ISO9001 Certification Weed Cutting Dredger

Qingzhou Keda Environment Protection Machinery Co.,Ltd.- Type:Horizontal Cut Harvester

- Application:Straw

- Power Source:Diesel

- Harvest method:Cutting

- Drive Type:Gear Drive

- Transmission:Hard Shaft

Base Info

- Model NO.:KDGC

- Certification:ISO9001:2008

- Color:Customized

- Condition:New

- Aquatic Weed Cutting Machine Operation:One Man

- Aquatic Weed Cutting Machineworksite:River, Pool, Shallow Sea or Else

- Working Speed:3km,H

- Harvesting Width:2.6m

- Garbage Loading:3000m2,H

- Powder:75kw

- Usage:Aquatic Weed Harvester

- Transport Package:Container,in Bulk

- Specification:SGS,GPM,ISO

- Trademark:KEDA

- Origin:Shandong, China

- HS Code:8905200000

- Production Capacity:100sets,Year

Description

Basic Info.

Model NO. KDGC Certification ISO9001:2008 Color Customized Condition New Aquatic Weed Cutting Machine Operation One Man Aquatic Weed Cutting Machineworksite River, Pool, Shallow Sea or Else Working Speed 3km/H Harvesting Width 2.6m Garbage Loading 3000m2/H Powder 75kw Usage Aquatic Weed Harvester Transport Package Container/in Bulk Specification SGS/GPM/ISO Trademark KEDA Origin Shandong, China HS Code 8905200000 Production Capacity 100sets/YearProduct Description

ISO9001 Certification Weed Cutting Dredger

1. Weed Cutting Dredger Feature:1) Easy to dismantle, transport

2) We take up vegetation cleaning contracts also with our machineries.

3) Automatic aquatic weed harvester is custom designed as per customers' site conditions and requirements.

4) Painted five layers of anti-rust marine paint.

5) Our company can design by customers' requirement

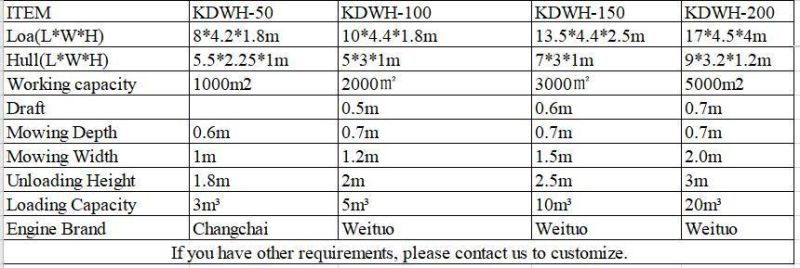

2. Weed Cutting Dredger Basic parameters

3. KEDA Produce Aquamarine designs and manufactures aquatic weed harvesters in a range of sizes to meet our customer's needs.

1) Due to collection belt and the storage belt, we enable fast loading and unloading; where by non-productive processing time is decreased.

2) The driver's cabin in our modern aquatic weed harvesters is located at the front of the boat so as to guarantee an optimal general view when mowing, as well as with unloading.

3) In order to be able to travel under the low bridges with the aquatic weed harvester, we have developed the innovative system of driver cabins that can be lowered during operation.

3-1. Weed Cutting Dredger Working Introduction

1) Aquamarine aquatic plant harvesters are hydraulically driven with reciprocating knives mounted on the harvesting head to cut the aquatic vegetation.

2) The vegetation is then transferred onto the conveyor system located on the closed deck barge.

3) The storage conveyors are gradually filled up with tightly packed plants and this harvested biomass is then transferred to the shoreline or into a dump truck via a shore conveyor.

3-2. We supply Weed Cutting Dredger to clean vegetations, wastes in lakes, canals, rivers etc 1) Aquatic Weed Cutting equipment is used for collecting floating trash,aquatic weed and doing salvage job in reservoirs, rivers, lakes and coastal water.2) Aquatic Weed Cutting equipments designed for easy operation, high efficiency, and stable performance. 3)All the collecting,conveying,draining,stocking and transporting movement can be completed by one man via controlling the buttons and switches on the control desk. 4) Aquatic Weed Cutting equipment work efficiency of the machine is thirty times as much as people cleaning4. Applications

5. About our company

1) Qingzhou Keda Mining Machine Co., Ltd. mainly produces iron selecting equipment, kinds of dredgers, dredging equipment, sand washing and sand making equipment, gold panning equipment, magnetic separating, and crusher and so on

2) We design produce several of products according to the customers requirement and geographical condition. It is a modern large-scale mineral processing equipment manufacturer for research and development, engineering design, producing installation, commissioning and after sale service.

3) Our company had established and improves the equipment file and service system, concentrating on customer feedback to make the products constantly improved to meet the customers' different needs.