Complete Poultry Feed Plant Chicken Feed Machinery Line

Jiangsu Liangyou Zhengda Co., Ltd.- Type:Pellet Mill

- Processing Object:Cereals

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:With Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

- Pellet Mill Type:Ring Die Pelleter

Base Info

- Model NO.:FDSP series

- Bulking Machine Type:Sigle Screw Bulking Machine

- Expanding Method:Dry Expansion

- Condition:New

- Applicable Materials Shape:Granular

- Output:15t,H

- Application:for Making Pellet and Mash Feed

- Cleaning:Crushing-Mixing-Pelletizing-Cooling-Sieving

- Feed:for Aqua Feed

- Transport Package:Pallet

- Specification:CE, ISO

- Trademark:FDSP

- Origin:Jiangsu China

- HS Code:8438800000

- Production Capacity:15tph

Description

Basic Info.

Model NO. FDSP series Bulking Machine Type Sigle Screw Bulking Machine Expanding Method Dry Expansion Condition New Applicable Materials Shape Granular Output 15t/H Application for Making Pellet and Mash Feed Cleaning Crushing-Mixing-Pelletizing-Cooling-Sieving Feed for Aqua Feed Transport Package Pallet Specification CE, ISO Trademark FDSP Origin Jiangsu China HS Code 8438800000 Production Capacity 15tphProduct Description

Complete Poultry Feed Plant Chicken Feed Machinery Line

Definition of normal aqua feed:

The normal aqua feed is referred to the sinking pellet feeds needed for ordinary fish types( like four major Chinese carps).

Raw material:

Ordinary aquatic feed products are mainly protein raw materials, including grains, cake meal, rice bran, bran, blood meal, fat, antibiotics, vitamins and so on.

Introduction of process:

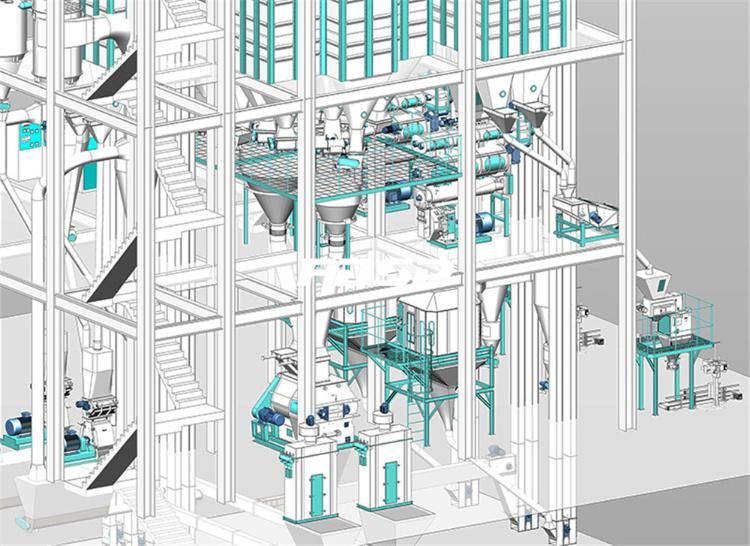

Ordinary of aquatic feed is characterized by fine grinding fineness (crusher mesh size 0.8- 2.0 mm), high curing conditioning requirements (using double jacketed conditioners), small product particle diameter (particle diameter of about 2-4.0 mm).The dual-line SZLH420 common aquatic fish feed project was designed to produce 12-16T/H, using two micro-crushing lines, one batching mixing line, two granulating lines and two packaging lines. The total power of the equipment is about: 770KW; The construction area of the production area is about 22x17.5x29m (high);allocated with 2T boiler. The whole line is with compact engineering design, reasonable structure, meeting environmental protection requirements, and can be designed according to customer requirements.

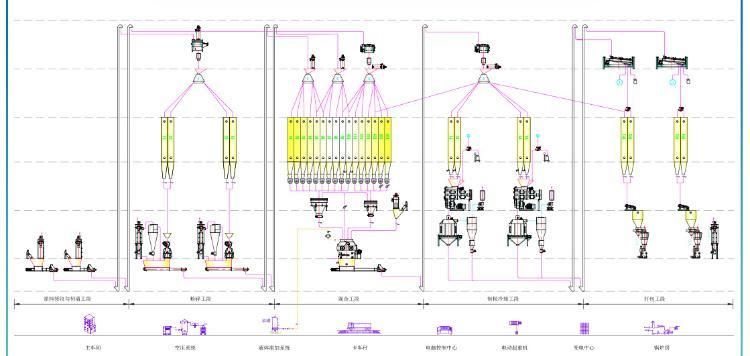

Process diagram:

Raw material receiving and cleaning process, grinding process, batching and mixing process, pelleting process, bagging process/ bulk packing, auxiliary process

1. Raw materials receiving and cleaning process:

In this section, pellet feeding cleaning and powder feeding cleaning are separated independently and separate dust removal. Dust removal effect is good.

Cleaning equipment:granules sifter SCY80,capacity 20-30T/H;powder cleaner: SQLZ60X50X100, capacity 10-15T/H.

2. Grinding process:

3. Mixing process:

4. Pelleting process:

5. Packing process:

There are 4 finished product bins in this section. The pellet or powder is automatically weighed and packed by the packing scale. Vibration sieve is arranged before packaging to screen out the powder in the finished material.

Packing equipment: Belt scale, packing range: 20-50kg/ bag, 6-8 bags/minute.

Auxiliary section: Dust removal system to improve workers' working environment; Grease adding system, common mixer place added to improve feed palatability.

FDSP Workshop

Packing & Shipping

About Us

Jiangsu Liangyou Zhengda Co., Ltd., specializing in the production of feed machinery and engineering, can provide customers with complete sets of equipment solutions for livestock feed (pig, etc.), poultry feed (chicken, duck, goose,etc.), ruminant feed (cattle, sheep, etc.), common aquatic feed (four major Chinese carps, etc.), special aquatic feed (shrimp, crab, etc.), extruded aquatic feed (floating and sink fish feed, shrimp feed, etc.), premix feed (including all kinds of additives, etc.), and pet food(cat food, dog food, etc.). to meet the different needs of customers.

Now take theDual-line SZLH420(15tph) normal aqua feed production line as a case, according to the process flow and each section to do the following introduction and description.

Certificate

Certificate FAQ

FAQ1.How does your factory do regarding quality control?

Our factory has gained CE, ISO9001, SGS authentication.'Quality is priority'. We always pay great attention on quality controlling from the beginning to the end.

2.How long is your guarantee?

One year. After this period we will definitely support you when needed. You are welcome to contact us at any time.

3.Will you send engineers to install the plant?

Yes, we can send our engineers do the guide installation overseas.

4.Where is your company located? How can I get there?

Our company is located in Nanjing City, Jiangsu Province, China, near Shanghai.

If you arrived Nanjing Lukou International Airport, you can come to our company by Car about 30 Mins. Or you arrive Shanghai Hongqiao Airport, you can by train about 1.5H.

5. Where is your factory located? How can I visit there?

Our factory is located in Liyang City, Jiangsu Province, China, near Shanghai; and our International Business Centre is in Nanjing City. You can fly to Shanghai airport or Nanjing Airport directly. All our clients, from home or abroad, are warmly welcome to visit us!