Factory Directly Supply Micro Grinding Pulverizer Fine Particle Size

Jiangsu Liangyou Zhengda Co., Ltd.- After-sales Service:Engineer Available

- Type:Grinding Equipment

- Processing Object:Beans

- Screen Mesh:With Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

- Pellet Mill Type:Ring Die Pelleter

Base Info

- Model NO.:SWFL

- Bulking Machine Type:Twin Screw Bulking Machine

- Expanding Method:Wet Expansion

- Condition:New

- Applicable Materials Shape:Granular

- Warranty:1 Years

- Power(W):55-280kw

- Dimension(L*W*H):1350*1100*2500

- Motor Brand:Siemens

- Bearing Brand:Imported

- Application:Grinding Granular Materials

- Delivery Detail:30-45days

- After-Sales Service Provided:Engineers Available to Service Machinery Overseas

- Transport Package:Pallet

- Specification:CE, ISO9001, SGS

- Trademark:FDSP

- Origin:Jiangsu, China (Mainland)

- HS Code:8436990000

- Production Capacity:800-100h,400-500h

Description

Basic Info.

Model NO. SWFL Bulking Machine Type Twin Screw Bulking Machine Expanding Method Wet Expansion Condition New Applicable Materials Shape Granular Warranty 1 Years Power(W) 55-280kw Dimension(L*W*H) 1350*1100*2500 Motor Brand Siemens Bearing Brand Imported Application Grinding Granular Materials Delivery Detail 30-45days After-Sales Service Provided Engineers Available to Service Machinery Overseas Transport Package Pallet Specification CE, ISO9001, SGS Trademark FDSP Origin Jiangsu, China (Mainland) HS Code 8436990000 Production Capacity 800-100h/400-500hProduct Description

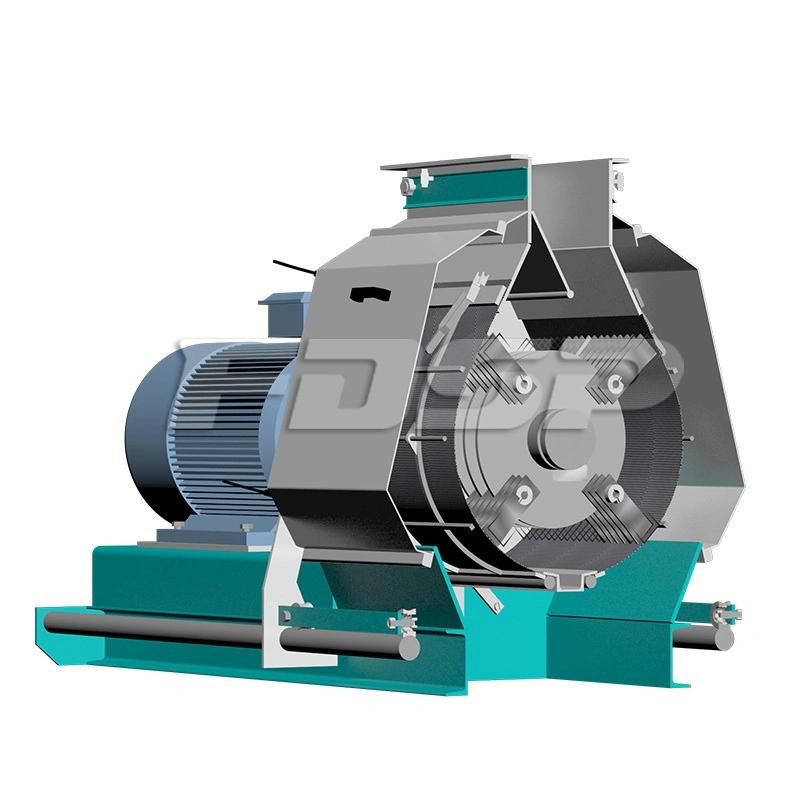

Factory Directly Supply Micro Grinding pulverizer Fine particle size getSWFL series vertical pulverizer is a kind of superfine pulverizing processing equipment. It is suitable for all kinds of large, medium and small feed mills. After primary screening, magnetic separation and mixing of various coarse materials such as corn, sorghum, rice, soybean meal, fish and shrimp ,the materials enter the pulverizer to achieve the required standard ultra-fine materials, especially suitable for ultra-fine pulverization of shrimp, turtle, carp and young animal feed.

Features:

Small vibration

The mesh structure enhances the overall strength and greatly reduces noise and vibration.

Low noise

A built-in dedicated muffler can greatly reduce noise and save space.

Efficient

The unique internal optimization structure of the machine improves the collision probability of materials and improves the hourly output. At the same time, the material selection is more precise and efficient, and the materials that are not easily crushed (such as soybean meal, bran, etc.) can also be effectively crushed;

Security

The hydraulic opening system reduces the labor intensity, easy maintenance, improves safety and shortens the maintenance period;

Weight removal and feeding system

Weight removal system, it can effectively remove 98% of raw material impurities (such as stones, iron, stainless steel, etc.). The feeding system feeds evenly and improves the generation of large currents during initial feeding.

Novel structure and stable performance

The machine adopts a non-screen structure, and the pulverization and grading are placed in the same confined space, so that the pulverization and grading are completed once, and the energy loss caused by over pulverization is reduced; the hammer design of the new structure has strong wear resistance and prolongs the use time, effectively reduce the cost of use; unique hammer mounting method, faster replacement of the hammer; unique arching device to prevent material arching during feeding.

Uniformly adjustable particle size

The pulverized particle size of 60-300 mesh is continuously adjustable, which can achieve ultra-fine pulverization with special requirements; use wind separation, transport, material temperature rise low.

Model parameter

| Model | SWFL110 | SWFL130 | SWFL150 |

| Ouput t/h | ≥4.0 | ≥5.0 | ≥7.0 |

| Main motor power kW | 110 | 132/160 | 200 |

Equipment allocation:

Shell material:carbon steel

Wearing plate material: alloy steel

Hammer knife material:Tungsten alloy cutter head

Bearing:imported

Hydraulic cylinder:custom-made

travel switch:Chint

Gear Reducer Motor: Zhejiang Donly/FDSP custom brand

Motor: Wannan / Siemens (China)

Notes for key feed processing equipment using

There are many kinds of feed processing equipment, among which the key equipment affecting feed granulation is nothing but hammer mill, mixer, granulator. In today's increasingly fierce competition, many manufacturers to purchase advanced production equipment, but because the operation of the use of error, often occur equipment failure. Therefore, feed factory's correct understanding of the use of equipment attention is not to be ignored.

Hammer mill

Hammer mill generally have two types: vertical and horizontal. The main components of the crusher are hammer and screen, hammer need durable wear-resisting and certain toughness, also need balanced arrangement so as not to cause vibration.

Notes for using hammer mill:

1) check the lubrication condition of the connecting parts and bearings before starting the machine, run the machine for 2-3 minutes, start feeding after normal operation, stop feeding after finish the production, and run the machine for 2-3 minutes, and then shut down the motor after all the material in the machine has been emptied.

2) Change the direction immediately when hammer abrasion reach the centerline. If all four corners are worn to the center, a new hammer piece is required. Note: The original arrangement should not be changed when changing, and the weight difference between each set of hammer pieces should not exceed 5G, otherwise it will affect the balance of the rotor.

3) The Air Net System of the hammer mill is very important to improve the efficiency of grinding and reduce the dust. Pulse filter with good performance should be chosed. After each shift, clean the inside and outside of the dust remover, remove the dust, check, clean and lubricate the bearing regularly.

4) The materials should not be mixed with iron, gravel and other sundries. If there is abnormal sound during production , should timely shutdown and make inspection, troubleshooting.

5) the working current and the feeding amount of the feeder at the upper end of the crusher should be adjusted at any time according to the different materials to prevent the jam and increase the crushing amount.