Fully Automatic Baling Machine Commissioning in Waste Paper Plant

GUANGZHOU PANYU QIANGYE MACHINERY CO., LTD.- Type:Hydraulic Machine

- Automatic Grade:Automatic

- Power Source:Hydraulic

- Warranty:1 Year

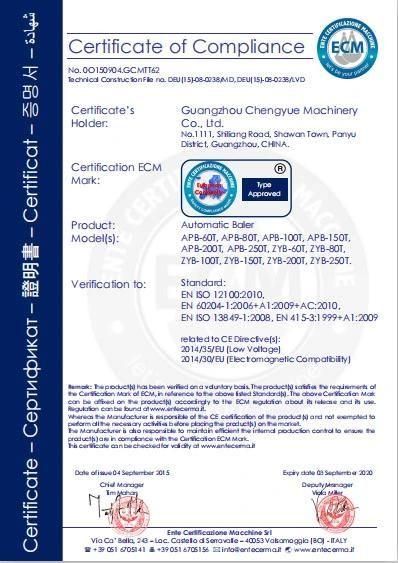

- Certification:ISO, CE

- Bale Size:1500*1200*1400 (Length Adjustable)

Base Info

- Model NO.:ZYB-150T

- Working Pressure:2500 Kn

- Motor Power:45*2+18.5 Kw

- Conveyor Power:7.5-11 Kw

- Capacity:22-26 Bale,Hr

- Overall Dimension:10600*4680*5200 mm

- Space for Installation of Conveyor:13780*16320*5200 mm

- Gross Weight:38000kgs

- Transport Package:Plastic Film

- Specification:10600*4680*5200(mm)

- Trademark:QIANGYE

- Origin:China

- HS Code:8422400000

- Production Capacity:30 Pieces,Year

Description

Basic Info.

Model NO. ZYB-150T Working Pressure 2500 Kn Motor Power 45*2+18.5 Kw Conveyor Power 7.5-11 Kw Capacity 22-26 Bale/Hr Overall Dimension 10600*4680*5200 mm Space for Installation of Conveyor 13780*16320*5200 mm Gross Weight 38000kgs Transport Package Plastic Film Specification 10600*4680*5200(mm) Trademark QIANGYE Origin China HS Code 8422400000 Production Capacity 30 Pieces/YearProduct Description

FULLY AUTOMATIC HORIZONTAL PRESS BALERSAVE TIME, LABOR & MONEY WITH A COMPLETE TURN-KEY SOLUTION FOR YOUR BALING NEEDS.

PRODUCT DESCRIPTION

Full Automatic Press Balers are Most Commonly Used for The Compaction of Large Waste and Recycling Material. They are Ideal for Distribution Centers, Waste Disposal Companies, Processing Industry and Paper Industry.

The Fully Automatic Balers are Usually Continuously Fed on a Variety of Systems eg Conveyor Belt, Forklifts or Suction Units. They are Suitable for Baling a Wide Range of Materials Including Paper, Cardboard, PET and Composite Materials.

STANDARD FEATURES INCLUDE

*Wire Tie Systems Automatic Tier

*Chamber with SWEDEN HARDOX 500 Replaceable Wear Liners (Track-Way Plates).

*Japan Mitsubishi PLC and Chinese Famous Brand LCD Display.

*USA Vickers Oil Pump.

*Left-hand or Right-hand Eject For Option.

Operator-Free Operation

*Hydraulic Reservoir with Regenerative Circuit.

*Bale chamber penetration

*One Spool of 12 Gauge Ultra High Tensile Galvanized Wires.

*Sandblasted, Primed, and Painted Blue for Long Lasting Durability.

*With Eject Cylinder

*Available with Integrated Conveyors with Rubber or Steel Belts for a Turn-key System.

*Special distributed scissors design to improve cutting efficiency and extend machine lifetime.

*Adjustable length of bale.

*Particular anti-slide design to make nicer bales.

INSTALLATION

If the buyer requires the seller to install the baler on site, the seller will send their engineers with salesman to install.

The buyer shall provide and bear round air ticket, Visa fee, accommodation, transportation and food at buyer's country etc. costs and expenses.

Once goods delivered, the seller will focus on the engineers' visa and once the buyer receives the machines, they will leave for installation.

Our engineers' installation is free of charge, which is USD0/per day;

The buyer is in charge of unloading the baler machine, putting baler machine in place, adding oil, and providing electricity; if the above mentioned points are well prepared, normally it will need one week for us to finish the installation and commissioning work.

Our engineer will provide free training to make sure safe operation on the whole set system.

WARRANTY & AFTER-SALE SERVICE

All above machines are guaranteed for 1 year after installation and commissioning. Within this warranty period, we will provide free major and minor spare replacement components for any malfunction due to manufacturer's defect. Every machine has been commissioned, debugged and passed our in-house inspection before leaving our factory. Technical support is available for the entire lifespan of the machine, if you need any assistance, we will provide solutions via various means like email, phone call, video conference etc. within 24 hours.

SHIPMENT

We can provide Door to Door delivery service.

CERTIFICATIONS

EXHIBITIONS ATTENDED

SUCCESSFUL CASES

| Model | Capacity | Bale Weight | Bale Qty | Bale Size(L*W*H) |

| ZYB-60T | 4 to 6 Tons/hr | 250 to 300 KGS | 18 to 20 Bales/hr | (800-1800)*914*660 |

| ZYB-80T | 6 to 8 Tons/hr | 350 to 400 KGS | 18 to 20 Bales/hr | (800-1800)*914*914 |

| ZYB-100T | 7 to 9 Tons/hr | 420 to 450 KGS | 18 to 20 Bales/hr | (800-1800)*914*914 |

| ZYB-120T | 7 to 10 Tons/hr | 430 to 500 KGS | 18 to 20 Bales/hr | (800-1800)*914*914 |

| ZYB-150T | 12 to 16 Tons/hr | 700 to 800 KGS | 18 to 20 Bales/hr | (800-1800)*1100*914 (800-1800)*1100*1000 (800-1800)*1100*1100 (800-1800)*1100*1300 |

| ZYB-200T | 14 to 18 Tons/hr | 800 to 900 KGS | 18 to 20 Bales/hr | (800-1800)*1100*1100 (800-1800)*1100*1300 |

| ZYB-250T | 21 to 26 Tons/hr | 1200 to 1300 KGS | 18 to 20 Bales/hr | (800-1800)*1200*1300 |

Note: capacity is based on plastic materials.

Bale size can be changed as per buyer's request.