Best Complete Small Scale Farm Cheap Livestock Pig Cow Cattle Animal Chicken Poultry Feed Pellet Machine for Making Processing Milling Grass Fodder Production

ANYANG BEST COMPLETE MACHINERY ENGINEERING CO., LTD.- After-sales Service:1 Year

- Type:Pellet Mill

- Processing Object:Maize, Corn, Wheat Bran, Soybean Meal,Cake, Bone P

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:With Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

Base Info

- Model NO.:STLP-20211108

- Pellet Mill Type:Flat Die Pelletizer

- Condition:New

- Applicable Materials Shape:Granular

- Warranty:1 Year

- Pellet Diameter:2-8mm Feed Pellets

- Pellet Forming Rate:>90%

- Application:Manufacturing Feed Pellets

- Service:Oversea Feed Pellet Plant Custruction

- Transport Package:15000*4000*4500 mm

- Specification:15000*4000*4500 mm

- Trademark:ABC Machinery

- Origin:China

- Production Capacity:600~1000kg,H

Description

▸Title

▮ Technical parameters of STLP pellet mill

(Kw)

(kg/h)

(kg)

(mm)

▮ Technical parameters of STLP chicken pellet mill

★ Low requirement on floor space and workshop condition;

★ Direct use by easily connecting the machines, no need for civil engineering or complex intallation like welding;

★ Continuous production with easy operation, only 1-2 operator is needed.

★ Lower invest on project site, installation fees, and labor cost.

Contact Now for Catalogs & Best Price!

This flat die poultry pellet mill can be used for making chicken feed pellets, goat feed pellets, cattle feed pellets, rabbit feed pellets, fish feed pellets, dog feed pellets, etc., and is specially suitable for small or medium feed factory, breed farm or aquatic base.

It has the better raw material versatility, which can be suitable for pelletizing various raw materials such as corn, broomcorn, wheat, beans, oil seed meal, boine powder and so on. Also, this manufacturing plant for animal feed has the features of low energy consumption and high production efficiency for larger profits.

Contact Now for Catalogs & Best Price!

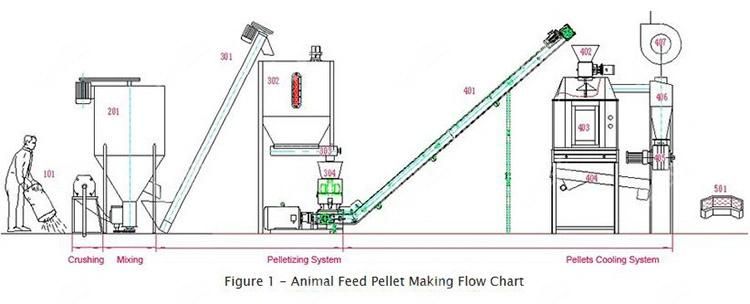

As shown in the above figure, the maize and soya bean meal (store & directly feed on ground) is sucked into the Grinding Machine 101 and crushed into fine powder. Any other powder/soft materials, such as wheat bran, bone meal, microelement, vitamin, etc, which don't need to be crushed, they can directly feed into the Vertical Mixing Machine 201 from its feeding port. All materials are mixed uniformly and discharged into the hopper of Screw Conveyor 301 then feed into Temporary Storage Silo 302 by screw conveyor. By Screw Feeder 303, the mixed materials are uniformly and continuously feed into the Pellet Mill 304 then produced into feed pellets. The pellets are discharged into the hopper of Belt Conveyor 401 then feed into the Pellet Cooling Machine 403 through Air Lock 402. With the cooling process, the fresh & hot pellets are cooled, the pellet temperature is not more 5 than the room temperature. The cooled pellets are screened by the Vibrating Screen 404, then they can be packaged.Contact Now for Catalogs & Best Price!

Contact Now for Catalogs & Best Price!