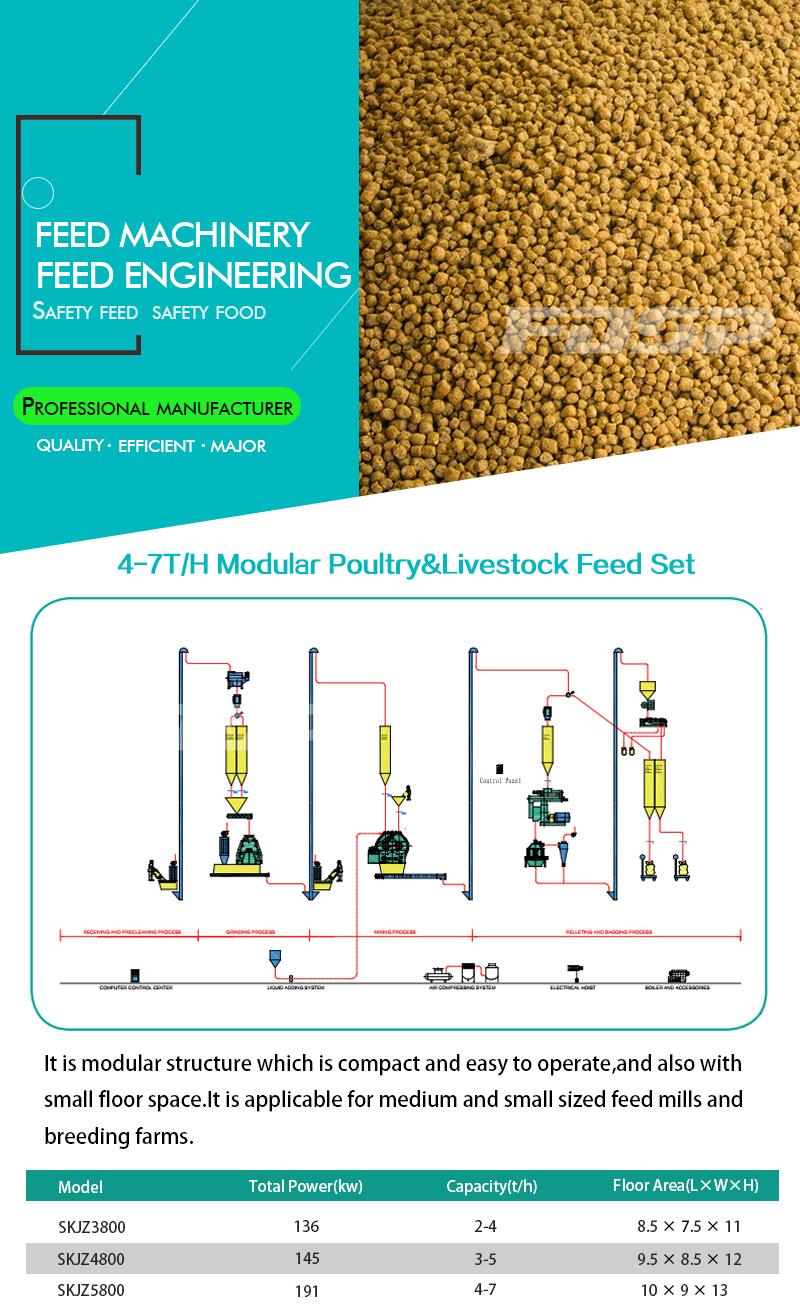

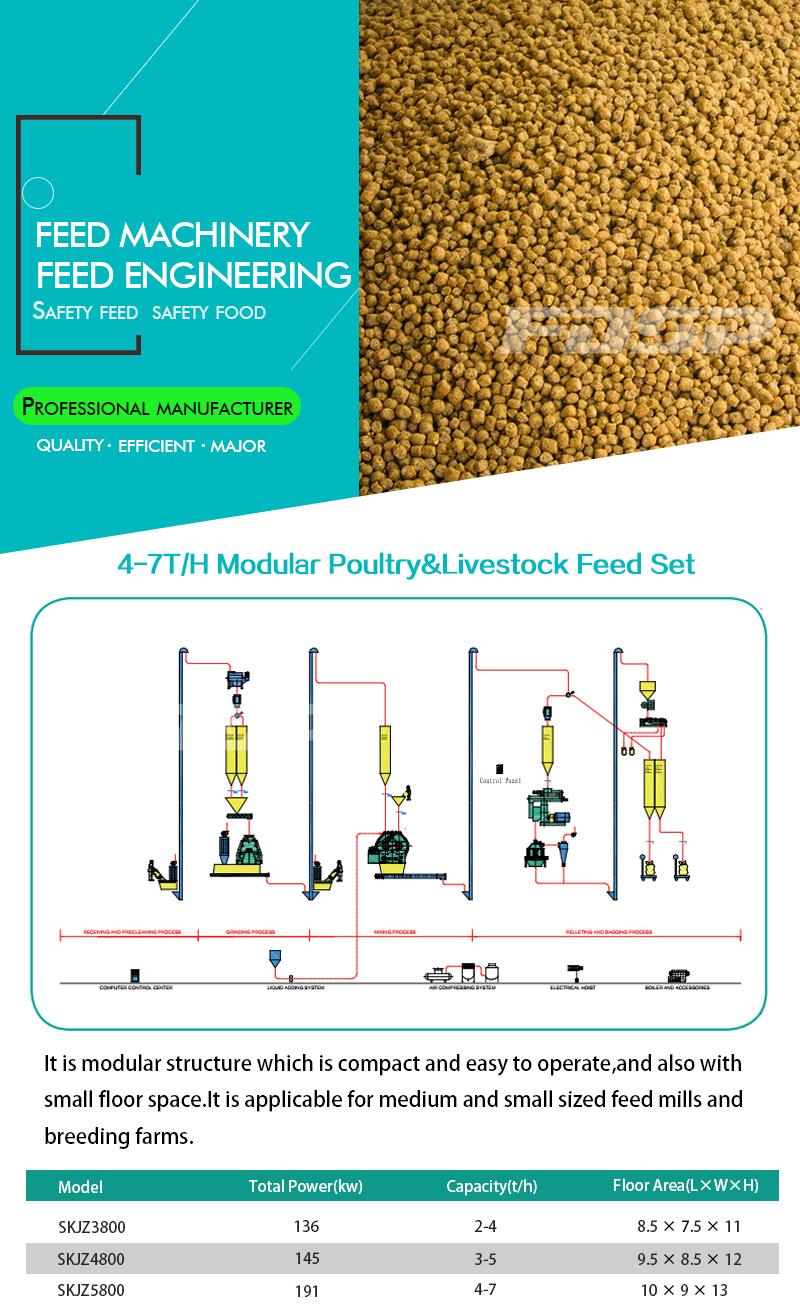

Animal Feed Pellet Production Processing Line

Jiangsu Liangyou Zhengda Co., Ltd.- Type:Feed Plant

- Processing Object:Beans

- Processing Technics:Mixing-before-Crushing

- Screen Mesh:With Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

- Pellet Mill Type:Ring Die Pelleter

Base Info

- Model NO.:4800

- Bulking Machine Type:Twin Screw Bulking Machine

- Expanding Method:Wet Expansion

- Condition:New

- Applicable Materials Shape:Granular

- Main Pellet Mill Power:160kw

- Output (T/H):10-15

- Main Motor:Siemens(China)

- Main Bearing:NSK,SKF

- Processing:Cusotmized

- Voltage:380-440V

- Batching Way:Automatic Batching

- Transport Package:Pallet

- Specification:CE, ISO, SGS

- Trademark:Liangyou

- Origin:Jiangsu China

- HS Code:8436100000

- Production Capacity:10-15t,H

Description

Overview

Product DescriptionDetailed PhotosOur Advantages

2)You can reduce the waste of feed pellets.

3)You can also store much more feed pellets in a much smaller storage space.

4) More convenient: you can use less time and manpower to make more feed pellets.

Installation Instructions

Hammer Mill - Mixer - Pellet Mill - Cooler- Crumbler - Rotary Screener - Bagging Scale - Control Center

Grinding: Grind the raw materials into required size for further processing in

poultry feed production.

Related machine: Hammer Mill

1) Feed hammer mill adopts best improve the production efficiency and make the high delicious poultry feed pellets. After grinding, the diameter of the final products could be the optimal size for pelleting.

2) Both coarse and fine grinding are realized through adjusting the gap between beater and screen.

Technical Parameters of the SFSP Series Circle Hammer millModel Power(kw) Capacity(t/h) Speed of Rotor(rpm) SFSP568 22/30/37 2-6 2940 SFSP668 37-250 4-50 2970 SFSP998 55-250 6-50 1480 SFSP999 90-200 15-50 1380

Mixing: evenly blend various kinds of raw material powder into uniform diet

Related machine: Poultry feed mixer

Double-shaft efficient mixing machine is widely employed in blending powdery materials in poultry feed industry to ensure compound poultry feed quality.

1) High mixing speed

2) Short mixing cycle

3)High homogeneous

Technical Parameters of the Double-shaft mixing machineModel Effective Volume

( m³) Capacity

(kg/batch) Mixing Time

(s) Homogeneity

(CV≤%) Power

(kw) SHSJ0.5 0.5 250

30-120

Time can be properly extended

according to different materials5 7.5 SHSJ1 1 500 5 11/15 SHSJ2 2 1000 5 18.5 SHSJ3 3 1500 5 22 SHSJ4 4 2000 5 30 SHSJ6 6 3000 5 37 SHSJ8 8 4000 5 45

Feed Pelletizing Process

forcing materials through holes in ring die to form compacted feed pellets which are then cut into a pre-determined size

Related machine: Poultry Feed Pellet Mill

The feed pellets produced by this poultry feed mill have rich nutrition, good palatability and high digestibility.

1)Low consumption, competitive price, long service life.

2)Driven by electric motor makes it more convenient and environmentally friendly

3)To make poultry feed pellets with different diameters, you just need to replace a

pellet mill die.

Technical Parameters of the pellet mill we supply

ModelCapacity(t/h) Power(kw) Inner diameter of Die(mm) SZLH32 2-5 37/45 320 SZLH350 3-7 55 350 SZLH400 3-10 75/90 400 SZLH420 3-14 90/110 420 SZLH508 6-15 160 508 SZLH678 11-32/11-36/11-40 220/250/280 678

Our service:

Package Delivery:

All our exported equipments are all firstly wrapped by the stretch film in case of scraping and then fixed in the iron pallet in case of shaking heavily in the container.

Customers visiting:

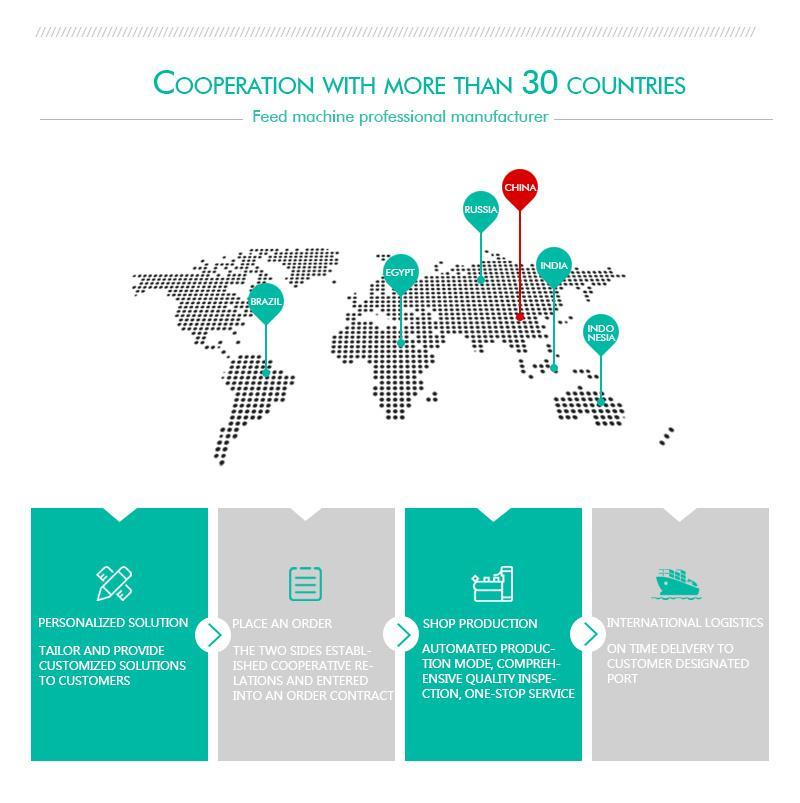

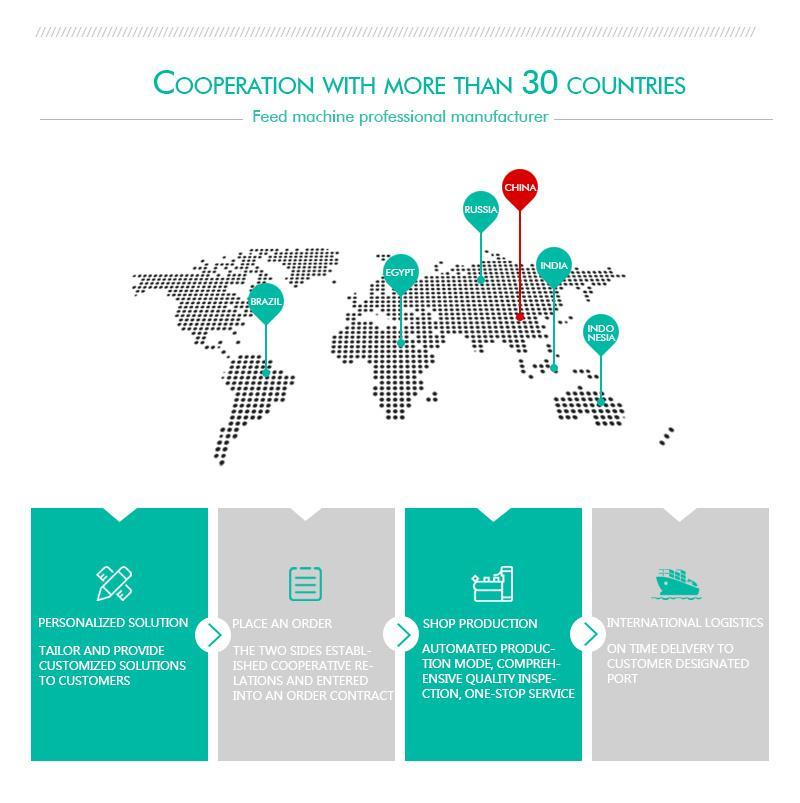

FDSP has exported Feed machinery to 30 countries including Korea, South Africa, Russia, Thailand, Taiwan, Philippines, Malaysia, Australia, Egypt, Syria, Nigeria, Ethiopia, India, Bangladesh, Pakistan, Iran etc.

Welcome customers from all around the world visiting.

Certifications

Certifications

1) You can add the necessary vitamins and minerals in exact amounts to feed pellets and you can be confident the animal has consumed them.

2)You can reduce the waste of feed pellets.

3)You can also store much more feed pellets in a much smaller storage space.

4) More convenient: you can use less time and manpower to make more feed pellets.

Installation Instructions

Main Process

Hammer Mill - Mixer - Pellet Mill - Cooler- Crumbler - Rotary Screener - Bagging Scale - Control Center

Grinding: Grind the raw materials into required size for further processing in

poultry feed production.

Related machine: Hammer Mill

1) Feed hammer mill adopts best improve the production efficiency and make the high delicious poultry feed pellets. After grinding, the diameter of the final products could be the optimal size for pelleting.

2) Both coarse and fine grinding are realized through adjusting the gap between beater and screen.

Technical Parameters of the SFSP Series Circle Hammer mill

Mixing: evenly blend various kinds of raw material powder into uniform diet

Related machine: Poultry feed mixer

Double-shaft efficient mixing machine is widely employed in blending powdery materials in poultry feed industry to ensure compound poultry feed quality.

1) High mixing speed

2) Short mixing cycle

3)High homogeneous

Technical Parameters of the Double-shaft mixing machine

( m³)

(kg/batch)

(s)

(CV≤%)

(kw)

30-120

Time can be properly extended

according to different materials

Feed Pelletizing Process

forcing materials through holes in ring die to form compacted feed pellets which are then cut into a pre-determined size

Related machine: Poultry Feed Pellet Mill

The feed pellets produced by this poultry feed mill have rich nutrition, good palatability and high digestibility.

1)Low consumption, competitive price, long service life.

2)Driven by electric motor makes it more convenient and environmentally friendly

3)To make poultry feed pellets with different diameters, you just need to replace a

pellet mill die.

Technical Parameters of the pellet mill we supply

Model

Our service:

Package Delivery:

All our exported equipments are all firstly wrapped by the stretch film in case of scraping and then fixed in the iron pallet in case of shaking heavily in the container.

Customers visiting:

FDSP has exported Feed machinery to 30 countries including Korea, South Africa, Russia, Thailand, Taiwan, Philippines, Malaysia, Australia, Egypt, Syria, Nigeria, Ethiopia, India, Bangladesh, Pakistan, Iran etc.

Welcome customers from all around the world visiting.

Certifications

CertificationsOur products have passed CE certification, SGS certification and ISO9001 certification. With our professional experienced technical team, we have lots of experience in overseas projects, and earned many certifications and patent design.