Manufacturer Szlh320 2-4 T/H Livestock Feed Pellet Mill Machine

Jiangsu Liangyou Zhengda Co., Ltd.- After-sales Service:Engineer Available

- Type:Pellet Mill

- Processing Object:Beans

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:With Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

Base Info

- Model NO.:SZLH320

- Pellet Mill Type:Ring Die Pelleter

- Bulking Machine Type:Twin Screw Bulking Machine

- Expanding Method:Wet Expansion

- Condition:New

- Applicable Materials Shape:Granular

- Warranty:1 Year

- Output(T/H):2-4tph

- Inner Diameter:320mm

- Transport Package:Pallet

- Specification:CE, ISO, SGS

- Trademark:Liangyou

- Origin:China

- HS Code:8438800000

- Production Capacity:5-20tph

Description

Basic Info.

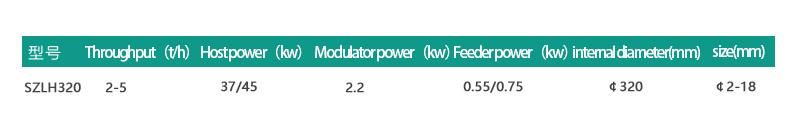

Model NO. SZLH320 Pellet Mill Type Ring Die Pelleter Bulking Machine Type Twin Screw Bulking Machine Expanding Method Wet Expansion Condition New Applicable Materials Shape Granular Warranty 1 Year Output(T/H) 2-4tph Inner Diameter 320mm Transport Package Pallet Specification CE, ISO, SGS Trademark Liangyou Origin China HS Code 8438800000 Production Capacity 5-20tphProduct Description

China Manufacturer Durable 2-4 t/h Livestock Feed Pellet Mill For Sale SZLH32

Feature Description:

1.This machine is with small occupy, low power consumption, low noisy and adjustable feeding. It also featured with compact structure, beautiful appearance and stable performance

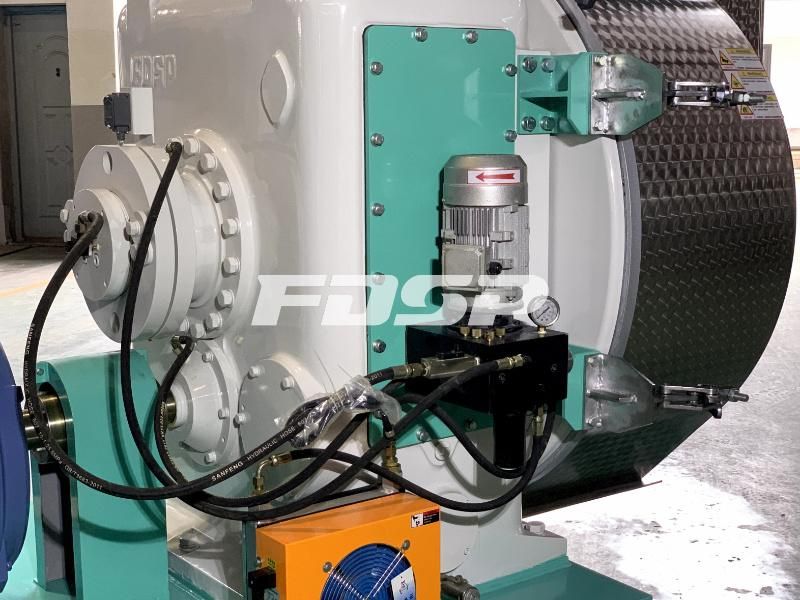

2. The main transmission casing is made by casting with large bearing, good stability, long service life.

3. Gear directly-connecting driving is adopted for high efficiency; the capacity could be 15% higher than belt pellet mill, High precision aircraft grade gear grinding process is adopted for ensure the stable and low noisy gear driving.

4.the feeding system of this machine is controlled by stepless variable frequency motor, and easy to adjust the speed.

5. Be equipped with shear pin which will broke if main motor overloaded to protection.

6. Be equipped with two cutter which can control the length of granule effectively

7. Full stainless steel feeder, conditioner and door cover will avoid the corrosion to pollute the raw material, with long service life

8. This machine has high output, low noise, low power consumption, long service life, easy to use and other features

9. Humanized design, careful for safety operation and use: the door cover is equipped with travel switch, the main motor will automatically power off to achieve active protection when the door cover opened, , in addition, the transmission parts are with closed shell.

10. the ring die are assembled with clamp type which is easy to change and reliable in driving

Notes for key feed processing equipment using

There are many kinds of feed processing equipment, among which the key equipment affecting feed granulation is nothing but hammer mill, mixer, granulator. In today's increasingly fierce competition, many manufacturers to purchase advanced production equipment, but because the operation of the use of error, often occur equipment failure. Therefore, feed factory's correct understanding of the use of equipment attention is not to be ignored.

Ring die pellet mill

Pelleting machine is the key equipment in the production process of each feed factory, also can be said to be the heart of the feed factory. The correct use of granulator directly affects the quality of granulated products.

Matters needing attention when using pellet mill:

1) In the production process, when there is too much material entering the granulator and the electric current rises suddenly, the manual discharging mechanism must be used to discharge the material out of the granulator.

2) When the door of granulator needs to be opened, the power supply must be cut off first. After the granulator stops running completely, the door can be opened.

3) When restarting the granulator, the ring die of the granulator must be turned one circle manually before the granulator can be started.

4) When the machine breaks down, the power supply must be cut off and the machine must be shut down for elimination. It is strictly forbidden to use hands, feet, wooden bars and iron to carry out rigid elimination in operation. It is strictly forbidden to start the motor by force.

5) when the new ring die is used for the first time, new roller should be also used, and the oil material mixed with fine sand (all pass through 40-20 mesh sieve, the ratio of material to oil and sand is about 6∶2∶1 or 6∶1∶1) can be used to wash the ring die for 10 to 20 minutes, then the ring mould can be put into normal production.

6) assist repairman to check and add oil to main motor bearing once a year

7)Assist the repairman to replace the lubricating oil 1-2 times a year for the granulator gearbox.

8) Tubular magnet must be cleaned at least 1 time per shift.

9) The steam pressure entering the conditioner jacket is not higher than 1 kgf/CM2.

10) The steam pressure entering the conditioner is in the range of 2-4 kgf/CM2(generally not less than 2.5 kgf/CM2 is suitable) .

11) Lubricate the rollers 2-3 times per shift.

12) Clean the feeder and conditioner 2-4 times a week (once a day in summer) .

13) The distance between the cutter and the ring die is generally not less than 3mm.

14) During normal production, the main motor current is strictly prohibited to exceed the rated current or overload operation.

FAQ

About FDSP

| Important year | Important events |

| 2003 | Predecessor of Jiangsu Liangyou - Liangyou Machinery Co., Ltd. is established near the beautiful Tianmu Lake in Liyang, Changzhou, a professional feed machinery manufacturing enterprise is founded. |

| 2004 | Liangyou(FDSP) established a sophisticated quality system standards, passed and obtained the ISO 9001: 2000 international quality system certification successfully. |

| 2006 | The enterprise was renamed Jiangsu Liangyou Agro Machinery Co., Ltd(FDSP). and gained SGS Certification, it is an important part of the full life cycle quality management system combined with the product quality and service quality, which is built by effort of Liangyou. |

| 2008 | Jiangsu Liangyou(FDSP) exported 10TPH fertilizer complete production line to Korea successfully. It becomes the Integrated solution solver who can independently design and undertake large fertilizer engineering in the domestic industry , Jiangsu Liangyou opened up the international market successfully |

| 2009 | Jiangsu Liangyou expanded by enlarging the land of 15000 square meters in Zhongguancun Science and Technology Industrial Park in Jiangsu.The new production base was born, which means the first take-off of Jiangsu Liangyou. |

| 2013 | Jiangsu Liangyou Company Diamond Jubilee: the tenth anniversary celebration of the company, the inauguration of new plant, the listing ceremony of agro and renewable energy machinery engineering institute. |

| 2014 | Jiangsu Liangyou International Mechanical Engineering Co., Ltd. was established in Nanjing. Liangyou developed the international market of feed machinery, fertilizer machinery, biomass pellet mill, silo project and other markets with brand new quality and service. |

| 2015 | Jiangsu Liangyou Group was estabilished, with one parent company and four subsidiary companies. expanded the plant once again, as high-tech enterprise, advanced science and technology enterprise, Jiangsu Liangyou has a rapid development, the second production base was founded by enlarging 25,000 square meters of land |

| 2017 | Jiangsu Liangyou zhengda co., LTD(FDSP) listed bell ceremony was held in Beijing.Phase ii officially start construction for the new site (on May 25, 2017, obtain the construction permit). |

| 2019 | FDSP phase ii new plant completed and put into production, which further promote the industrial upgrading, providing the possibility of further development in a wider field. |

| .... | More future |

1.Q:Are you a factory or trading company?

A:We are a manufacturing and trading company.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Liyang City, Jiangsu Province, China, near Shanghai.Our company is located in Nanjing City,Jiangsu Province,China.You can fly to Shanghai

airport directly.All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:How does your factory do regarding quality control?

A:"Quality is our soul. We always attach great importance to quality controlling from

the beginning to the end. We have many engineers to R&D our products.

4.why choose our products?

A:"Good products! Good reputation! Good service! Good price! "

If you have any question, please contact us freely. Our after-sales service team on-line will do the best to accomplish your sincere requirement on time.