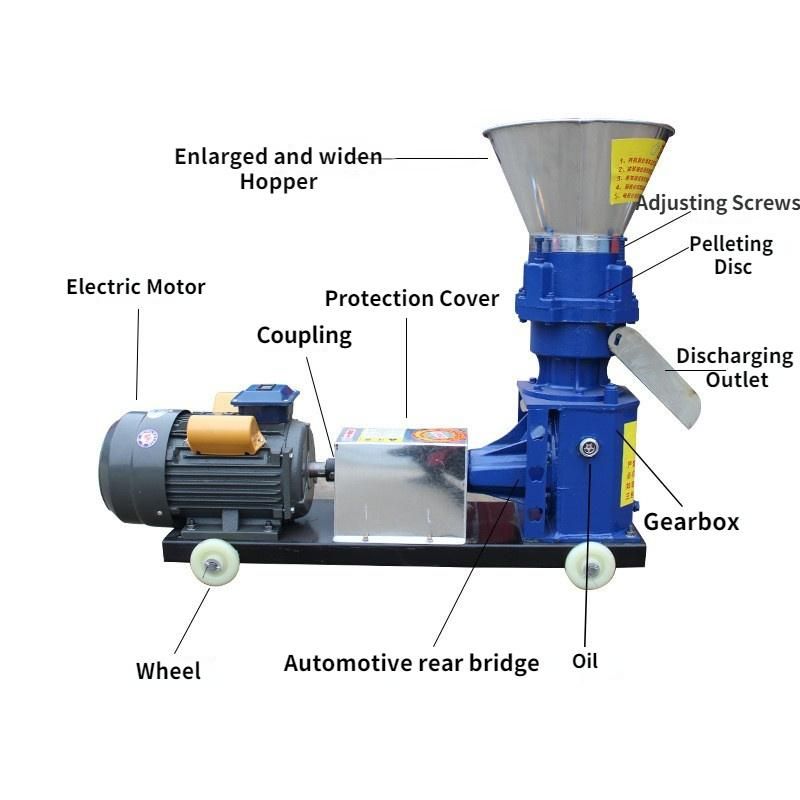

Farm Animal Pet Food Making Extruder Floating Fish Feed Pellet Machine Household Pelletizing Machine Pelitzadora

Hunan Dongfanghong Electromechanical Manufacturing Co., Ltd.- After-sales Service:24,7

- Type:Forage Equipment

- Processing Object:Animal-Derived Feed

- Processing Technics:Mixing-before-Crushing

- Screen Mesh:Flat Die

- Grinding Equipment Type:Roll Crusher

Base Info

- Model NO.:160T

- Pellet Mill Type:Screw Granulator

- Bulking Machine Type:Sigle Screw Bulking Machine

- Condition:New

- Warranty:1 Year

- Model:125,150,210,260,300,400

- Output Capacity:40kg,H~2000kg,H

- Applicable Raw Materials:Wheat,Maize,Corn,Paddy,Rice,Grass,Straw,Wood etc..

- Driven Engine:Electric Motor, Diesel Engine, or Gasoline Engine

- Main Market:All World

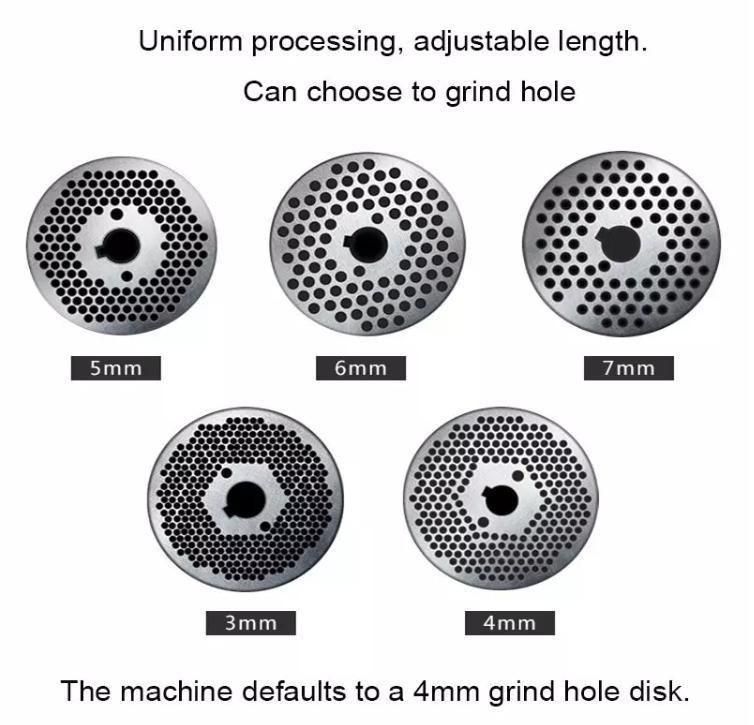

- Pelleting Disc Size:2mm,2.5mm,3mm,4mm,5mm,6mm

- Machine Raw Material:High Quality Steel

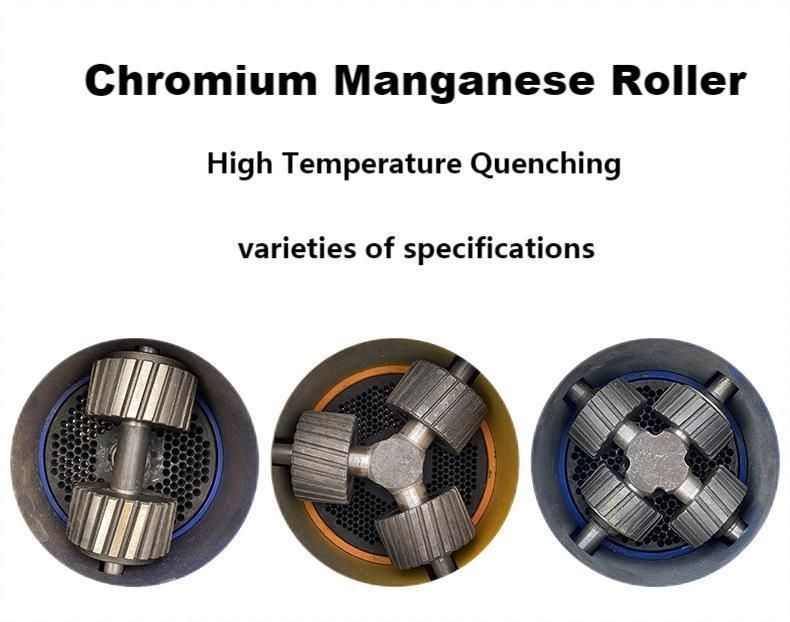

- Rollers Quantity:2,3,4

- Matched Electric Motor Power:3.0kw~30.0kw

- Matched Diesel Engine:8.0HP~110HP

- Voltage:220V,380V,Customized

- Pakeage Size:810*320*515mm

- Certification:CE,ISO

- Transport Package:Plywood Case

- Specification:630*270*750mm

- Trademark:Dongfanghong

- Origin:Hunan

- HS Code:8436100000

- Production Capacity:30000,Year

Description

How to make your own pellets with our A small production less expensive for bamboo chicken feed granulator

The complete pellet making production line is composed the following steps.

Step1:Crushing

1) Before raw materials are made into biomass pellets of pellet machine, they are firstly reduced into smaller, uniform- sized particles. When the thickness is larger than 6 mm or size is greater than 50*50 mm, a pellet machine is needed to chip these materials into smaller pieces.

Step2:Drying

2) After all the raw material of pellet machine are crushed, dryer will be needed since for the most raw materials have the moisture content of about 50%.However, in general the optimal moisture content for pelletiztion is 10%-15%. Therefore, a rotary dryer is included in the pellet machine to reduce the moisture content.

Step3:Pelletizing

3) After crushing and drying all the raw materials properly, it is ready for the pellet machine. The pellet machine or press is the key piece of machine in the pellet plant. Pellet machine should be mentioned that impurities for the raw materials just like metal or stone, may damage the die and rollers of pellet machine.

Step4:Cooling

4) Usually after pelletizing, the temperature of pellet can reach almost 60-80 degrees, and also the moisture content is close to 15%. For storage purposes, a cooler must be used to reduce the surface temperature and moisture content.

Pellet Machine Advantages:

1. Simple structure, easy to clean and maintain;

2. Spare parts are easy to change, less cost for rollers and dies;

3. Simple operating, just 1 worker is OK;

4. Be able to change new die and rollers faster to save time to produce pellets;

5. Small and light weight, which can be used in home, small farm and light industrial field.

Our Services

Pre-sale service

1.Keep 24 hours online to answer customer's inquiry and online message.

2.According to customer's requirement,guide customer choose the best suitable model.

3.Offer detailed machine specification,pictures and best factory price.

After-sale service

1.Detailed English User Manual will be equiped with the machine.

2.Broken parts of the quality problem(except the wearing parts) will be sent free.

3.Timely respond to customer's technical problem.

4.New products update for customer reference.

FAQ

Q1: What is the MOQ for your Animal Feed Pellet Machine?

A: Our MOQ is 1 set. And any order quantities are highly appreciated.

Q2: Can I get a free sample of your Animal Feed Pellet Machine?

A: Yes, surely, we would like to provide the sample for you. But, we are afraid that you will pay for the sample and delivery cost.

Q3: What is your guarantee period for your Animal Feed Pellet Machine?

A: Our Animal Feed Pellet Machine guarantee period is 12 months, and we also provide 24 hours on-line service if any problems happen.

Q4: Do you accept OEM & ODM?

A: Yes, OEM & ODM projects are available. You are warmly weclome to have your own color, logo, company name, contacts and any design on the Animal Feed Pellet Machine. Even we are willing to design the color, logo, packages for you.

Q5: Can I test your Animal Feed Pellet Machine with the raw material when visiting your factory?

A: Yes, surely, any testing our Animal Feed Pellet Machine with the raw material is highly appreciated.