Ring Die Wood Pellet Feed Pellet Making Machine (WSWH)

Zhengzhou Runxiang Machinery Equipment Co., Ltd.- Type:Pellet Mill

- Processing Object:Animal-Derived Feed

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:With Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

- Pellet Mill Type:Ring Die Pelleter

Base Info

- Model NO.:WSWH series

- Bulking Machine Type:Sigle Screw Bulking Machine

- Expanding Method:Wet Expansion

- Condition:New

- Applicable Materials Shape:Powder

- Capacity:20 Sets Per Month

- Machine Application:Any Kinds of Animals

- Material:Carton Steel

- Machine Capacity:0.2-2t H

- Diameter of Final Wood Pellet:3-8mm

- Transport Package:Export Wooden Cases

- Specification:ISO, CE, CO, CCC

- Trademark:GMEC

- Origin:Zhengzhou

- HS Code:8437800000

- Production Capacity:240 Sets Per Year

Description

Basic Info.

Model NO. WSWH series Bulking Machine Type Sigle Screw Bulking Machine Expanding Method Wet Expansion Condition New Applicable Materials Shape Powder Capacity 20 Sets Per Month Machine Application Any Kinds of Animals Material Carton Steel Machine Capacity 0.2-2tH Diameter of Final Wood Pellet 3-8mm Transport Package Export Wooden Cases Specification ISO, CE, CO, CCC Trademark GMEC Origin Zhengzhou HS Code 8437800000 Production Capacity 240 Sets Per YearProduct Description

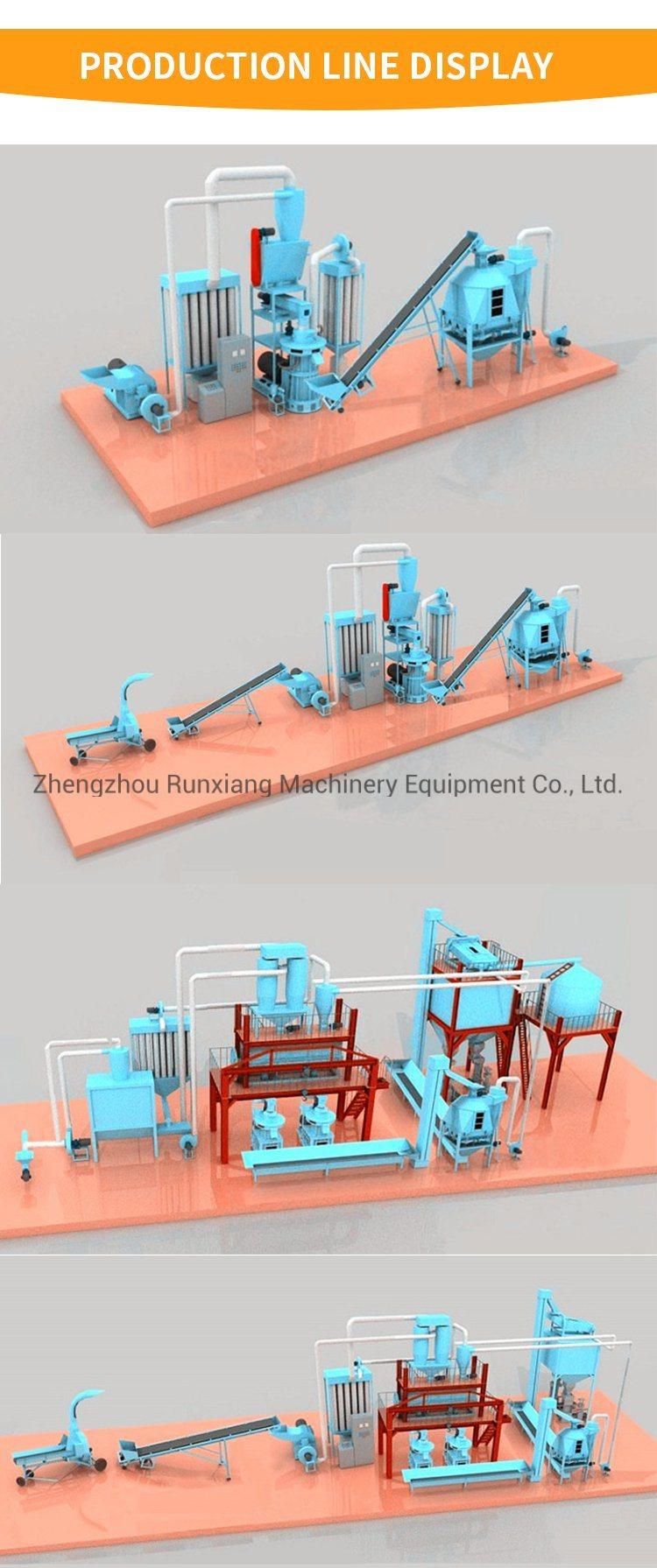

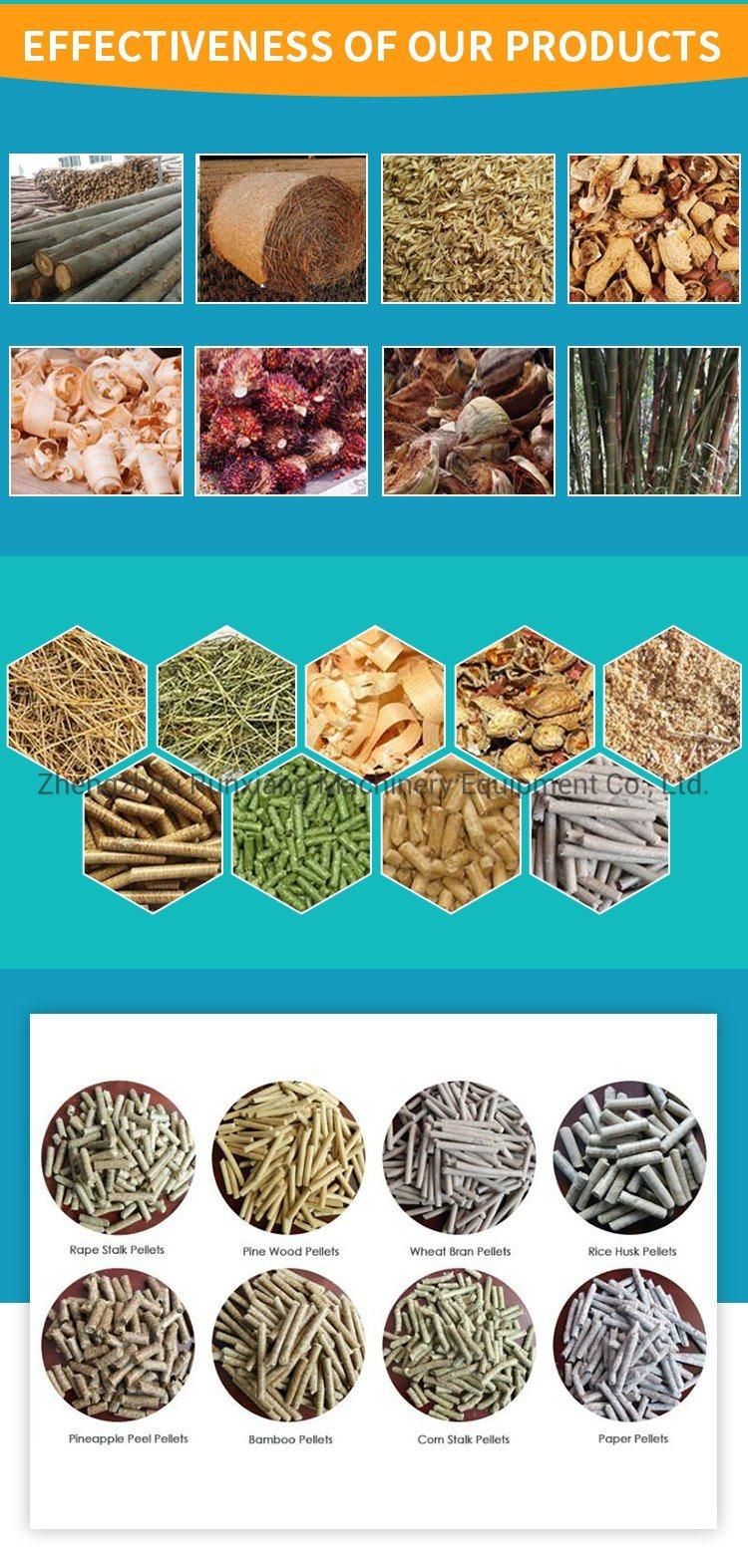

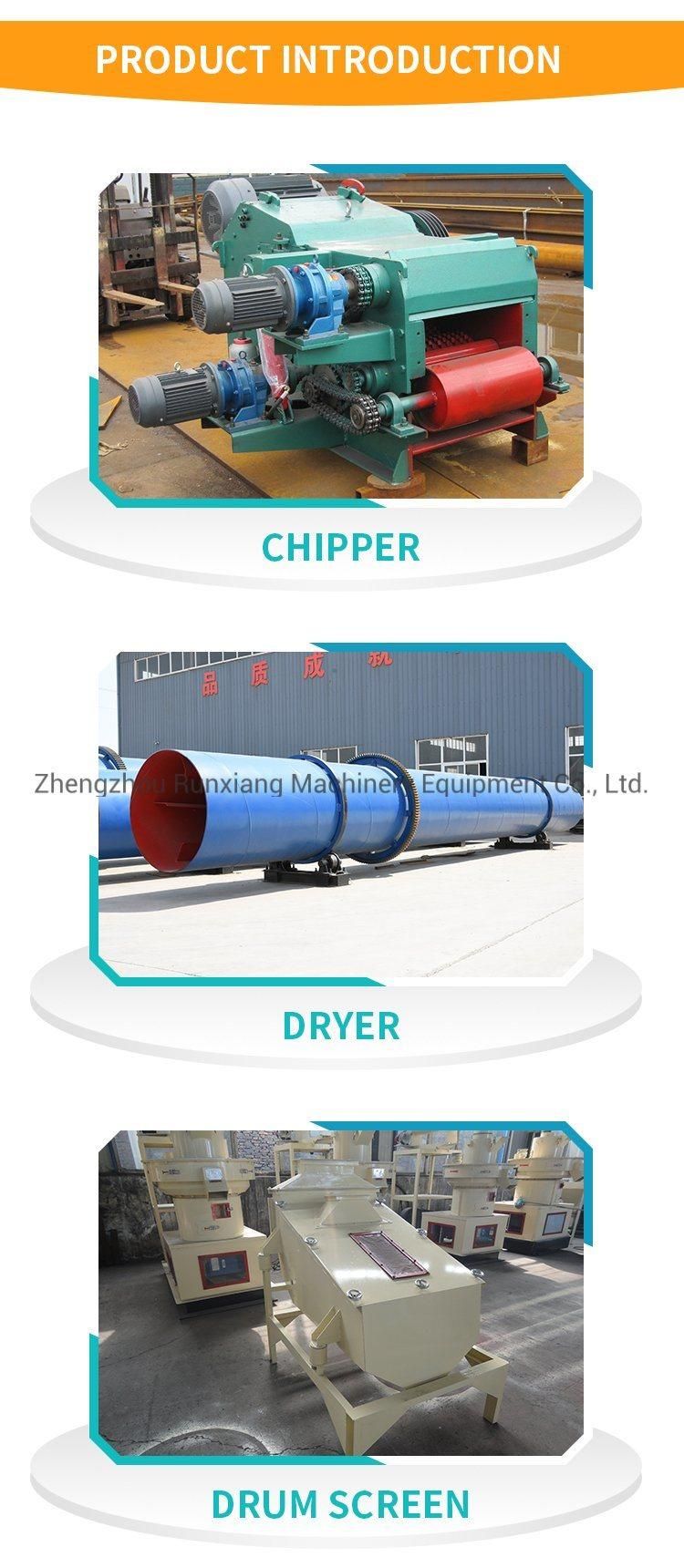

Wood or Feed Pellet Mill Press processing Machine line (WSWH)Our company have different kinds of pellet machine processing machine line. Home farm use small flat die pellet machine, big capacity ring die feed pellet factory use different models of pellet mill machine, you can choose any one you need, we will reply you at the first time when we get your inquiry.

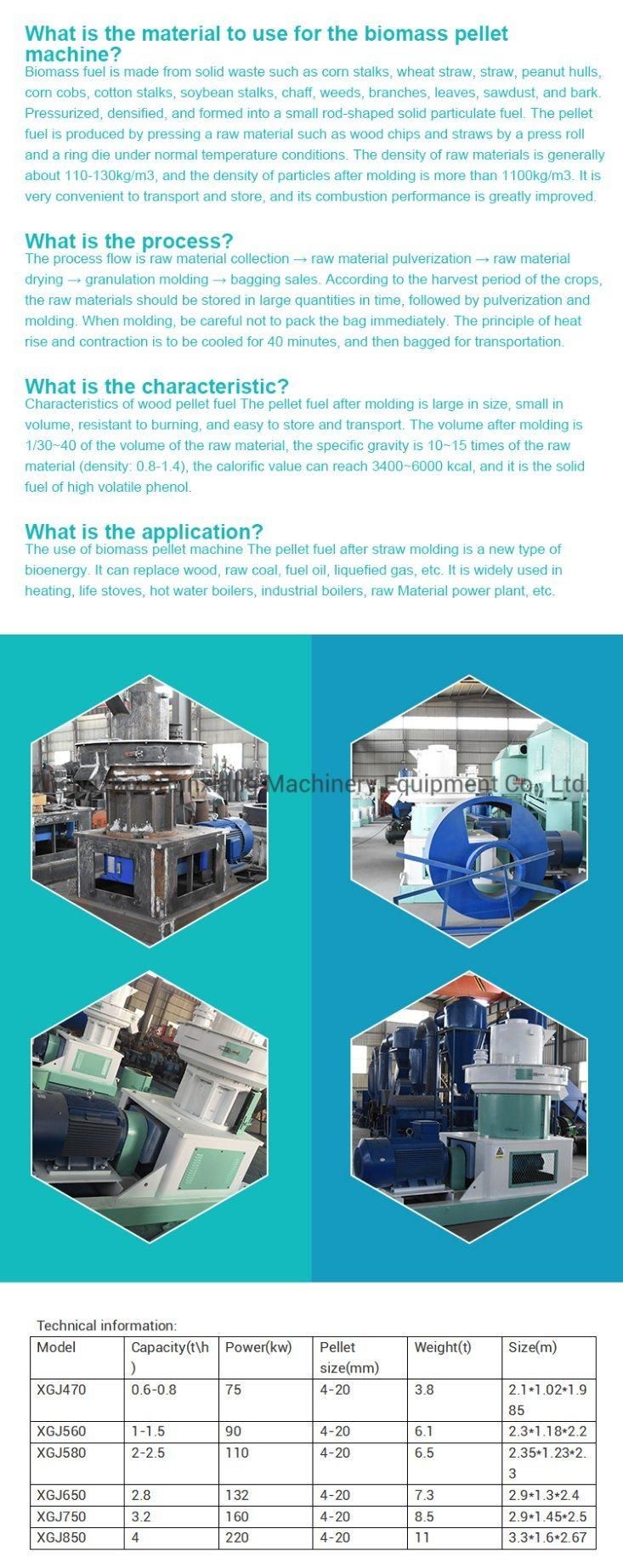

Advantages of Ring Die Pellet Mill:

1. Ring die pellet mills generate less wear and tear since both the inner and outer edges of the roller traverse the same distance.

2. Ring die pellet machines are more energy efficient than the flat die pellet mill. Roller slip during the pelleting process brings extra friction, but this extra friction is a good element in the production of qualified wood pellets due to the additional heat.

Main Features:

1. 98% energy transfers - meaning less energy wasted.

2. Adopting aerodynamics technology & the current round principle reduces the temperature in pelletizing chamber to around90° C. As a result the machine can work well continuously.

3. Timing feeder can control the feeding speed so as to lower the block ratio.

4. The body is more durable because of the ductile iron material.

5. Capacity increased after adding another force feeder made from stainless steel to increase the feeding spread area.

6. The key working part become stronger after modifying the material, and improving heating processing technology, etc.

These main parts are forging pieces. Now, the processing of our ring die can reach to 800-1000MT. Ring die is assembled by quick-discharge clip.

| Model | Capacity | Main motor power | Feeding motor power | Conditioner motor power | Diameter of ring die | Diameter of final wood pellet |

| WSWH-25 | 0.2-0.3t/h | 7.5*2kw | 0.75+0.55kw | 2.2kw | 250mm | 3-8mm |

| WSWH35 | 0.5-0.7t/h | 30*2kw | 0.75+0.55kw | 2.2kw | 350mm | 3-8mm |

| WSWH-42 | 1.0-1.5t/h | 55*2kw | 1.5+0.75kw | 5.5kw | 420mm | 3-8mm |

| WSWH-520 | 2.0t/h | 75*2kw | 1.5+0.75kw | 7.5kw | 520mm | 3-8mm |