High Quantity Chicken Feed Pellet Mill Line

Jiangsu Liangyou Zhengda Co., Ltd.- After-sales Service:Provided

- Type:Feed Set

- Processing Object:Animal-Derived Feed

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:With Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

Base Info

- Model NO.:SKJZ5800

- Pellet Mill Type:Ring Die Pelleter

- Bulking Machine Type:Twin Screw Bulking Machine

- Expanding Method:Wet Expansion

- Condition:New

- Applicable Materials Shape:Granular

- Warranty:1 Year

- Model Number:Skjz5800

- Power(W):172kw

- Voltage:380-440V

- Capacity:4-6 Tph

- Pelleted Feed Size:4-12mm

- Other Models:Skjz1800, Skjz3000, Skjz4800, Skjz3800

- Application:for Making Feed Pellets

- Transport Package:Iron Pallet and Soft Guard

- Specification:2000KG

- Trademark:FDSP

- Origin:China

- HS Code:84361000

- Production Capacity:10sets Per Year

Description

Basic Info.

Model NO. SKJZ5800 Pellet Mill Type Ring Die Pelleter Bulking Machine Type Twin Screw Bulking Machine Expanding Method Wet Expansion Condition New Applicable Materials Shape Granular Warranty 1 Year Model Number Skjz5800 Power(W) 172kw Voltage 380-440V Capacity 4-6 Tph Pelleted Feed Size 4-12mm Other Models Skjz1800, Skjz3000, Skjz4800, Skjz3800 Application for Making Feed Pellets Transport Package Iron Pallet and Soft Guard Specification 2000KG Trademark FDSP Origin China HS Code 84361000 Production Capacity 10sets Per YearProduct Description

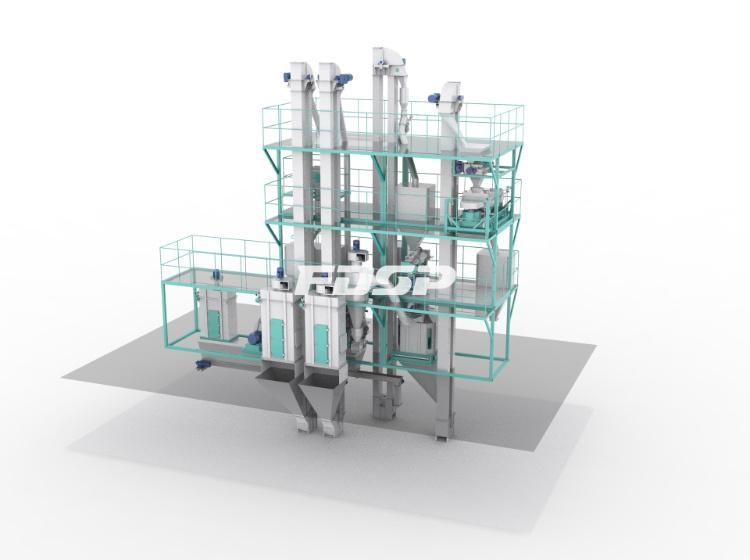

High Quantity Chicken Feed Pellet Mill LineBrief introduction for flow process:

SKJZ5800 Feed set adopts manual batching system with 5-6t/h output for mesh feed 4-5t/h output for pellet feed. The raw material should be weighed in advance before feeding into the production line through two different dumping hopper, in which the material need to be grinded should go into the hammer mill through granule inlet in batches, hammer mill use the pre-cleaner as the feeder, the material no need grinding will go into the production through powder inlet after weighed in advance, then mixed in mixer, the material after mixing can go into the FP bins directly to be mesh finished products. It can also go into the pelletizing process to be pelletized, cooled, finally packed by manual weighing.

The total power of the feed set is about 172Kw, dimension is : 13x6x11m, matching 0.5T boiler. The feed set use splicing type frame and is characterized by compact design and reasonable structure, and the satisfaction of environment protection requirements, meanwhile it can be directed to customers design.

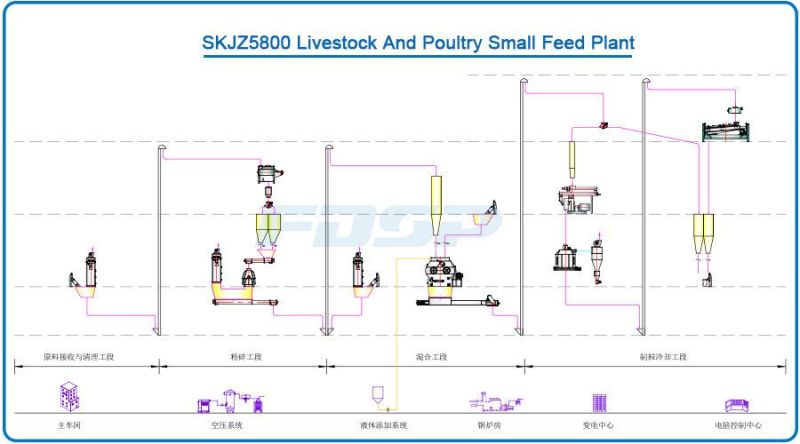

Technological process chart:

RM receiving and cleaning process--Grinding process--Mixing process--Pelletizing and cooling process --Auxiliary process

Technological characteristics and introductions:

RM receiving and cleaning process: granules and powder material will be put into the production line separately though two inlet, the granules will be screened and cleaned to remove impurities by pre-cleaner, then remove the iron before it go into the hammer mill, the powder material should be cleaned in advance.

Grinding process: adopts FDSP's tear circle hammer mill which can make both coarse grinding and fine grinding, the feeder is combined together with the pre-cleaner which can clean the material and also feeding into the hammer mill, variable frequency control, evenly feeding and equipped with pulse filter. Mechanical induct discharging. The process is simple and with low cost, it is suitable for small capacity and multi type of material's grinding.

Grinding machine: hammer mill SFSP568-II with power 37KW, output: 5-6t/h

Mixing process:there is pre-mixing bin upper the mixer which can make the feeding continuously when mixer working, the mixed material can go into the pre-pelleting bin and mesh feed bins separately to meet the requirement for producing mesh feed and pellet feed at same time.

Mixing equipment: double shaft paddle mixer SHSJ1 with 11kw, 500kg/P, homogeneity CV≤5%

Pelletizing process: adopt one pellet mill with single conditioner which is suitable for normal poultry feed and ruminant feed production. the material go into the cooler directly after pellet mill, then go into the crumbling and screening system through bucket elevator, manual packing at last.

Pelletizing equipment: pellet mill SZLH350 with 55kw, output:3-7t/h.( ¢3.5 normal broiler feed formula)

Cooling equipment: counter flow cooler SKLN2.5 with output 5-6t/h

Crumbler: SSLG15x100 with output 3-5t/h, it can crumble the large feed pellets into small pellets to produce small chicken grow seedling feed. the crumbler is designed with by pass system so the material can be go into the screener though by pass when no need to use crumbler.

Screening equipment: plan rotary screener SFJH80×2C with capacity 4-6t/h

Auxiliary system: liquid adding system could adding oil into the mixer to improve feed palatability. Air compressing system is used to supply compressed air for pneumatic components.

About Us:

FAQ:

1.Q:Are you a factory or trading company?

A:We are a manufacturing and trading company.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Liyang City, Jiangsu Province, China, near Shanghai.Our company is located in Nanjing City,Jiangsu Province,China.You can fly to Shanghai

airport directly.All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:How does your factory do regarding quality control?

A:"Quality is our soul. We always attach great importance to quality controlling from the beginning to the end. We have many engineers to R&D our products.

4.why choose our products?

A:Good products! Good reputation! Good service! Good price!