Factory Price Professional Triple Set 20 T/H Normal Fish Feed Production Line

Jiangsu Liangyou Zhengda Co., Ltd.- After-sales Service:Provided

- Type:Pellet Mill

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:With Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

- Pellet Mill Type:Ring Die Pelleter

Base Info

- Model NO.:SZLH420

- Bulking Machine Type:Twin Screw Bulking Machine

- Expanding Method:Wet Expansion

- Condition:New

- Applicable Materials Shape:Granular

- Warranty:1 Year

- Capacity(T/H):20

- Transport Package:Pallet

- Specification:2000 KG

- Trademark:FDSP

- Origin:China

- HS Code:8436100000

- Production Capacity:3-20t,H

Description

Basic Info.

Model NO. SZLH420 Bulking Machine Type Twin Screw Bulking Machine Expanding Method Wet Expansion Condition New Applicable Materials Shape Granular Warranty 1 Year Capacity(T/H) 20 Transport Package Pallet Specification 2000 KG Trademark FDSP Origin China HS Code 8436100000 Production Capacity 3-20t/HProduct Description

Factory Price Professional Triple Set 20 T/H Normal Fish Feed Production LineThe ordinary aqua feed is referred to the sinking pellet feed for ordinary fish types( like four major Chinese carps).

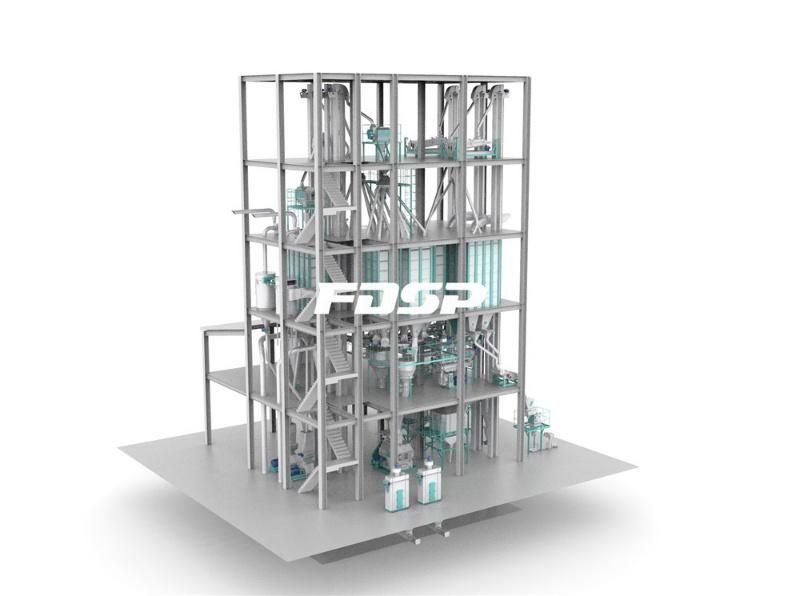

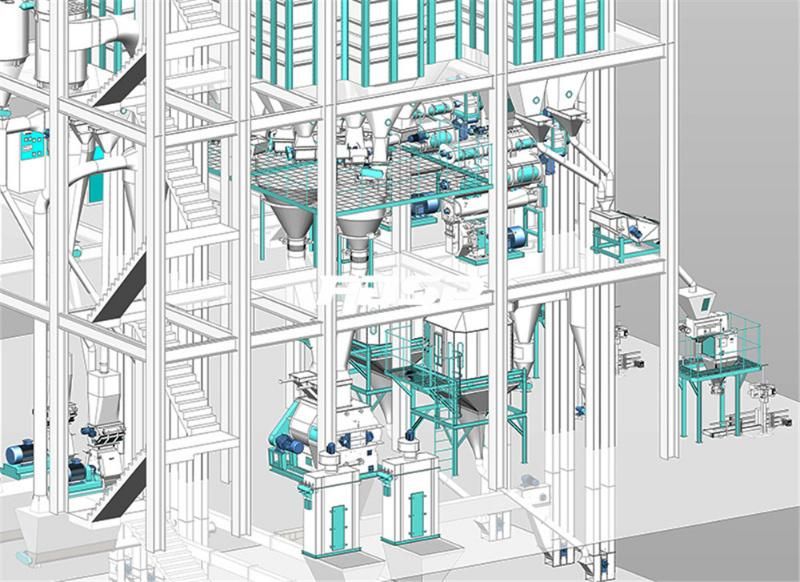

Process diagram:

18-24T/H 3set SZLH420 normal aqua feed plant process:

Raw material receiving and cleaning process--grinding process-- batching and mixing process--pelleting process--bagging process/ bulk packing-- auxiliary process.

Raw material:

Normal aqua feed mainly take protein as raw materials, including soybean cakes , rapeseed meal, rice bran, bran, blood meal, fat, antibiotics, vitamins and so on.

Introduction of process:

Ordinary aqua feed is characterized by fine grinding fineness (hammer mill screen size 0.8- 2.0 mm), high curing conditioning requirements (using double jacket conditioners), small pellet diameter (particle diameter of about 2-4.0 mm). The 3set SZLH420 normal aqua feed plant was designed to produce 18-24t /h, using three micro-crushing lines, two batching and mixing line,thee granulating lines and two packaging lines. The total power of the equipment is about :1100KW;The construction area of the production area is about 22.5x24.5x31.8m (high);allocated with 2T boiler. The 3set SZLH420 normal aqua feed plant with 18-24T/H capacity is with compact engineering design, reasonable structure, meeting environmental protection requirements, and can be designed according to customer requirements.

Process diagram:

Raw material receiving and cleaning process--grinding process-- batching and mixing process--pelleting process--bagging process/ bulk packing-- auxiliary process

Technological characteristics and introductions:

RM receiving and cleaning process:

In this process, the clean system for granule receiving and cleaning is separated from powder receiving and cleaning, dust collection are individual which is with the better effects.

cleaner: granule precleaner SCY100, output 30-40 t/h, powder cleaner SQLZ90×80×110, output 30-50 t/h.

Grinding process:

we use 3 set hammer mill with different power according to the different material characteristic. 2 grindings bins are equipped for each hammer mill to cross exchange different raw material crushing ; The impurities could be removed from raw material by magnetic separation equipment before grinding bins to ensure the safe running of hammer mill.

Grinding equipment(3 sets): hammer mill SFSP668×1000, 160 KW, output 6-8 t/h(1 set), hammer mill SFSP668×800, 110 KW, output 4-4.5 t/h(2 set)

Batching and mixing process:

In this process, we use 36pcs batching bins including 4 common bins. For each batching system two batching scale work at same time which is controlled by FDSP developed independently batching program, achieve accurate quick and slow feeding, quick batching and with high accuracy.

Weighing equipment: batching scale PCS15 /PCS10, weighing accuracy: dynamic≤3‰, static≤1‰.

Mixing equipment: mixer SHSJ3, (22KW,1500kg/batch), designed output 24-30t/h/set, homogeneity CV≤5%.

Granulation process:

Three set double conditioner pellet mill is used in this process. Two pellet bins are equipped for each pellet mill which is easy to change the formula. After granulation, the pellets enter into the cooler ,bucket elevator and then go to screening by rotary screener. The finished products go to the packing bins, others go back to the pellet mill other received by bags.

Granulation equipment(3 sets): SZLH420, 110 KW,output 6-8 T/H(¢4.0 mm grass carp feed). Cooling equipment(3 sets):SKLB4,volume 4 m3 output 6-8 T/H/set

Packing process:

There are 3 packing scale and 12 FP bins in this process. vibration screener is all equipped before packing scale to screen the powder in final pellets which can improve the feed pellet quality, the design also consider the bulk transportation.

Packing equipment: belt packing scale weighing rage 20-50kg/bag, 6-8bags /min.

Auxiliary process:

Dust collection system can improve the work condition, the oil adding system is usually seen in the mixer adding system which can improve the feed palatability.

The process can be optimized according to different customer needs:

1. Single point dust collection mode is used in the plan which means pulse filter is equipped for every rotary distributor (mesh) and granule cleaner with good effect. Single point dust collection is kind of humanized design of our company, to provide a better working environment, but the cost increases, customers can consider whether it is needed in actual situation;

2. The quantity of bins can be adjusted to achieve the beast use ratio and effectively control the production cost based on factors such as customers' formula, characteristics of raw materials.

3. The crumbler after cooler is optional, if the customer need to produce crumbled fish feed.