Tilapia Floating Fish Feed Extruder

ZHENGZHOU YUFENG HEAVY MACHINERY CO., LTD.- After-sales Service:After Sales and Accessories Support

- Type:Pellet Mill

- Processing Object:Animal-Derived Feed

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:Without Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

Base Info

- Model NO.:DGP80B

- Pellet Mill Type:Screw Granulator

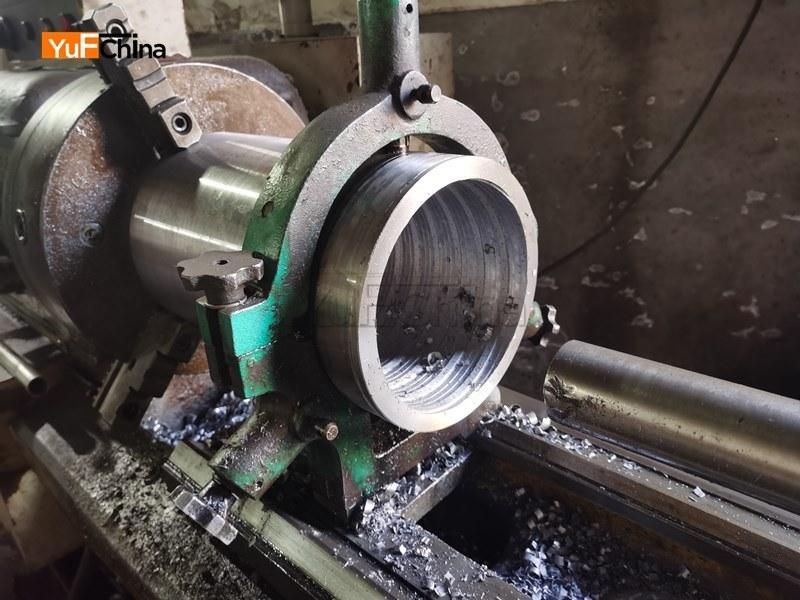

- Bulking Machine Type:Sigle Screw Bulking Machine

- Expanding Method:Dry Expansion

- Condition:New

- Applicable Materials Shape:All

- Warranty:1 Year

- Color:Multi

- Usage of Pellet:Feed

- Usage:Feed Pellet Mill

- Pellet Size:0.9-12mm

- Power Type:Electricity

- Certification:CE, ISO

- Advantage:High Efficiency

- Automatic:Yes

- Host Power:22kw

- Capacity:200-300kg,H

- Transport Package:Wooden Case

- Specification:warranty: 1 year

- Trademark:YUFCHINA

- Origin:Henan China

- HS Code:84833800

- Production Capacity:50 Sets Per Month

Description

Dry type Fish Feed Extruder

Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. With advanced single screw extruder by belt drive, floating fish feed machine is the ideal device in small and medium size feed processing plants and aqua farms.

Spotlights of the Dry Type Fish Feed Machine

1. The fish feed mill machine is widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made just by adjusting feed formulation.

2. Different molds can be chosen to make pellets by different diameters (0.9-15mm) and shapes.

3. Advanced technology and humanized design ensures easy operation and reliable performance, high efficiency, low power consumption.

4. Electric heating device is adopted to improve the feed expansion rate and pellets floating time.

5. Auto-temperature control system makes the temperature controlling more direct viewing and the parameter more precise.

6. High temperature and high pressure process can kill the salmonellosis and bacterial infections in materials and also makes the pellets easier to digest and absorb

7. Dry type fish feed extruder does not need the steam boiler, so the dry type pellet machine is cheaper and easier to use and operate compared with wet type pellet machine.

Working Principal of Dry Type Fish Feed Machine

There is no need of heating outside the dry type machine, through the screw extruding of the raw material, heat is produced and gathered during the rotary working process in the airtight environment, and during the high temperature ripening process, the starch and fiber of the raw material become swell. Then under the pressure-tight condition, material will be formed into pellets by shaping mould. At the end, through the high pressure produced by the regular rotating of the screw, after being cut by the forepart cutter which rotates regularly and high-speedily, the finished products will be shrunk and become small average puffed balls in room temperature and pressure.

| Name | Capacity (t/h) | Host power (kw) | Feeding power (kw) | Spiral diameter (mm) | Cutting power (kw) |

| DGP40-C | 0.03-0.04 | 5.5 | 0.4 | Φ40 | 0.4 |

| DGP50-C | 0.06-0.08 | 11 | 0.4 | Φ50 | 0.4 |

| DGP60-C | 0.12-0.15 | 15 | 0.4 | φ60 | 0.4 |

| DGP70-B | 0.18-0.2 | 18.5 | 0.4 | φ70 | 0.4 |

| DGP80-B | 0.2-0.3 | 22 | 0.6 | φ80 | 0.6 |

| DGP90-B | 0.30-0.35 | 37 | 0.6 | φ90 | 0.8 |

| DGP120-B | 0.5-0.6 | 55 | 1.1 | φ120 | 2.2 |

| DGP135-B | 0.7-0.8 | 75 | 1.1 | φ133 | 2.2 |

| DGP160-B | 1-1.2 | 90 | 1.5 | φ155 | 3.0 |

| DGP200-B | 1.8-2.0 | 132 | 1.5 | φ195 | 3.0-4.0 |

Finished fish feed pellet

Material for fish feed pellet mill?

1.before making floating fish feed, you need crush raw materials into powder with fish feed crusher

2.raw materials can be:corn, wheat, soybean, grain, bone powder etc

3.raw materials need grind into 60-80 mesh ,raw materials moisture content:20-25%

4.Rice Dust:contain about 10-14%of protein and also contain vitamin B1, B2, B6 and small quantity of enzyme.

Our factory