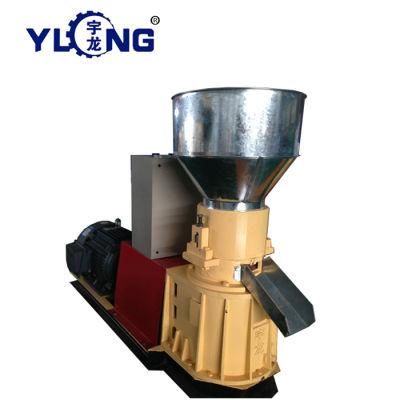

Flat Die Mini Feed Pellet Mill for Sale

SHANDONG BISON MACHINE CO., LTD.- Type:Pellet Mill

- Processing Object:Mixed Feed

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:Without Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

- Pellet Mill Type:Flat Die Pelletizer

Base Info

- Model NO.:SKJ200

- Bulking Machine Type:No

- Expanding Method:No

- Condition:New

- Applicable Materials Shape:Powder

- Name:Flat Die Mini Feed Pellet Mill

- Usage:Produce The Animal Feed Pellet

- Die Type:Flat Die

- Roller Material:Abrasion-Resistant Alloy

- Pellet Size:2-8mm

- Transport Package:Standard Sea Worthy Export Package

- Specification:CE, SGS, ISO

- Trademark:YULONG

- Origin:Jinan, Shandong, China

- HS Code:84793000

- Production Capacity:20nos Per Month

Description

Basic Info.

Model NO. SKJ200 Bulking Machine Type No Expanding Method No Condition New Applicable Materials Shape Powder Name Flat Die Mini Feed Pellet Mill Usage Produce The Animal Feed Pellet Die Type Flat Die Roller Material Abrasion-Resistant Alloy Pellet Size 2-8mm Transport Package Standard Sea Worthy Export Package Specification CE, SGS, ISO Trademark YULONG Origin Jinan, Shandong, China HS Code 84793000 Production Capacity 20nos Per MonthProduct Description

Flat Die Mini Feed Pellet Mill for SaleFeatures:

1. SKJ series small animal feed pellet is flat die, which are consisted of two rollers. Animal feed pellet machine is generally for home use. Animal feed pellet machine are widely

used in pressing feed pellets.

2. The animal feed pellet machine can press 2-8mm diameter animal feed pellets. Animal feed materials such as grain, soybean, maize etc.

3. Animal feed pellet machine is handled by CNC machine, the die and rollers are handled by heat treatment, which increase the abrasive resistance, prolong the die and rollers lifespan.

Advantages:

1. Low energy consumption and less manpower

2. Potential for 24 hour continuous running(stable and durable functionality)

3. Durable spare parts

4. Simple automated operation

5. Easily maintained

6. The flat die pellet mills are easier to clean than the ring die pellet mill

7. Able to change die and roller faster and easily.

8. Small and lightweight, making small-scale production

9. Visibility: It is possible to view into the chamber when pelletizing, so you can solve any problem in time.

Technical parameters:

| Model | Capacity(t/h) | Power(kw) | Pellet diameter(mm) | Weight(t) | Dimension(mm) |

| SKJ120 | 0.07-0.1 | 3 | 2-8 | 0.05 | 1150×300×550 |

| SKJ150 | 0.1-0.3 | 7.5 | 2-8 | 0.15 | 1260×400×650 |

| SKJ200 | 0.3-0.5 | 11 | 2-8 | 0.2 | 1300×500×850 |

| SKJ250 | 0.4-0.7 | 15 | 2-8 | 0.5 | 1400×600×1000 |

| SKJ280 | 0.5-0.8 | 22 | 2-8 | 0.65 | 1760×670×1600 |

| SKJ300A/B | 0.6-1 | 30/22 | 2-10 | 0.85 | 1860×670×1600 |

| SKJ2-350 | 0.6-1 | 37 | 2-8 | 1.1 | 1700×640×1620 |

| SKJ2-450 | 1-1.5 | 45 | 2-10 | 1.58 | 1740×830×1480 |

| SKJ3-350 | 0.8-1.4 | 37-4 | 4-10 | 2.08 | 1763×610×1780 |

| SKJ3-450 | 1-2 | 55-4 | 4-10 | 4.3 | 2300×1100×1900 |

| SKJ3-550 | 2-3 | 55 | 4-12 | 5.5 | 2200×1000×2200 |

| SKJ3-800 | 3-5 | 130-160 | 4-12 | 6.8 | 3200×1235×2700 |