Rice Husk Straw Pellet Making Machine of Good Quality

Jiangsu Liangyou Zhengda Co., Ltd.- After-sales Service:Engineer Available

- Warranty:1 Year

- Structure:Horizontal

- Fuel Size:Particle

- Capacity(T/H):0.8-1.2

- Main Power(Kw):90

Base Info

- Model NO.:WZLH420

- Pellet Size(mm):6-8

- Power of Screw Feeder(Kw):2.2

- Voltage:380V

- Automatic Grade:Automatic

- Controlling Mode:Artificial

- Energy Saving:Energy Saving

- Customized:Customized

- Transport Package:Iron Pallet and Soft Guard

- Specification:CE, ISO9001, SGS

- Trademark:FDSP

- Origin:Jiangsu, China (Mainland)

- HS Code:8479300000

- Production Capacity:5 Sets,Month

Description

Basic Info.

Model NO. WZLH420 Pellet Size(mm) 6-8 Power of Screw Feeder(Kw) 2.2 Voltage 380V Automatic Grade Automatic Controlling Mode Artificial Energy Saving Energy Saving Customized Customized Transport Package Iron Pallet and Soft Guard Specification CE, ISO9001, SGS Trademark FDSP Origin Jiangsu, China (Mainland) HS Code 8479300000 Production Capacity 5 Sets/MonthProduct Description

Ring Die Wood Pellet Mill/Biomass Pelletizer Machine with CE/ISO

Introductions of wood pellet mill machine:

1. Biomass wood pellet machine is a kind of machine which could process sawdust

straw dust, rice husk, peanut shell, tree branches, etc biomass through pre-

treatment and process.Those biomass material will be solidified into high-

density pellet fuel.

2. Classification:Flat die wood pellet machine,horizontal ring die wood pellet

machine and vertical ring die wood pellet machine.Our horizontal ring die pellet

machine have high output than flat die wood pelletizer;compared with vertical

ring die pelletizer, our product have long term stable performance and easy

maintenance,the finished pellets with compact structure,so they can be applied

for industrial boiler.

Features of wood pellet mill machine:

1. High precision gear-driven transmission system, about 20% higher than belt

driving;

2. Siemens motor, imported bearing, Germany oil seal to ensure long service time;

3. Advanced frequency-conversion motor, overload protection device, magnetic

separating device are designed to ensure safety and long service time;

4. Advanced compensation type serpentine spring coupling to ensure high

efficiency, low noise and long service time;

5. Gear-box body adopts HT250 material, which makes it much more durable and

ensure its long service time;

6. Forced feeding system, specially designed for material with low density of 0.3-

0.6g/m3

7. Suitable for pelleting various raw materials including woodiness, biomass waste

like sawdust, woodchips, straw, stalk, sugar cane, napier grass, etc.

Technical Parameter of Wood Pellet Mill Machine:

| Item | Ring die wood pellet mill machine |

| Pellet Mill Type | - With Standard Feeder - With Anti-broken Feeder |

| Technical Parameters | - Capacity: 1.5-1.8(T/H) - Size: 3200*1100*1700(mm)- Power: 110/132kw- Inner diameter of die: 520(mm) - Pellet size: 6ø, 8ø, 10ø(mm) - Net weight: 4500(kg) |

| Main Features | - CE & ISO & SGS certification - Siemens motor, imported bearing - High precision gear-driven transmission system - One ring die and two rollers system |

| Optional Parts | - Screw feeder with anti-broken - Conditioner: To adjust the moisture of raw material. - Auto cooling system for gear-box(large capacity) |

| Packing Mode | Iron pallet with stretched film, etc |

| MOQ | 1 set |

| Payment | L/C, T/T, Western Union, Money Gram... |

| Warranty | 12 months |

Parameters of WZLH Series of wood pellet machine:

| Model | WZLH420 | WZLH520 | WZLH680 | WZLH780 |

| Capacity(t/h) | 0.8-1.2 | 1.5-1.8 | 2-2.5 | 2.5-3.5 |

| Main motor power(kw) | 75/90 | 110/132 | 160/185 | 200/220 |

| Feeder power(kw) | 2.2 | 3 | 4 | 4 |

| Ring diedia(mm) | 420 | 520 | 680 | 780 |

| Pellets dia(mm) | 6-8 | 6-8 | 6-8 | 6-8 |

Picture of wood pellet mill machine:

Application of wood pellet mill machine:

wood pellets is mainly made of any wood waste and biomass particles, such as wood sawdust, wood shavings, wood chips, wood logs, straw, rice husk, coffee husk, etc

Our Service:

1. Warranty:1 years

2. Our professional service includes: Free training, Guidance Installation and

Debugging.

3. After the warranty period, the supplier promise to provide life-long service for

customer, and provide the most preferential price of the required parts.

4. 24 hours online.We will reply your questions on time.

Successful Turnkey Projects of FDSP:

FDSP has sold Feed machinery and fertilizer machinery throughout China and exported to Korea, South Africa, Russia, Thailand, Taiwan, Philippines, Malaysia, Australia, Egypt, Syria, Nigeria, Ethiopia, India, Bangladesh, Pakistan, Iran etc.

A complete set of fertilizer production line with capacity of 10tph was exported to South Korea in 2008;

A complete set of pulverized coal pellet production line with capacity of 30t/h was exported to South Africa in 2009.

Three complete sets of feed production lines were exported to Egypt with capacity of 10tph, 15tph and 20tph respectively from 2010 to 2012.

A large model of pellet mill with capacity of 25tph was exported to Thailand in 2013.

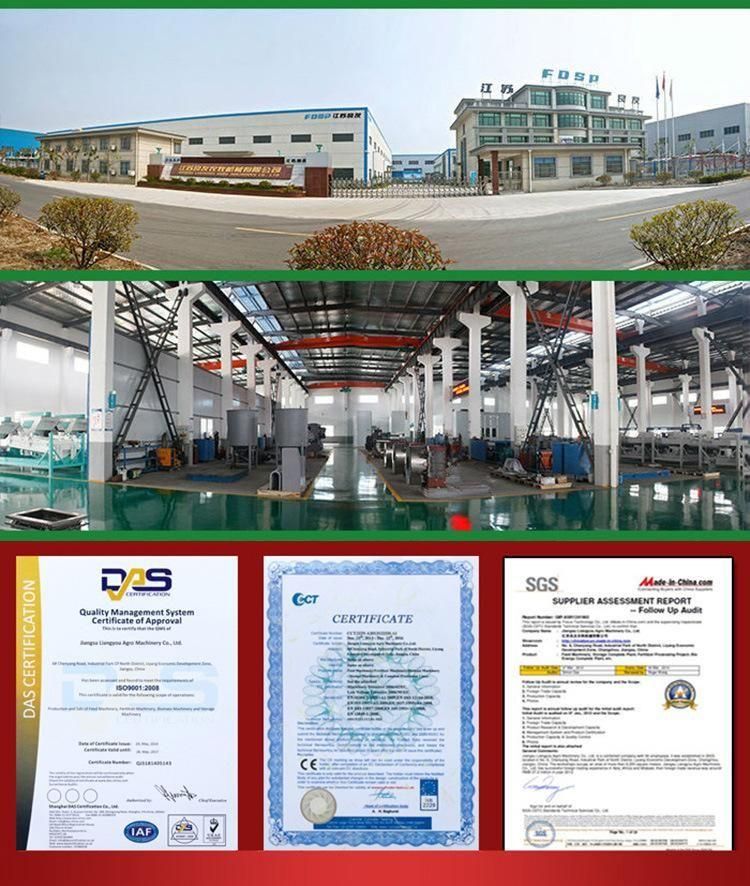

Our company view and certificates: