We have passed Certificate for ISO9001, CE, SGS and our customers are enjoying with us in SEA, Middle East, Africa, Oceania, South America, etc. We have accumulated abundant experience for comprehensive development, utilization of agriculture.

We will become leader definitely for industry and strive to boost well-beings of society, be trustworthy, stable partner for long-term and create value for customers.

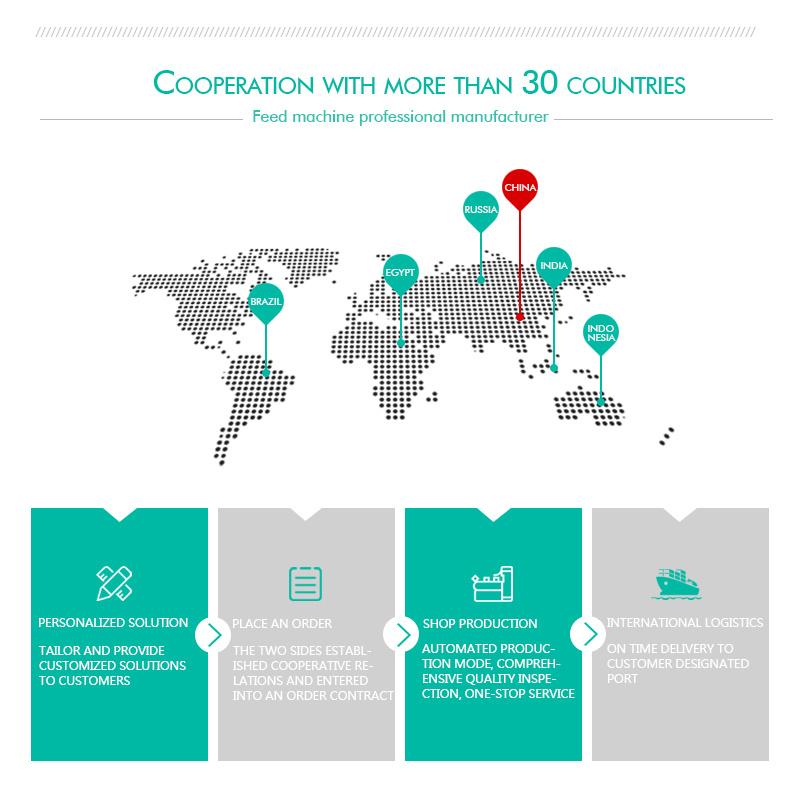

Exported Area

We have built business relationship with customers from more than 30 countries and region in SEA, Middle East ,Africa ,Europe ,Oceania and South America.

FAQ

FAQ1.Q:How can I trust on your quality?

Answer: 1). All of the machine be tested successfully in Liangyou workshop before shipment.

2). The working lifespan of Liangyou machines is at least 20 working years.

2. Q: Does your company provide Engineers Abroad Service?

Answer: Sure, we provide it. And we can provide free training for on-site workers.

3. Q: How to train our staff about operation and maintenance?

Answer : We will provide every detailed technical instructive, pictures, videos to teach them for the operation and

maintenance. In addition, our engineers for guide assembly will teach your staff on site.

4. Q:What shipment terms you offer?

Answer: We can offer FOB, CIF, CFR etc based on your request.

5. Q:What payment terms you take?

Answer: T/T, LC ,D/A,D/P

Welcome to contact us freely!