Low Price Poultry Feed Processing Equipment Sale

ZHENGZHOU YUFENG HEAVY MACHINERY CO., LTD.- Type:Feed Mill Plant

- Processing Object:Mixed Feed

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:With Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

- Pellet Mill Type:Ring Die Pelleter

Base Info

- Model NO.:1-18 T,H

- Expanding Method:Wet Expansion

- Condition:New

- Applicable Materials Shape:Powder

- Warranty:One Year

- Name:Feed Pellet Production Line

- Capacity:1-18 T,H

- Power:According to The Capacity

- Application:Making Feed Pellets for Poultry

- Pellet Formation Rate:Over 95%

- Transport Package:Standard International Export Packing.

- Specification:According to the capacity

- Trademark:YUFCHINA

- Origin:Henan, China (Mainland)

- HS Code:8436100000

- Production Capacity:1 Set,Sets Per Month

Description

Basic Info.

Model NO. 1-18 T/H Expanding Method Wet Expansion Condition New Applicable Materials Shape Powder Warranty One Year Name Feed Pellet Production Line Capacity 1-18 T/H Power According to The Capacity Application Making Feed Pellets for Poultry Pellet Formation Rate Over 95% Transport Package Standard International Export Packing. Specification According to the capacity Trademark YUFCHINA Origin Henan, China (Mainland) HS Code 8436100000 Production Capacity 1 Set/Sets Per MonthProduct Description

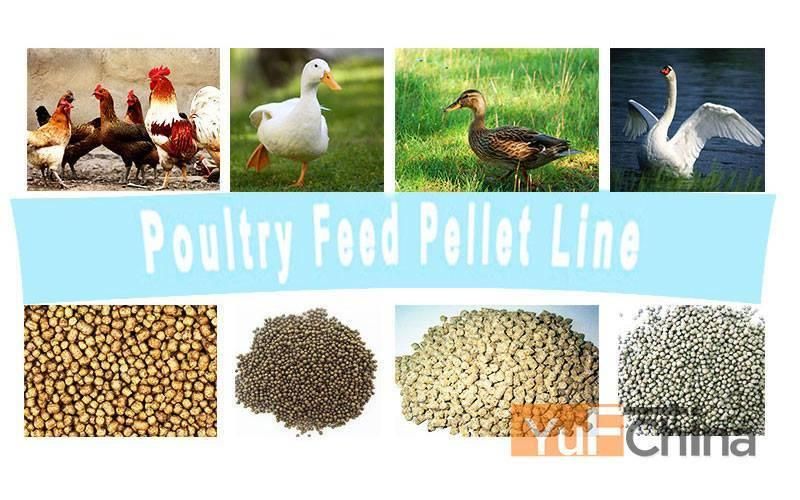

Low price poultry feed processing equipment sale

Introduction of feed production line

The feed pellet production line can be used to make feed pellets for poultry and domestic animals. It is also suitable for straw feed granulator, rice husk feed granulator, corn feed granulator, grass meal feed granulator. It can be widely used in medium and small aquaculture, grain and feed processing plants, livestock farms, poultry farms and individual farmers.

Benefits of feeding animals with pellet feed:

1.Can avoid animal picky food. Formulated feed formula has a variety of raw materials, comprehensive nutrition, can prevent animals from choosing their favorite from the powder. Due to the uniformity of grain feed during storage and feeding, the loss of feeding can be reduced by 8%-10%.

2.In the process of pelletizing, some physicochemical reactions occurred in feed due to the comprehensive action of moisture, temperature and pressure. It can make feeding animals digest feed more effectively and turn it into weight gain.

3.Storage and transportation are more economical.

4.Good liquidity and easy management.

5.Avoid automatic grading of feed ingredients and reduce environmental pollution.

6.Granulated feed after high temperature conditioning and granulation can kill salmonella in animal feed.

Process of Feed Production Lines

Raw materials---Crushing---mixing---granulating---cooling---crushing---grading---

quantitative packaging.

Related machines introduction:

Mixer:

Mixing the powder feed raw material according to the formula. And the formulated feed formula has a variety of raw materials, comprehensive nutrition.

Pellet machine:

Pressing the powder feed into pellet. This feed pellet machine is suitable for different kind of poultry feed pellet and domestic animal feed pellets.

| Model | Main Power (kw) | Capacity (t/h) |

| SZLH250 | 15 | 0.5-1.5 |

| SZLH320 | 37 | 1-5 |

| SZLH350 | 55 | 2-7 |

| SZLH420 | 110 | 3-12 |

| SZLH508 | 132/160 | 5-18 |

Counterflow type cooler:

This cooling machine is used to cooled down the pellets to the room temperature, which make them easy to store.

Pulse dust collector:

Used to collect the dust and the materials.

Contact Information of poultry feed plant

We can design machines according to customers' need.If you want to learn more information,please contact us at any time.