Home Using Small Fish Feed Extruder

ZHENGZHOU YUFENG HEAVY MACHINERY CO., LTD.- After-sales Service:Installation and Technical Support, Drawings

- Type:Pellet Mill

- Processing Object:Animal-Derived Feed

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:Without Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

Base Info

- Model NO.:DGP40C

- Pellet Mill Type:Screw Granulator

- Bulking Machine Type:Sigle Screw Bulking Machine

- Expanding Method:Dry Expansion

- Condition:New

- Applicable Materials Shape:All

- Warranty:1 Year

- Color:Multi

- Usage of Pellet:Feed

- Usage:Feed Pellet Mill

- Pellet Size:0.9-12mm

- Power Type:Electricity

- Certification:CE, ISO

- Advantage:High Efficiency

- Automatic:Yes

- Capacity:30-40 Kg,H

- Main Power:5.5 Kw

- Fish Feed:Floating Type and Sink Type

- Transport Package:Wooden Case

- Specification:warranty: 1 year

- Trademark:YUFCHINA

- Origin:Henan China

- HS Code:84833800

- Production Capacity:50 Sets Per Month

Description

Fish Feed - Floating & Sinking Pellet

The single screw extruder offers a unique combination of quality output and low capital investment making it a cost effective solution for processing premium shaped products.

Flexibility to produce a wide variety of shapes and sizes are key features of this technology, with ability to make pellets as small as 1.5mm.

The resulting products are lower in post-extruded moisture, requiring less drying. Which provide benefits of less nutrient degradation and reduced operational and capital costs.

Advantage to adopt a fish feed mill machine ?

1. Fish feed pellets are the popular feed in modern commercial fish farming, providing balanced nutrition needed by fish stock and improving fish farm environment. Due to high price of feed pellets on the market, many farmers tend to purchase fish feed extruder to produce pellets by themselves to low the cost.

2. Storage: can be kept for two to three months when stored in a covered cool dry place.

3. Hygiene: expansion process can eliminate most bacteria. Low moisture content (about 10%) can prevent bacterial growth.

4. Nutrition: can be added with animal or plant protein, fish oil or other fats, vitamin complex and minerals required by specific fish species. It is highly nutritious and can effectively improve the health of fish stock.

5. Environmental impacts: using pellet feed of appropriate size and density can lower the loss rate and significantly mitigate the environmental pollution caused by the feed residues.

6. Pellet feed of different sizes and densities can be made to accommodate the needs of species in various growth stages and with different babits. By using pellet feed of the appropriate size and density, loss rate and environmental pollution caused by the feed residue can be significantly reduced.

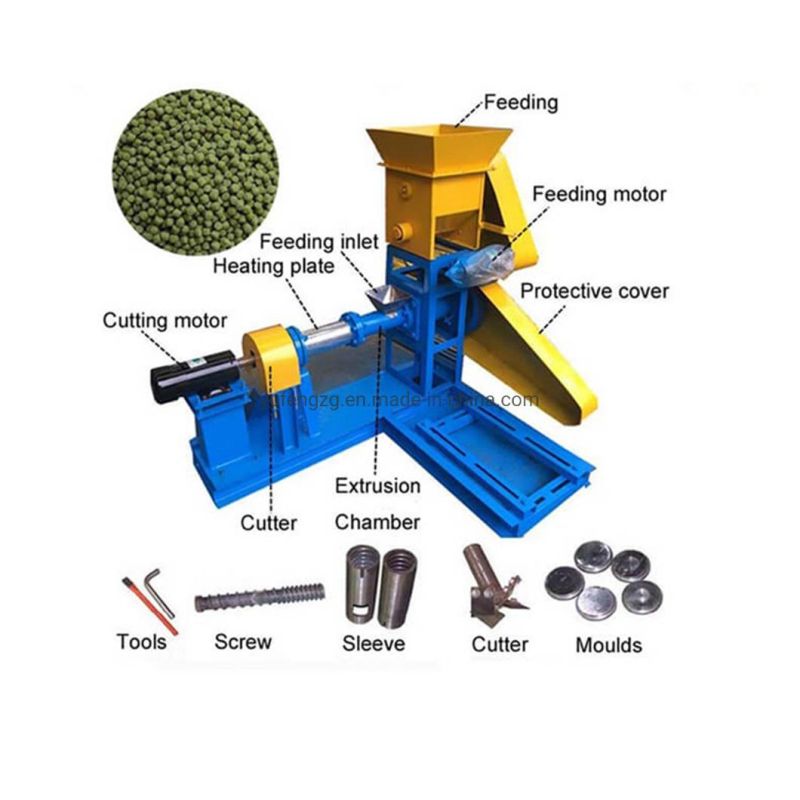

Dry type Fish Feed Extruder

Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. With advanced single screw extruder by belt drive, floating fish feed machine is the ideal device in small and medium size feed processing plants and aqua farms.

Spotlights of the Dry Type Fish Feed Machine

1. The fish feed mill machine is widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made just by adjusting feed formulation.

2. Different molds can be chosen to make pellets by different diameters (0.9-15mm) and shapes.

3. Advanced technology and humanized design ensures easy operation and reliable performance, high efficiency, low power consumption.

4. Electric heating device is adopted to improve the feed expansion rate and pellets floating time.

5. Auto-temperature control system makes the temperature controlling more direct viewing and the parameter more precise.

6. High temperature and high pressure process can kill the salmonellosis and bacterial infections in materials and also makes the pellets easier to digest and absorb

7. Dry type fish feed extruder does not need the steam boiler, so the dry type pellet machine is cheaper and easier to use and operate compared with wet type pellet machine.

Working Principal of Dry Type Fish Feed Machine

There is no need of heating outside the dry type machine, through the screw extruding of the raw material, heat is produced and gathered during the rotary working process in the airtight environment, and during the high temperature ripening process, the starch and fiber of the raw material become swell. Then under the pressure-tight condition, material will be formed into pellets by shaping mould. At the end, through the high pressure produced by the regular rotating of the screw, after being cut by the forepart cutter which rotates regularly and high-speedily, the finished products will be shrunk and become small average puffed balls in room temperature and pressure.

Wet type floating fish feed pellet making machine

Features of Wet Type Fish Feed Pelletizer

1. Boiler continuously offer hot steam into the conditioner, so materials can be fully cooked and the nutritional value is improved. Thus the quality and quantity of pellets can be improved greatly with lower power consumption.

2. High temperature and high pressure process can kill the salmonellosis and bacterial infections and also makes the pellets easily to digest.

3. Key parts are processed through vacuum quench treatment with high processing precision, thus have a long service life.

4. Screw sleeve adopts jacketed construction, which can be injected in with hot steam or cooling water, thus the extruding temperature can be controlled effectively.

5. Single-screw extrusion cooking: large production capacities; variable screw speeds.

6. Key parts are processed through vacuum quench treatment with high processing precision, thus have a long service life.

You can change different molds to make pellets with different diameters.

What is difference for Dry & Wet type Fish Feed Extruder?

1. Dry type fish feed extruder does not need the steam boiler and conditioner, so the dry type fish feed pellet machine is cheaper and easier to use and operate.

2. The feed pellet made by wet type fish feed pellet machine is more smooth and with better quality because the material is ripen and mixed enough in the conditioner compared with the dry type extruder.

3. The capacity of the dry type feed pellet machine is lower than the wet type fish feed pellet machine, so usually the dry type fish feed pellet machine is better and economic for the small and medium size user or factory.

4. Both dry type and wet type fish feed extruder can produce floating and sink feed pellet.

Dry Type floating fish feed pellet making machine

| Name | Capacity (t/h) | Host power (kw) | Feeding power (kw) | Spiral diameter (mm) | Cutting power (kw) |

| DGP40-C | 0.03-0.04 | 5.5 | 0.4 | Φ40 | 0.4 |

| DGP50-C | 0.06-0.08 | 11 | 0.4 | Φ50 | 0.4 |

| DGP60-C | 0.12-0.15 | 15 | 0.4 | φ60 | 0.4 |

| DGP70-B | 0.18-0.2 | 18.5 | 0.4 | φ70 | 0.4 |

| DGP80-B | 0.20-0.30 | 22 | 0.4 | φ80 | 0.6 |

| DGP90-B | 0.30-0.35 | 37 | 0.6 | φ90 | 0.8 |

| DGP120-B | 0.5-0.6 | 55 | 1.1 | φ120 | 2.2 |

| DGP135-B | 0.7-0.8 | 75 | 1.1 | φ133 | 2.2 |

| DGP160-B | 1-1.2 | 90 | 1.5 | φ155 | 3.0 |

| DGP200-B | 1.8-2.0 | 132 | 1.5 | φ195 | 3.0-4.0 |

Wet Type floating fish feed pellet making machine

| Name | Capacity (t/h) | Host power (kw) | Feeding power (kw) | Spiral diameter (mm) | Cutting power (kw) | Tempering power (kw) |

| DSP60-B | 0.18-0.2 | 15 | 0.4 | Φ60 | 0.4 | 0.75 |

| DSP70-B | 0.25-0.30 | 18.5 | 0.6 | Φ70 | 0.6 | 0.75 |

| DSP80-B | 0.35-0.40 | 22 | 1.1 | Φ80 | 0.8 | 1.1-1.5 |

| DSP90-B | 0.50-0.60 | 37 | 1.1 | Φ90 | 1.1 | 2.2 |

| DSP120-B | 0.70-0.80 | 55 | 1.1 | Φ120 | 1.5 | 2.2-3.0 |

| DSP135-B | 1.0-1.2 | 75 | 1.5 | Φ135 | 2.2 | 3.0-4.0 |

| DSP160-B | 1.8-2.0 | 90 | 2.2 | Φ155 | 2.2-3.0 | 4.0-5.5 |

| DSP200-B | 3.0-4.0 | 132 | 2.2 | Φ195 | 3.0-4.0 | 5.5 |

Finished fish feed pellet