Chicken Egg Incubator Hatcher Machine Duck Incubator for Sale

INGFE International (GZ)Co., Ltd- Type:Small Hatching Machine

- Usage:Incubation Equipment

- Application:Chicken

- Power Source:Electric

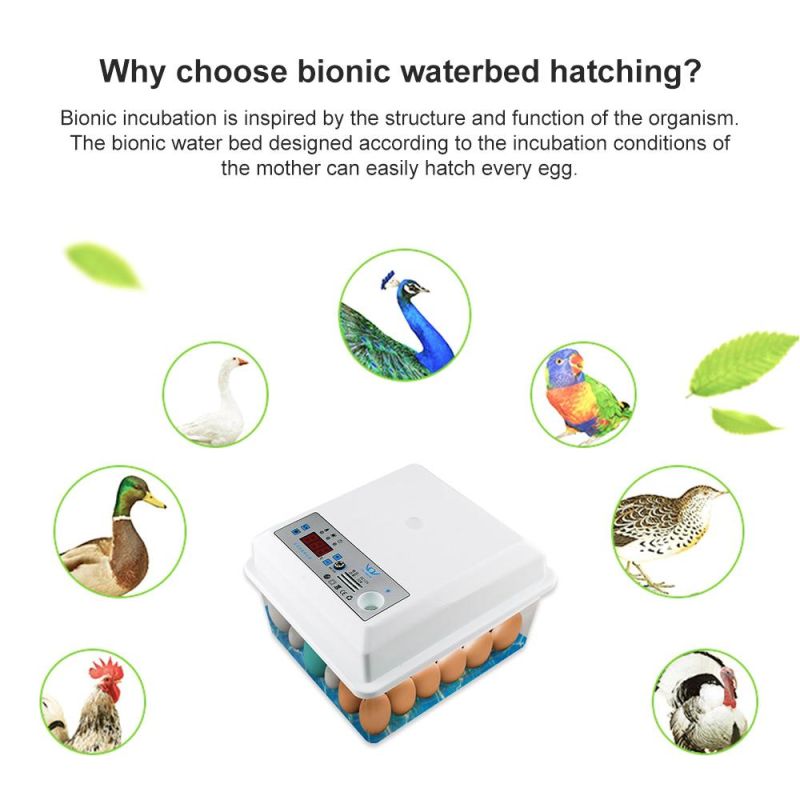

- Heating and Ventilation Equipment Type:Steam or Hot Water Heating

- Epidemic Prevention Equipment:Medicated Bath Equipment

Base Info

- Model NO.:IN-EG20

- Blade Type:Straight Teeth

- Computerized:Non-Computerized

- Certification:ISO9001:2008, CE

- Condition:New

- Warranty:6 Month

- Transport Package:Cartoon

- Specification:21.5*21.5*19.2CM

- Origin:China

- HS Code:3926909090

- Production Capacity:100000 PCS One Month

Description

Basic Info.

Model NO. IN-EG20 Blade Type Straight Teeth Computerized Non-Computerized Certification ISO9001:2008, CE Condition New Warranty 6 Month Transport Package Cartoon Specification 21.5*21.5*19.2CM Origin China HS Code 3926909090 Production Capacity 100000 PCS One MonthProduct Description

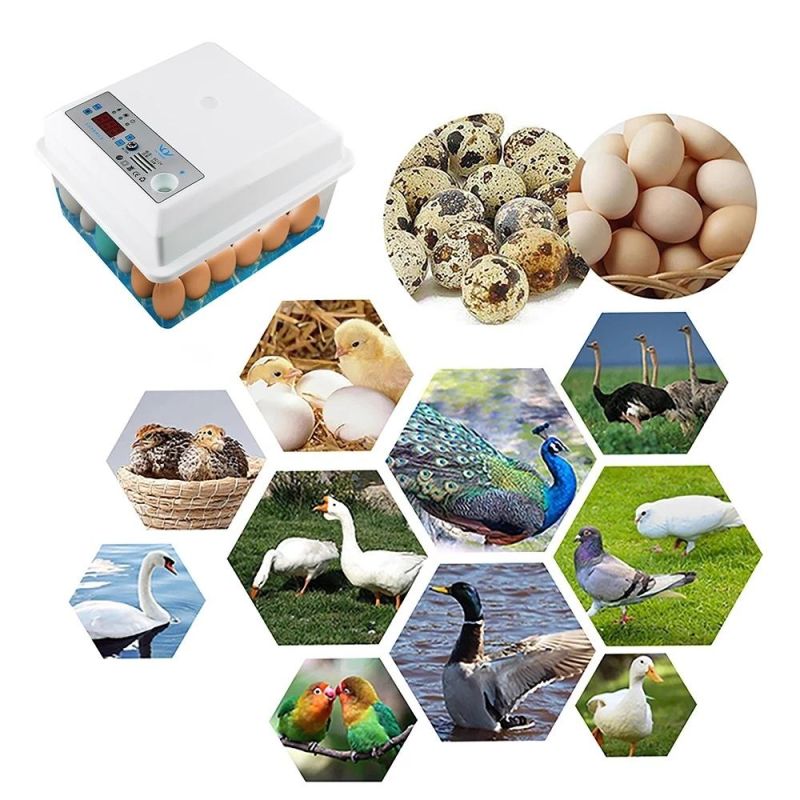

chicken egg incubator hatcher machine duck incubator for sale

Description:

1. 100% brand new and high-quality products.

2. Made of high-quality materials, durable and practical.

3. The temperature difference of the machine can be calibrated according to the measured temperature, so that the temperature is more accurate and the shell rate is higher.

4. Double power supply, not afraid of power failure.

5. Bionic incubation, inspired by the structure and function of the organism, the bionic water bed designed according to the incubation conditions of the mother can easily hatch every egg.

6. Accurate temperature control, self-contained photo eggs, not afraid of power outages, low energy consumption

Parameter:

Product voltage: AC110V-220V/DC12V

Power: 20W

Size: 36*24*19cm

Plug: American plug

Scope of application: all kinds of poultry eggs

Instructions:

Step 1: First add proper amount of water to the hatching water bag, ready to use.

Step 2: After receiving the incubator, lay the bottom heating pad flat. Place a water bag filled with water on the heating pad. The opening of the water bag is fixed in the foam box next to the incubator with a clip to prevent water from splashing out.

Step 3: Put the temperature sensor into the water bag and fix it with tape (it must be attached to the surface of the water bag and contact with the water bag). When you are ready, put the eggs.

Step 4: Start the test machine. After the temperature stabilizes, put the sterilized eggs evenly into the water bag in the incubator.

Step 5: In the incubator, after the hatched eggs are laid, cover the eggs with a breathable and warm quilt. It will not be too loose or too tight. The hatching process does not need to cover the lid of the incubator. If the temperature is low, cover the quilt tightly ; If the temperature is high, do not cover it too tightly.

Step 6: Fill the watering can with water, put it into the machine, and keep the water temperature in the kettle consistent with the temperature of the eggs. Spray water three days before hatching, spray 2-3 times a day.

Our Advantages:1.The company has more than 10years of experience in the temperature control industry. All our products have passed the European Union CE certification, the United States FCC certification, and have design patents and utility model patents.Products are exported to more than 100 countries around the world, supporting various OEM customization requirements.

2. The company has its own product research and development center, production base and shipping warehouse.The production base is near Guangzhou ports, with short transportation time and low cost.

3.We conduct 100% QC testing and inspection on the products before they leave the factory to ensure good product quality.

4.We willchoose the best and safe packaging materials to ensure that your order will not be damaged during transportation.

5.Sales provide good pre-sale service and one-to-one after-sales service with professional engineers.

6.Provide free product or packaging design, assist customers in developing new products, and provide product technical guidance.