2022 New Hot Sale CE ISO 15 T/H Concentrated Feed Production Line

Jiangsu Liangyou Zhengda Co., Ltd.- After-sales Service:Provided

- Type:Forage Equipment

- Processing Object:Animal-Derived Feed

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:With Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

Base Info

- Model NO.:Customize

- Pellet Mill Type:Ring Die Pelleter

- Bulking Machine Type:Twin Screw Bulking Machine

- Expanding Method:Wet Expansion

- Condition:New

- Applicable Materials Shape:Granular

- Warranty:1 Year

- Transport Package:Pallet

- Specification:2000KG

- Trademark:FDSP

- Origin:China

- HS Code:8438800000

- Production Capacity:3-20t,H

Description

Basic Info.

Model NO. Customize Pellet Mill Type Ring Die Pelleter Bulking Machine Type Twin Screw Bulking Machine Expanding Method Wet Expansion Condition New Applicable Materials Shape Granular Warranty 1 Year Transport Package Pallet Specification 2000KG Trademark FDSP Origin China HS Code 8438800000 Production Capacity 3-20t/HProduct Description

2022 New Hot Sale CE ISO 15 T/H Concentrated Feed Production LineConcentrated feed is made by protein feed, additive premix and mineral feed in a certain proportion, it is the middle product of full price feed, i.e. semi-finished feed which can't be fed directly to animals. This feed can reduce the transport of energy feed and it is convenient to use, it can solve the shortage of protein feed of general farmers.

Jiangsu Liangyou Zhengda Co., Ltd., specializing in the production of feed machinery and engineering, can provide customers with complete sets of equipment solutions for livestock feed (pig, etc.), poultry feed (chicken, duck, goose,etc.), ruminant feed (cattle, sheep, etc.), common aquatic feed (four major Chinese carps, etc.), special aquatic feed (shrimp, crab, etc.), extruded aquatic feed (floating and sink fish feed, shrimp feed, etc.), premix feed (including all kinds of additives, etc.), and pet food(cat food, dog food, etc.). to meet the different needs of customers.

Now take the 15 t/h concentrate feed production line as a case, according to the process flow and each section to do the following introduction and description.

Raw materials:

Common ingredients contain soybean meal, bran, cottonseed meal, wheat flour, fish meal and various essential amino acids, vitamins and inorganic salts

Process flow diagram introduction:

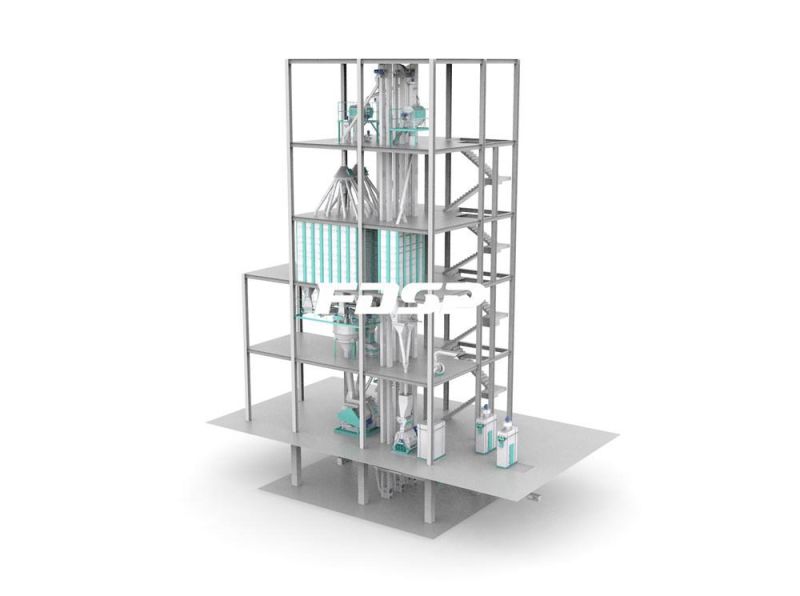

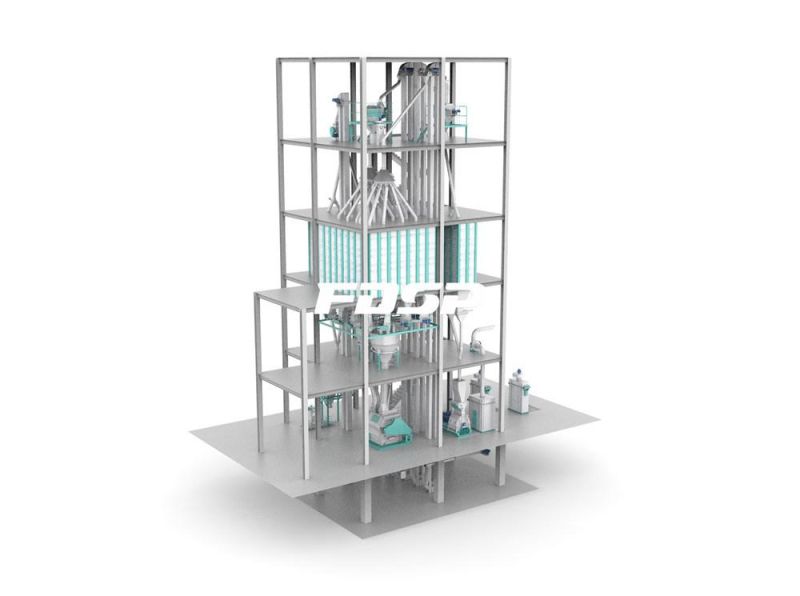

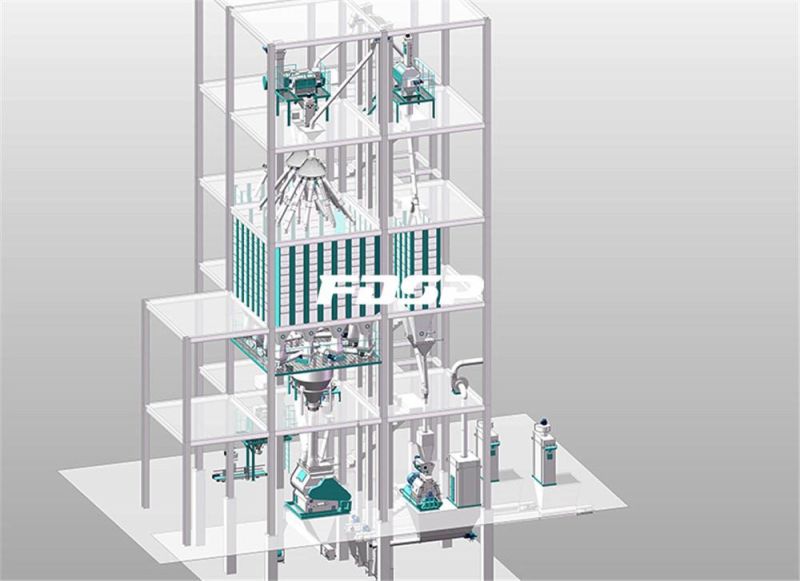

The processing characteristic of the concentrated feed line is that it does not contain the pelleting section and reduce the grading of the mixing of the mixture as far as possible, direct packing. The concentration production line is designed to produce feed with 15tph capacity, using single crushing section, single batching & mixing section and finished packing section. The total power of the equipment is about 230KW.The construction area of the production area is about 10x11x24m. The whole line of the 15T concentrated feed line is compact in design, reasonable in structure, meeting the requirement of environmental protection, and can be customized designed according to the requirements of customers.

Process diagram:

Raw materials receiving and cleaning section --Grinding section --Batching and mixing section--Packing section

Raw materials receiving and cleaning section:

In this section, pellet feeding cleaning and powder feeding cleaning are separated independently and separate dust removal. Dust removal effect is good.

Cleaning equipment:granules sifter SCY80,capacity 20-30 T/H;powder sifter SQLZ60X50X100, capacity 10-15 T/H.

Grinding section:

This section adopts one hammer mill, and with two pre-grinding bins.

The crushed varieties can be changed alternately. Before entering the bins, the impurities are removed by magnetic separation device to ensure the safe operation of the hammer mill.

Grinding equipment : Hammer mill SFSP668×800, 110 kw, designed to produce 10-15 t /h

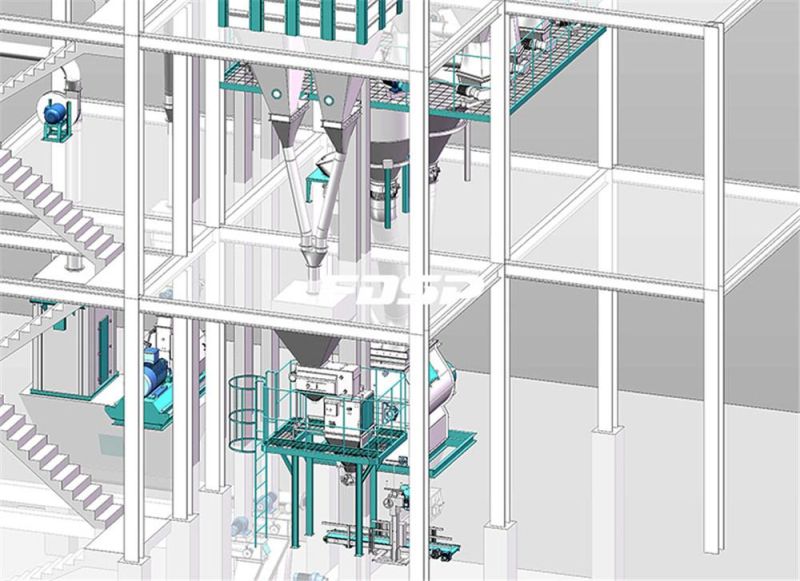

Mixing section:

This section adopts 16 batching bins, two sets of batching systems simultaneously batching. It is controlled by the batching program independently developed by our company to realize accurate fast and slow feeding, fast batching and high precision.

Weighing equipment: Dosing scale PCS10/PCS05, dosing precision: dynamic ≤3‰, static ≤1‰.

Mixing equipment: mixer SHSJ2, (18.5 KW, 1000 kg/ batch), designed to produce10-15 t/h. Mixture uniformity CV ≤5%.

Packing section:

There are 2 finished product bins in this section,which are specially designed for storing powder materials. The special anti-grading device is designed in the bin to effectively prevent material grading and knot. Finally, the packaging scale will carry out automatic weighing and packing.

Packing equipment: Screw scale(Specially for powder feed), packing range: 20-50 kg/ bag, 4-6 bags/minute.

Auxiliary section:

Dust removal system to improve workers' working environment; Grease adding system, common mixer place added to improve feed palatability.

According to the needs of different customers, the scheme can be optimized:

1. The scheme adopts the single-point dust removal mode, that is, each rotary distributor (powder material) and pellet cleaner is equipped with a pulse dust filter, which has a good dust removal effect. Single point of dust removal is our company's humanized design, which can provide a better working environment, but the cost increases. Customers can consider whether to use this configuration according to the actual needs;

2. The quantity of bins can also be adjusted according to the formula of customers, the characteristics of raw materials and other factors, so as to achieve the highest utilization rate and effectively control the production cost;

3. Assembly or welding can also be adopted for the installation of the bin. The assembly bin has a high cost, quick and convenient on-site installation, and the welding silo has a low cost. On-site welding by workers is with high labor intensity and long time. Users can make reasonable choices according to their own needs;