Aquaculture Cage Buoy Fish Farm Cage Buoy Cage Mooring Buoy EVA Foamed Buoy

Qingdao Waysail Ocean Technology Co., Ltd.- After-sales Service:Yes

- Type:Cage Buoy

- Working Method:Floating

- Certification:CE, ISO9001:2008

- Net Buoyancy:1200kg

- Foam Corn:EVA Foam

Base Info

- Model NO.:1200kg Buoyancy

- Skin:Polyurethane Skin

- Fittings:Swivel Eyes

- Color:Yellow,Orange

- Swl:1500kgs

- Package:Wooden Packing

- Application:Mooring

- Industry:Marine and Aquaculture

- Specification:1200kg

- Origin:China

- HS Code:39269090

- Production Capacity:150PCS,Week

Description

Basic Info.

Model NO. 1200kg Buoyancy Skin Polyurethane Skin Fittings Swivel Eyes Color Yellow/Orange Swl 1500kgs Package Wooden Packing Application Mooring Industry Marine and Aquaculture Specification 1200kg Origin China HS Code 39269090 Production Capacity 150PCS/WeekProduct Description

Mooring Buoys---OEM & ODM---

Waysail rotational moulding plastic mooring buoys filled with closed cell EPS foam, buoy shell made by marine corrosion resistant polyethylene, around a central tubular steel frame, forming a high quality moooring buoy with excellent performance and lower cost. Our mooring buoys are rapidly replacing the traditional steel mooring buoys. This is due to their low maintenance costs, excellent waterproofing, impact resistance, long service life, easy construction, easy to handle and repair.

Strong, foam filled and unsinkable buoys, particularly well suitable for mooring fish cages and other aquaculture applications. The buoys are fitted with a high quality galvanized steel rod and swivel.

Material Specifications:

Outer Shell: Rotational Moulded Polyethylene Thickness 9-10mm

Foam: Expanded Polystyrene(EPS).

Stell Structure: Inserts are made with a stainless steel, Internal components are also stainless steel or hot-dipped galvanized.

Colour: Yellow/orange

Features & Benefits:

Highest quality UV stabilized seamless one-piece construction with uniform wall thickness ensures a robust life expectancy to 15+ years.

Large diameter load plates secured to the shell for maximum load disbursement.

Refined EPS foaming process with over 20 years of experience significantly reduced risk of sinking and environmental contamination.

Swivel eyes prevent twisting and moderate strain on the tackle.

Indented area for retro-reflective tape inhibits sliding and loss of reflective material.

Product Exhibition:

Application:

Applications including but not limited to:

Offshore vessel mooring

Remote mooring of vessel

Fish Farming Cage Support

Additional mooring support for large vessel

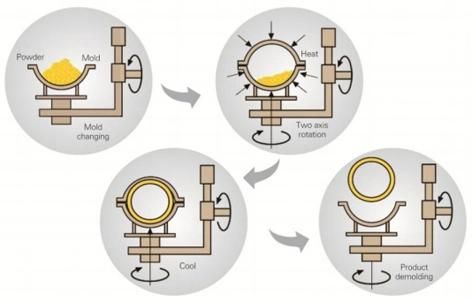

Manufacturing Technique:

Rotational moulding is a process of forming hollow plastic products. Firstly put the plastic power into the moldand then heated and rotated along two vertical axes. The powder in the mold is melted and adhered onto the mold inner surface, then cooling down the mold and take out the product when it reaches a correct temperature.

Compare to the extrusion, injuection and blow molding processes, which are often used in plastic molding. The rotatinal moulding process is more suitable for the production of large, medium or complext plastic products. The products have almost no internal stress to ensure a very long service life.

Due to the long production time and high energy consumption, rotational moulding process has special requiremen for the performance of raw materials. After many years of test and demonstration on the flow rate of raw material solution, resin density and thermal stability of resion, we have selected 100% suitable raw materials for plastic buoys, and estalished a stable supplier channel. This will ensures the high quality and stability of our products.

Our company promises that 100% of our products use original raw materials, all the waste materials produced in the production process will be destroyed through formal channels or resold to the recycling middleman.