Wood Working Machinery 20t/H Wood Logs Wood Pellet Biomass Plant

Jiangsu Liangyou Zhengda Co., Ltd.- After-sales Service:Engineer Available

- Warranty:1 Year

- Structure:Horizontal

- Fuel Size:Particle

- Output (T/H):20

- Power (Kw):5027

Base Info

- Model NO.:FDSP series

- Main Machine:Hammer Mill, Pellet Mill

- Storage:Yes

- Process Design:Free

- Installation Service:Included

- Transport Package:Pallet

- Specification:CE, ISO, SGS

- Trademark:Liangyou

- Origin:Jiangsu China

- HS Code:8436800000

- Production Capacity:1 Sets,Month

Description

Basic Info.

Model NO. FDSP series Main Machine Hammer Mill, Pellet Mill Storage Yes Process Design Free Installation Service Included Transport Package Pallet Specification CE, ISO, SGS Trademark Liangyou Origin Jiangsu China HS Code 8436800000 Production Capacity 1 Sets/MonthProduct Description

Wood working machinery 20T/H wood logs processing linewood pellet biomass plant

Jiangsu Liangyou Zhengda Co., Ltd. specializes in the production of complete biomass pellet fuel forming equipment, can provide customers with logs, wood chips, shavings and other raw materials of biomass pellet production line; Biomass granulation production line with building template, woodworking scrap and other raw materials; Complete biomass pelleting production line with corn straw, wheat straw and straw grass as raw materials; Complete biomass pelleting production line with fruit shell, fruit residue and palm as raw materials; Complete biomass pelleting production line with crop waste, sludge, coal and other raw materials, tailor-made complete equipment solutions for customers, to meet the different needs of customers.

Now take the construction wood logs pellet production line project of 20tph as a case, according to the technological process and each section to do the following introduction and description.

Definition of wood logs pellet production line

Using logs as raw materials, formed by solidifying and extruding into high-density pellet fuel through pretreatment and processing.

There are mainly logs of pines, firs, acacia trees, beech trees,eucalyptus trees and other trees.

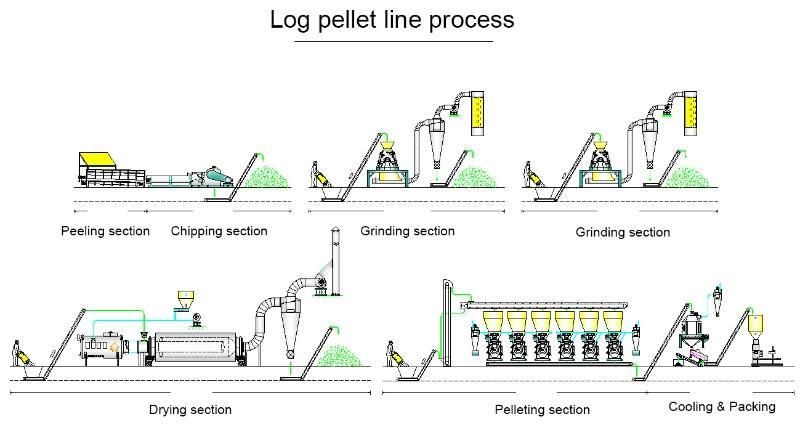

Introduction to flow diagram:

After debarking the branches and trunks of logs, the logs are cut into small chips by the chipper. The size of the chips is 20-30mm and the thickness is 5-10mm, then be fine grinded into sawdust of 3-4mm by the hammer mill; next the raw material with 40% moisture is dried to about 15% through a three-layer drum dryer; finally is pelleted, the diameter of finished pellets is 6-10mm for choosing.After pelleting and cooling, it is packed into 20-50kg/ bag by small bag packing scale for convenient transportation and sale. The capacity of log pellet complete project is 17.5-22.5tph biomass pellets line, the total power of whole line equipment is about 5027 kw, and the plant covers an area of 10,000 m2, including raw material storage and finished product storage. The whole line's design is compact, the structure is reasonable,meets the requirements of environmental protection, and can be directed designed according to customers' requirements.

Flow Diagram:

Debarking Process---Chipping Process--Coarse grinding Process--screening process--Drying Process--Fine Grinding--Pelleting Process--Storage Process

Craft features and process introduction

Debarking Process:Raw material debarking can improve heat value of finished pellets, reduce ash residue after combustion of finished pellets and reduce emissions.

Debarking Machine(4sets): LYBP760/11, power is 45kw, designed capacity is 30m3.

Chipping Process:The chipping process of the log pellet complete project is to process the wood logs into wood chips, the size is 20-30mm, the thickness is about 5-10mm, and then enter the processing of the following sections.

Chipping Machine(4sets): Chipper LYGX218D, power of main motor is 132kw, feeding roller is 4kw, oil pump is 0.55kw, designed capacity is 38m³/set.

Grinding process: 20*20 square screen is adopted to do the first coarse grinding and then to do the drying.

Grinding equipment(4sets): MFSP68*120,power 200kw,capacity: 9-10T/H( raw material moisture 40%)

Cleaning equipment(3sets): MCY160*300, power: 3kw. Designed output:5-8t

Drying section: three-layer drum dryer, after drying, sawdust moisture in about 13-18%.

Drying equipment(4sets): LYHG50, drum diameter 3.0m, length 11.6m, power 19kw, design yield 5T/set, (before drying raw material moisture is 40%).

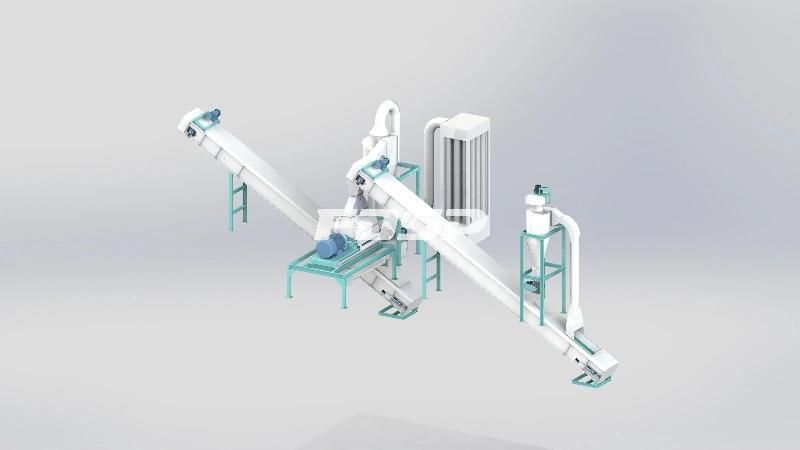

Fine grinding process: The grinding work has no dust discharge. After grinding, the sawdust will be transported through pneumatic transmission by the fan suction air pressure. The hammer mill is a water droplet type structure; the hammer mill rotor can be operated in forward and reverse directions to improve the service life of the hammer blade; the direct transmission mode of the motor is adopted.

Grinding equipment(4sets): MFSP68*120,power 160kw,capacity: 6-8T/H( raw material moisture 15%)

Granulation process:The diameter of biomass pellet is optional from 6-10mm, and the biomass pellets have the characteristics of high calorific value, no pollution and low ash content, which can be widely used in biomass power plants, biomass steam boilers, household fireplaces, drying furnaces and biomass gasifier.

Pellet mill(8sets): WZLH680, main motorpower: 185kw, power of forced feeder: 1.5kw, design with 2.2-2.8T/set output.

Cooling machine: MKLB6, the volume of the cooling chamber is 6m³, and the designed capacity is 8-12 tons per hour.

Storage process: 2000T finished pellet storage silo is adopted, the finished pellet products can be stored into the silo and for bulk shipment.

Highlights and optimization of the scheme design:

1. In this scheme, wet materials in the front section are piled up in a yard (less dust from wet sawdust), while dry materials in the back section are stored in the silo (more dust from dry sawdust), which can effectively control dust pollution in the workshop and save costs.

2. As the client of the project requires the finished product pellets to be shipped in bulk, it can be adjusted into various forms of packaging equipment according to the client's requirements on the finished product packaging.

Detail Quotation Solutions for you, we need to know Information as Follows:

(We can make the biomass pelleting project solution according to customers' actual specifictions,such as raw material,size of material,moisture of material,capacity,packing method etc.)

(1). What capacity would your prefer?

-----The Capacity Range of Wood Pellet Machine: 0.8-1T; 1.5-2T; 2-3T;3-4T.

(2).What is your raw material?

-----According to different raw material(such as hard wood,soft wood,straw,rice hust), capacity is different.

(3).What is your raw material size?

-----Best size for pressing high quality pellets is 3mm-5mm.

(4).What is the moisture of your raw material?

-----Better to be 10-15%.( If large than this, then we will recommend your Dryer Machine)

(5).Final Pellets Size?

-----We have Diameter for Pellets:6mm, 8mm, 10mm, 12mm, (Different Diameters for your Different Requirement.)

------Pellets Length: Adjustable20-50mm. (Normally our clients ask pellets length of 33mm, between 30-36mm)

About FDSP

six reasons to choose us

Professional Design, personalized customization

Comb your needs accurately

Create FDSP turnkey boutique engineering

Make field work, adjust measures to local conditions

Professional staff go deep into the construction site

Scientific and reasonable, economic and practical, meet environmental protection

Professional team, professional installation

With 25 years of actual experience we have a a professional technical team for Design, manufacture and installation

Technical guidance, full escort

In strict order to ensure the highest efficiency

to provide professional, targeted services

Professional services, worry-free production

Truly "customer-centric"

To provide excellent service to our customers

Quick response, life-long maintenance

There is no best. There is only more than best

to pursue the never-ending improvement for products

Certification

We have passed certification of ISO9001:2008,CE,Gost-R,SGS,ETC.

Exported Area

We have built business relationship with customers from more than 30 countries and region in SEA, Middle East ,Africa ,Europe ,Oceania and South America.

Welcome to contact us freely!