Factory Price Electric Industrial Drum Wood Chipper Shredder Machine

ZHENGZHOU SHULIY MACHINERY CO., LTD.- Type:Wood Chipper

- Power Source:Electric

- Certification:ISO9001

- Trademark:SL

- Origin:China

Base Info

Description

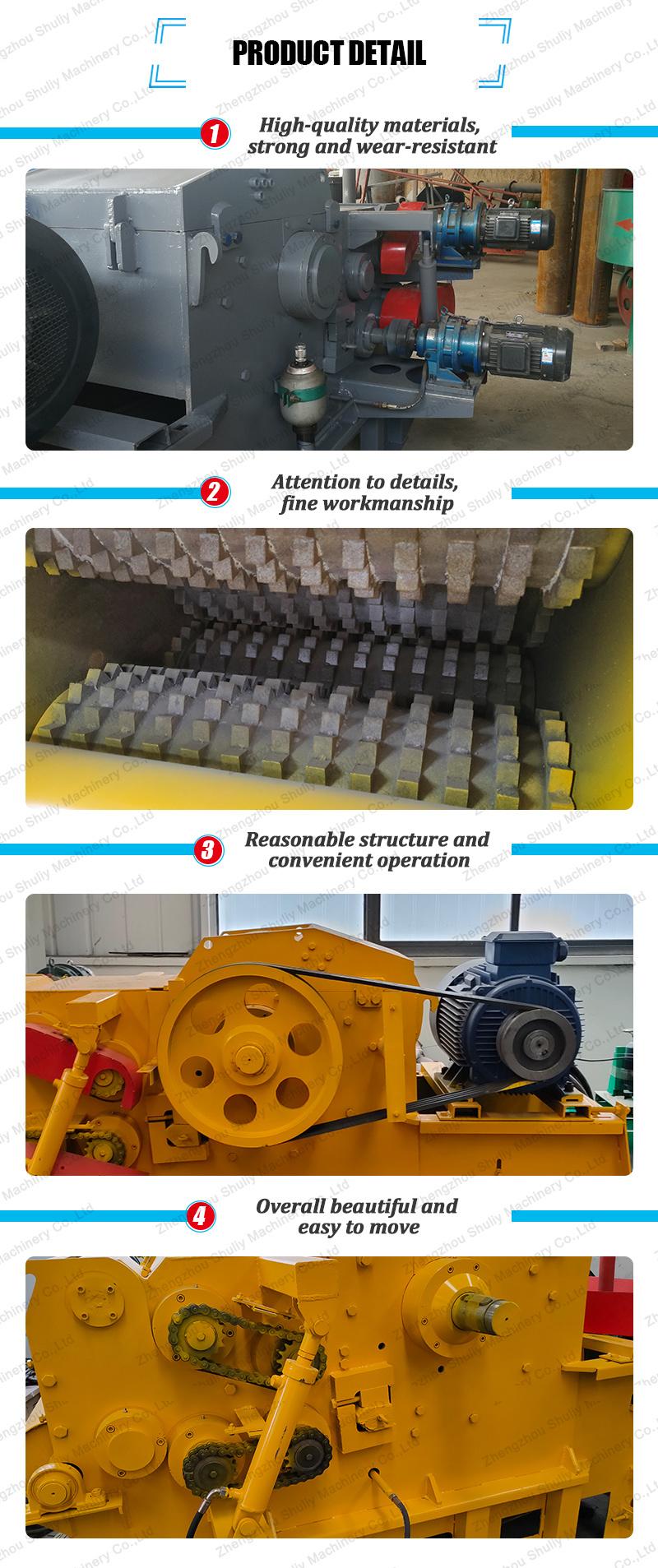

Structure and Working Principles of drum wood chipper:

It consists engine base, cutter roller, feeding roller, conveyor and hydraulic system and so on. The engine base is welded by high strength steel plate. On the cutter roller, there install two or three flying cutters. Through the professional bolt, fixed the flying cutters on the roller. According to the thickness of the raw materials, the feeding roller can move up and down through the helping of the hydraulic system. The satisfied chips can be discharged at the bottom of the machine through the screen. The bigger chips will be cut again in the chamber of the machine.

Features

1.Machine body: It is welded by a high-strength steel plate, which is the supporting foundation of the whole machine.

2.Knife roller: Two or three or four flying knives are installed on the knife stick, and the flying knife bolts are specially made to fix the flying knives on the knife roller through the pressure block.

3.Hydraulic system: The oil pump is supplied to the oil cylinder, and the cover can be activated to facilitate the replacement of the blade; the upper feeding roller assembly can be lifted during maintenance, which is convenient to adjust the gap between the flying knife and the bottom knife and the disassembly and assembly of the comb plate.

4. Up and down feeding mechanism: It is composed of a feeding interface, upper and lower feeding rollers and a feeding gap adjustment mechanism. The wood entering from the feeding interface is pressed by the upper and lower feeding rollers and is fed to the cutting mechanism at a certain speed. Control the size of the cut wood chips; when processing thick wood, it is adjusted by the feed gap adjustment mechanism.