Vertical Shaft Pulverizer for Fine Grinding Feed Plant Machine

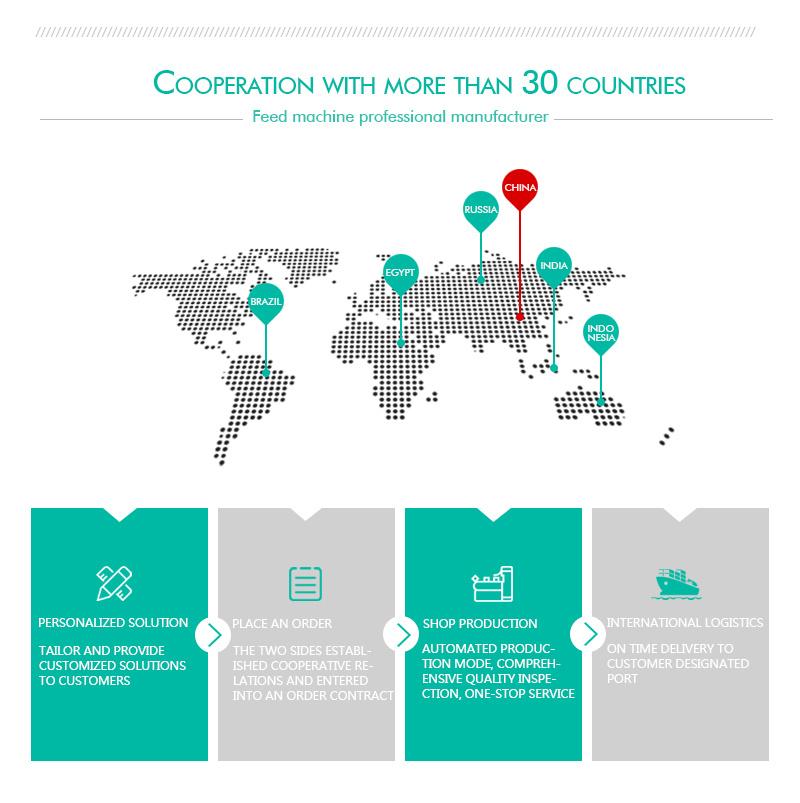

Jiangsu Liangyou Zhengda Co., Ltd.- After-sales Service:24hours

- Type:Grinding Equipment

- Processing Object:Beans

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:Without Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

Base Info

- Model NO.:SWFL series

- Pellet Mill Type:Ring Die Pelleter

- Bulking Machine Type:Twin Screw Bulking Machine

- Expanding Method:Wet Expansion

- Condition:New

- Applicable Materials Shape:Granular

- Warranty:1 Year

- Structure:Verticle

- Transport Package:Pallet

- Specification:CE, ISO, SGS

- Trademark:FDSP

- Origin:China

- HS Code:8436100000

- Production Capacity:1.2-5.5t,H

Description

Basic Info.

Model NO. SWFL series Pellet Mill Type Ring Die Pelleter Bulking Machine Type Twin Screw Bulking Machine Expanding Method Wet Expansion Condition New Applicable Materials Shape Granular Warranty 1 Year Structure Verticle Transport Package Pallet Specification CE, ISO, SGS Trademark FDSP Origin China HS Code 8436100000 Production Capacity 1.2-5.5t/HProduct Description

Vertical Shaft Pulverizer for Fine Grinding feed plant machineSWFL series vertical pulverizer is a kind of superfine pulverizing processing equipment. It is suitable for all kinds of large, medium and small feed mills. After primary screening, magnetic separation and mixing of various coarse materials such as corn, sorghum, rice, soybean meal, fish and shrimp ,the materials enter the pulverizer to achieve the required standard ultra-fine materials, especially suitable for ultra-fine pulverization of shrimp, turtle, carp and young animal feed.

Features:

1. Small vibration

The mesh structure enhances the overall strength and greatly reduces noise and vibration.

2. Low noise

A built-in dedicated muffler can greatly reduce noise and save space.

3. Efficient

The unique internal optimization structure of the machine improves the collision probability of materials and improves the hourly output. At the same time, the material selection is more precise and efficient, and the materials that are not easily crushed (such as soybean meal, bran, etc.) can also be effectively crushed;

4. Security

The hydraulic opening system reduces the labor intensity, easy maintenance, improves safety and shortens the maintenance period;

5. Weight removal and feeding system

Weight removal system, it can effectively remove 98% of raw material impurities (such as stones, iron, stainless steel, etc.). The feeding system feeds evenly and improves the generation of large currents during initial feeding.

6. Novel structure and stable performance

The machine adopts a non-screen structure, and the pulverization and grading are placed in the same confined space, so that the pulverization and grading are completed once, and the energy loss caused by over pulverization is reduced; the hammer design of the new structure has strong wear resistance and prolongs the use time, effectively reduce the cost of use; unique hammer mounting method, faster replacement of the hammer; unique arching device to prevent material arching during feeding.

7. Uniformly adjustable particle size

The pulverized particle size of 60-300 mesh is continuously adjustable, which can achieve ultra-fine pulverization with special requirements; use wind separation, transport, material temperature rise low.

Technical Parameters:

| Model Parameters | SWFL110 | SWFL130 | SWFL150 |

| Capacity (t/h) | 2-5 | 3-6 | 5-8 |

| Power Of Motor (kw) | 90 | 110 | 132/160 |

Product Show:

Package & Shipment

Our Company

FAQ:

1.Q:Are you a factory or trading company?

A:We are a manufacturing and trading company.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Liyang City, Jiangsu Province, China, near Shanghai.Our company is located in Nanjing City,Jiangsu Province,China.You can fly to Shanghai

airport directly.All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:How does your factory do regarding quality control?

A:"Quality is our soul. We always attach great importance to quality controlling from the beginning to the end. We have many engineers to R&D our products.

4.why choose our products?

A:Good products! Good reputation! Good service! Good price!