Twin Screw Fish Feed Equipment Price

Jinan Datong Machinery Co., Ltd.- Type:Pellet Mill

- Processing Object:Cereals

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:Without Screen Mesh

- Grinding Equipment Type:Roll Crusher

- Pellet Mill Type:Screw Granulator

Base Info

- Model NO.:SLG

- Bulking Machine Type:Twin Screw Bulking Machine

- Expanding Method:Wet Expansion

- Condition:New

- Applicable Materials Shape:Powder

- Material:Stainless Steel

- Line Size:50*5.*6.0

- Motor Brand:Siemens Brand China Brand

- Inverter:Delta Brand

- Fish Food Types:Floating Types

- Electric Parts:LG, FUJI, Omron etc

- Capcity:500kg,H Semi Auto Feeding Floating Fish Feed Pelle

- Name:Fish Feed Mill Machine

- Transport Package:Woodcase

- Trademark:Jinan Datong Machinery Company

- Origin:Jinan

- HS Code:843880000

- Production Capacity:500kg,H

Description

Basic Info.

Model NO. SLG Bulking Machine Type Twin Screw Bulking Machine Expanding Method Wet Expansion Condition New Applicable Materials Shape Powder Material Stainless Steel Line Size 50*5.*6.0 Motor Brand Siemens Brand China Brand Inverter Delta Brand Fish Food Types Floating Types Electric Parts LG, FUJI, Omron etc Capcity 500kg/H Semi Auto Feeding Floating Fish Feed Pelle Name Fish Feed Mill Machine Transport Package Woodcase Trademark Jinan Datong Machinery Company Origin Jinan HS Code 843880000 Production Capacity 500kg/HProduct Description

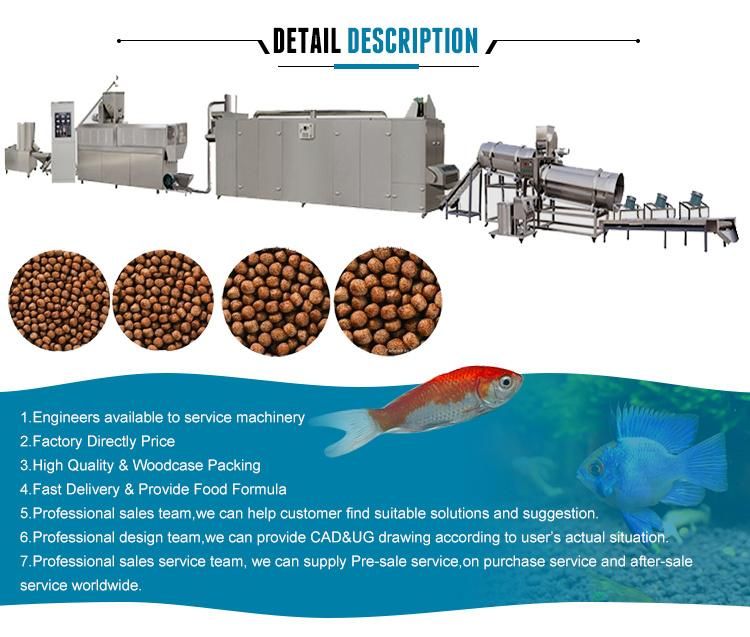

Small floating fish feed pellet making machine extruder Floating fish feed machinery

1.Product Application:

1. It is widely used for producing high-grade aquatic feed pellets for fish, catfish, shrimps, crab etc.

2. The final feed pellets have unique shape and good taste, high nutrition and smooth textures.

3. The pellets floating time on water surface can be adjusted by the extrusion degree.

4. Currently, floating fish feed exturder has become an ideal equipment for small and medium fish farm (catfish, tilapia, shrimp etc) holders or fish feed processing plant.

5.Floating Catfish Feed Production line| Product Name | Floating fish feed machinery |

| Material | stainless steel |

| Capacity | 140-160kg/h,240-260k/h,500-600kg/h,800-1000kg/h |

| Power | 75kw,100kw,150kw,180kw |

| Voltage | 380V/50HZ or as clients' local voltage |

| Dimension | 18m*2m*4m,22m*2m*4m,28m*2m*4m |

| type | Fully automatic,continuous and high speed |

| Application for | dog food,cat food,fish feed,shrimp feed,poultry feed |

2.Our machine produce fish feed sample show:

Different moulds make different pellets size.You can choose the suitable size you like.

For pet food, the moulds shape can be custom made.You can choose any moulds shape you like.

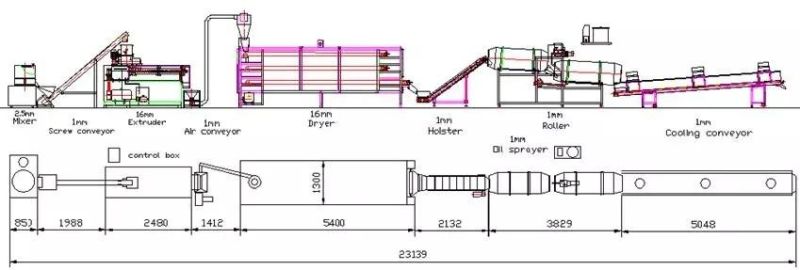

3.Flow chart of Floating fish feed machinery:

Mixer ⇒ Screw conveyor ⇒ Extruder ⇒ Air conveyor ⇒ Dryer ⇒ Flavor roller⇒Cooling Conveyor ⇒ Packing machine

4.Floating fish feed machinery Advantage :

1. Floating fish feed machinery can produce dry fish food for trout, salmon, grass carp, herring, carp, Tilapia, gurnard, etc.

2. Floating fish feed machinery can produce both Floating and Sinking Fish feed with high content of protein. The fish can get abundant nutrient and then grow fast, healthy and no waste of the fish food in the fish farm(pond);

3. These machines also can make dog food, cat food, wolf food, etc.

4. We will provide various formulations after the order;

5. Full free consult service forever.

5.Technical Parameter of Floating fish feed machinery

| Model | DT65 | DT70 | DT85 |

| Installed capacity | 76kw | 95kw | 178kw |

| Power | 54kw | 66kw | 125kw |

| Output | 140-160kg/h | 240-260kg/h | 500kg/h |

| Dimension | 17*2*2.5m | 22*2*2.5m | 26*2*3.5m |

7.SERVICE

Service for Pre-sale

1.Provide technical parameter2.Factory layout and size suggestion

3.Provide general formulation

4.Custom-Design service

5.Professional Advice about Market, machines, materials, packing

6. Suggesting professional ship agent or helping book ship as customer request.

7. 24 hours online service.

Service for After-sale

1.Allocation chart as the buyer's request will be supplied.2.Operation manual will be supplied after shipment.

3.One year warrantee, life time maintenance with cost price.

4.Free easy broken spare parts will be sent with container .

5.First installation can be done by engineer.

6.Training workers in customer's factory.