High Quality Animal Feed Production Line Poultry Feed Pellets Production Line

Jiangsu Liangyou Zhengda Co., Ltd.- Type:Complete Line

- Processing Object:Mixed Feed

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:With Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

- Pellet Mill Type:Ring Die Pelleter

Base Info

- Bulking Machine Type:Sigle Screw Bulking Machine

- Expanding Method:Dry Expansion

- Condition:New

- Applicable Materials Shape:Granular

- Output:6-8t,H

- Application:for Making Pellet and Mash Feed

- Cleaning:Crushing-Mixing-Pelletizing-Cooling-Sieving

- Feed:for Piglet Feed

- Transport Package:Pallet

- Trademark:Liangyou

- Origin:Jiangsu China

- HS Code:84361000

- Production Capacity:6-8tph

Description

Basic Info.

Bulking Machine Type Sigle Screw Bulking Machine Expanding Method Dry Expansion Condition New Applicable Materials Shape Granular Output 6-8t/H Application for Making Pellet and Mash Feed Cleaning Crushing-Mixing-Pelletizing-Cooling-Sieving Feed for Piglet Feed Transport Package Pallet Trademark Liangyou Origin Jiangsu China HS Code 84361000 Production Capacity 6-8tphProduct Description

6-8tph high quality piglet pellet feed production line with one pellet mill

Definition of high grade piglet feed

the feeding of piglet has a lot of to do with its growing performance, so high grade pig feed is a kind of high-end feed including creep feed, piglet feed for earlier stage of pig. The high grade piglet feed should be with good palatability and piglet's preference, good digestion and absorption without diarrhea, high nutrition and production rate which ensure the pig could grow rapid and steady after weaning.

Raw material:

maize, extruded maize, extruded soybean , extruded soybean meal,, fish meal, limestone , salt and etc.,

Process intro:

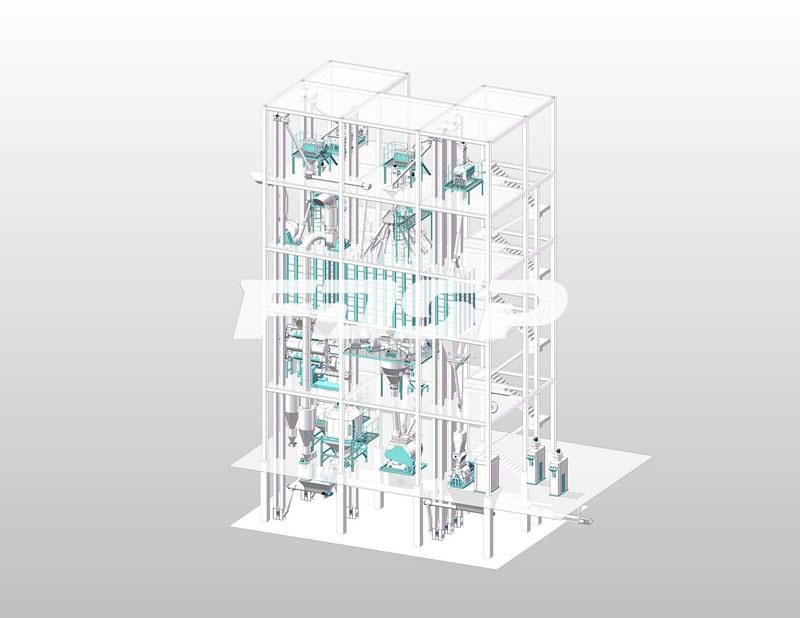

SZLH420 high grade piglet feed production line has followingcharacteristics: fine grinded particles(the hole diameter of screen should be 1-2mm), high requirement for curing (pellet mill adopt double conditioner or retainer), low conditioning temperature(adopt secondary pelletize in low temperature), small diameter for finished pellet (the diameter around 2-3mm). The most raw material are extruded(high curing for raw material), then grinded twice, mixed twice and pelletized twice in low temperature. The output for this SZLH420 high grade piglet feed production line is designed as output 6-8t/h, with single grinding line, one batching and mixing line, one expanding line, single pelleting line and a bagging line. the total power will be 725KW, production area dimension is : 19x17.5x29m, matching 1T boiler. SZLH420 high grade piglet feed production line is characterized by compact design and reasonable structure, and the satisfaction of environment protection requirements, meanwhile it can be directed to customers design.

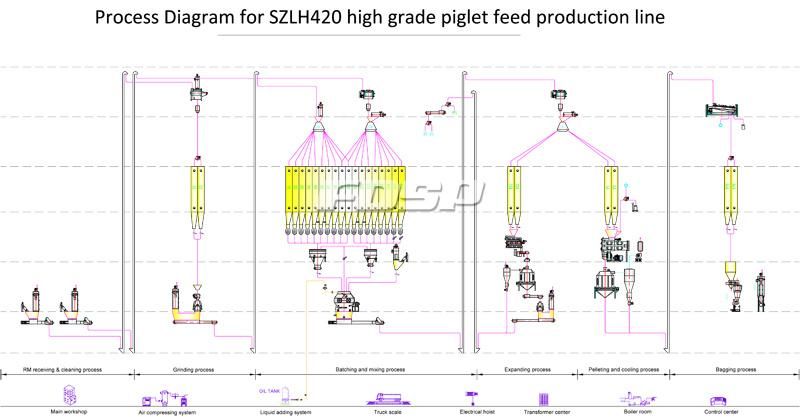

Technological process chart:

RM receiving and cleaning process--- grinding process--- batching and mixing process--expanding process--second grinding process--second mixing process--hypothermia pelleting process-bagging process

RM receiving and cleaning process:

Cleaning is playing a role to remove the impurities from raw material, including large impurities , nonmagnetic impurity like rope, clod and corn cob, and magnetic impurity like iron nails. It will ensure the quality of products and safety of following processing machine. the cleaning process for SZLH420 high grade piglet feed production line is including granule receiving cleaning and powder receiving cleaning.

cleaner: granule precleaner SCY80, output 20-30t/h, powder cleaner SQLZ60X50X100, output 10-15t/h

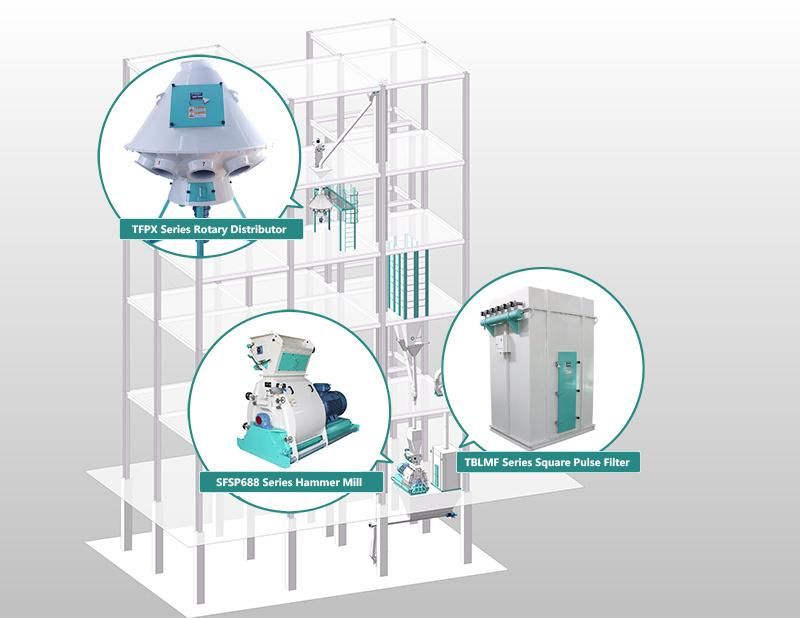

Grinding process:

The effect of grinding section is to increase the specific surface area of the feed, which is beneficial to the digestion and absorption for the animals, improving materials processing performance. As the high requirement for the fineness of grinded high grade pig feed material and the only hammer mill in grinding process of thisSZLH420 high grade piglet feed production line need to make both first grinding and second grinding, so the hammer mill with large power is adopted. two pre-grinding bin is set above the hammer mill. To make sure the safe running of hammer mill, the raw material should remove impurities through magnetic device. The cleaned material will go to the grinding bin for grinding. After grinding, the material will transported into bucket elevator by screw conveyor then go into the batching bins through distributor. when transported by screw conveyor, auxiliary suction system is also adopted to save energy consumption, prevent dust and reduce the material's temperature and improve the grinding efficiency.

grinding machine: hammer mill:SFSP668*1000,160KW, output 8-10t/h

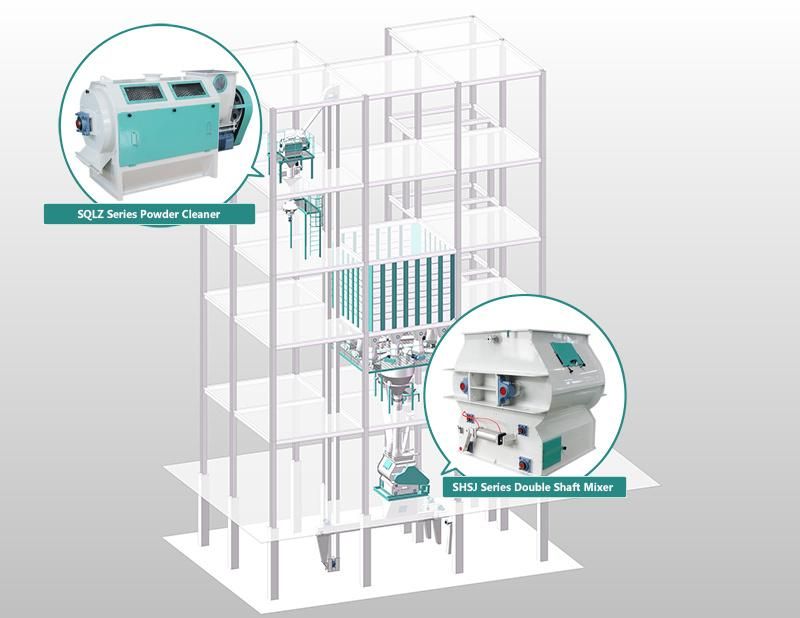

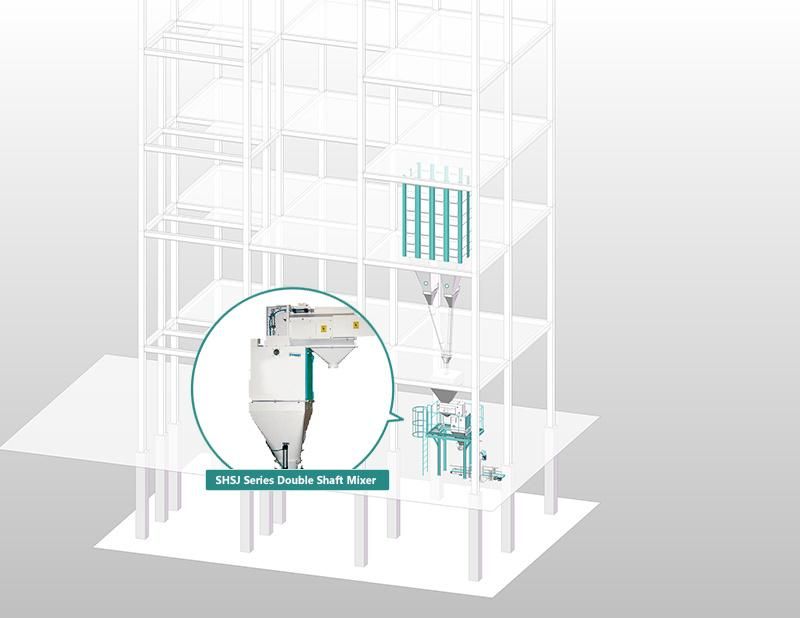

The batching and mixing process:

the batching process is a process to weigh kinds material accurately by specific device according to the different animal's formula to meet the nutritional requirement. Mixing is the process for kinds raw material for feed interblend each other to be in homogeneous distribution under the external force after batching . In the batching and mixing process of SZLH420 high grade piglet feed production line, two batching scale with 18 batching bins are used, the additives are manual added. The material are mixed in single mixer after batching then discharged by chain conveyor and bucket elevator.

Weighing machine: batching scale PCS10/PCS05, automatic weighing accuracy≤3‰.

mixing machine: mixer SHSJ2,18.5kw, 1000kg/P, output: 10-13t/h, homogeneityCV≤5%

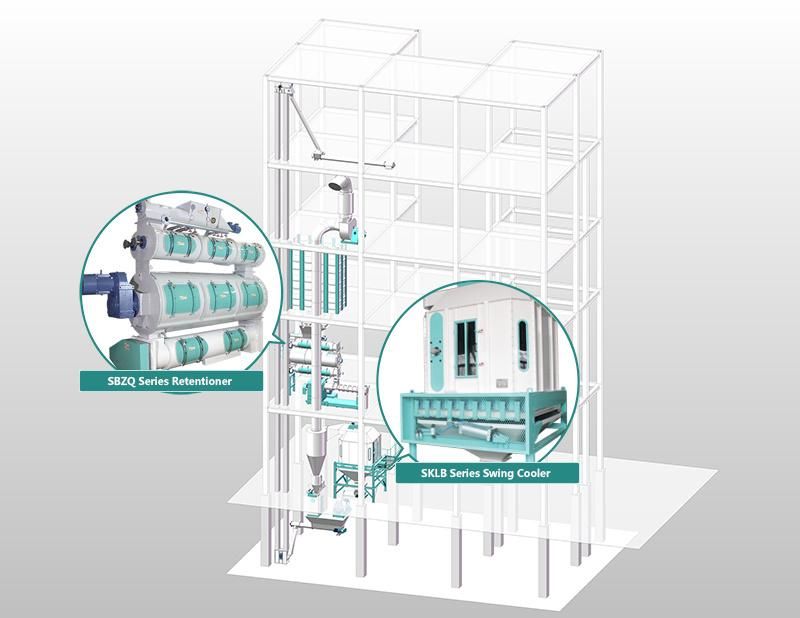

Expanding process:

the raw material will be extruded and expanded, add sensitive stock during second batching after expanding then make pellet under low temperature, all reduce the loss of sensitive elements. The expanded material as the formula are transported to batching bin by conveyor after cooling and second grinding. The largest advantage of this process is that it can keep most nutrition, less loss for sensitive stock. high starch gelatinization, high digestion after piglet's ingestion. easy to adjust the formula. improving the effectiveness of high grade piglet feed production and application.

expander: SPZS180,110KW, output:6-8t/h(batch feed)

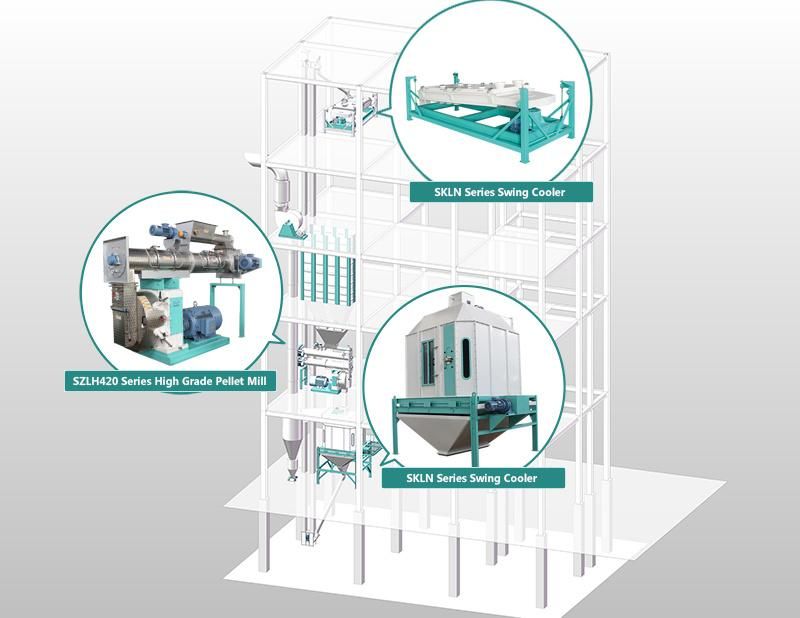

Pelleting Process:

the purpose of pelletize is to make use of the heat, moisture, and pressure in pelleting process to pelletize the feed which may be loose, easy to dust, with poor palatability and hard to transport, then the feed could be with better palatability, lower feed conversion rate, reduce feed waste and environmental pollution. In this process of 6-8tph SZLH420 high grade piglet feed production line, we use a double conditionerpellet mill, two pellet bins are set above the pellet mill. The finishedpellets will go to cooler(as there is no crumbled feed is pig feed so crumber is not needed), after that go into the rotary screener for shifting through bucket elevator , finally the finished product are packed into the bagging bins.

pelletize equipment: pellet mill SZLH420 with 110KW, output feed:6-8t/h. Cooling machine: SKLN6 with 1.1+1.5KW , volume 6m3, output 10-15T/H

Bagging process:

For the finished pellets or mesh feed in finished bins of SZLH420 high grade piglet feed production line, the part need to be packed will be bagged by automatic bagging scale, others will be transported by bulk trucks

Bagging machine: belt packing scale, capacity 20-50kg per bag, 6-8bag per minute.

Auxiliary system:

high grade piglet feed production line adopt dust collection system in bagging process to improve the working condition, oil adding system is usually added in mixing system to improve feed palatability.

Projecte Site

FAQ

1.How does your factory do regarding quality control?

Our factory has gained CE, ISO9001, SGS authentication.'Quality is priority'. We always pay great attention on quality controlling from the beginning to the end.

2.How long is your guarantee?

One year. After this period we will definitely support you when needed. You are welcome to contact us at any time.

3.Will you send engineers to install the plant?

Yes, we can send our engineers do the guide installation overseas.

4.Where is your company located? How can I get there?

Our company is located in Nanjing City, Jiangsu Province, China, near Shanghai.

If you arrived Nanjing Lukou International Airport, you can come to our company by Car about 30 Mins. Or you arrive Shanghai Hongqiao Airport, you can by train about 1.5H.

5. Where is your factory located? How can I visit there?

Our factory is located in Liyang City, Jiangsu Province, China, near Shanghai; and our International Business Centre is in Nanjing City. You can fly to Shanghai airport or Nanjing Airport directly. All our clients, from home or abroad, are warmly welcome to visit us!