Min. Capacity Animal Feed Hammer Mill

Jiangsu Liangyou Zhengda Co., Ltd.- After-sales Service:Engineer Available

- Type:Hammer Mill

- Processing Object:Beans

- Processing Technics:Grinding System

- Screen Mesh:Without Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

Base Info

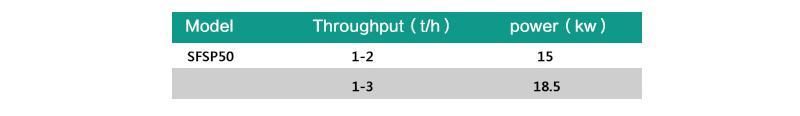

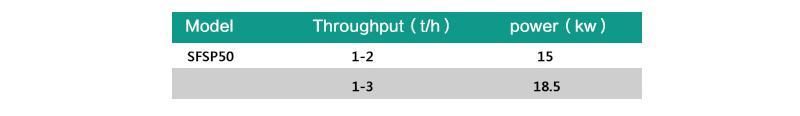

- Model NO.:SFSP50

- Pellet Mill Type:Ring Die Pelleter

- Condition:New

- Applicable Materials Shape:Granular

- Warranty:1 Year

- Power(Kw):15,18.5

- Output(T/H):1-2,1-3

- Voltage:380V 50Hz

- Material:Customized

- Transport Package:Pallet

- Specification:CE, ISO, SGS

- Trademark:Liangyou

- Origin:China

- HS Code:8436100000

- Production Capacity:1-3tph

Description

SFSP5015 1-2 18.5 1-3

Grinding: Grind the raw materials into required size for further processing in

poultry feed production.

Related machine: Hammer Mill

1) Feed hammer mill adopts best improve the production efficiency and make

the high delicious poultry feed pellets. After grinding, the diameter of the final

products could be the optimal size for pelleting.

2) Both coarse and fine grinding are realized through adjusting the gap

between beater and screen.

Notes for key feed processing equipment using

There are many kinds of feed processing equipment, among which the key equipment affecting feed granulation is nothing but hammer mill, mixer, granulator. In today's increasingly fierce competition, many manufacturers to purchase advanced production equipment, but because the operation of the use of error, often occur equipment failure. Therefore, feed factory's correct understanding of the use of equipment attention is not to be ignored.

Hammer mill

Hammer mill generally have two types: vertical and horizontal. The main components of the crusher are hammer and screen, hammer need durable wear-resisting and certain toughness, also need balanced arrangement so as not to cause vibration.

Notes for using hammer mill:

1) check the lubrication condition of the connecting parts and bearings before starting the machine, run the machine for 2-3 minutes, start feeding after normal operation, stop feeding after finish the production, and run the machine for 2-3 minutes, and then shut down the motor after all the material in the machine has been emptied.

2) Change the direction immediately when hammer abrasion reach the centerline. If all four corners are worn to the center, a new hammer piece is required. Note: The original arrangement should not be changed when changing, and the weight difference between each set of hammer pieces should not exceed 5G, otherwise it will affect the balance of the rotor.

3) The Air Net System of the hammer mill is very important to improve the efficiency of grinding and reduce the dust. Pulse filter with good performance should be chosed. After each shift, clean the inside and outside of the dust remover, remove the dust, check, clean and lubricate the bearing regularly.

4) The materials should not be mixed with iron, gravel and other sundries. If there is abnormal sound during production , should timely shutdown and make inspection, troubleshooting.

5) the working current and the feeding amount of the feeder at the upper end of the crusher should be adjusted at any time according to the different materials to prevent the jam and increase the crushing amount.

Grinding: Grind the raw materials into required size for further processing in

poultry feed production.

Related machine: Hammer Mill

1) Feed hammer mill adopts best improve the production efficiency and make

the high delicious poultry feed pellets. After grinding, the diameter of the final

products could be the optimal size for pelleting.

2) Both coarse and fine grinding are realized through adjusting the gap

between beater and screen.

Notes for key feed processing equipment using

There are many kinds of feed processing equipment, among which the key equipment affecting feed granulation is nothing but hammer mill, mixer, granulator. In today's increasingly fierce competition, many manufacturers to purchase advanced production equipment, but because the operation of the use of error, often occur equipment failure. Therefore, feed factory's correct understanding of the use of equipment attention is not to be ignored.

Hammer mill

Hammer mill generally have two types: vertical and horizontal. The main components of the crusher are hammer and screen, hammer need durable wear-resisting and certain toughness, also need balanced arrangement so as not to cause vibration.

Notes for using hammer mill:

1) check the lubrication condition of the connecting parts and bearings before starting the machine, run the machine for 2-3 minutes, start feeding after normal operation, stop feeding after finish the production, and run the machine for 2-3 minutes, and then shut down the motor after all the material in the machine has been emptied.

2) Change the direction immediately when hammer abrasion reach the centerline. If all four corners are worn to the center, a new hammer piece is required. Note: The original arrangement should not be changed when changing, and the weight difference between each set of hammer pieces should not exceed 5G, otherwise it will affect the balance of the rotor.

3) The Air Net System of the hammer mill is very important to improve the efficiency of grinding and reduce the dust. Pulse filter with good performance should be chosed. After each shift, clean the inside and outside of the dust remover, remove the dust, check, clean and lubricate the bearing regularly.

4) The materials should not be mixed with iron, gravel and other sundries. If there is abnormal sound during production , should timely shutdown and make inspection, troubleshooting.

5) the working current and the feeding amount of the feeder at the upper end of the crusher should be adjusted at any time according to the different materials to prevent the jam and increase the crushing amount.