Professional Design Feed Production Line

Jiangsu Liangyou Zhengda Co., Ltd.- Type:Feed Set

- Processing Object:Animal-Derived Feed

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:With Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

- Pellet Mill Type:Ring Die Pelleter

Base Info

- Model NO.:SKJZ5800

- Bulking Machine Type:Twin Screw Bulking Machine

- Expanding Method:Wet Expansion

- Condition:New

- Applicable Materials Shape:Granular

- Warranty:1year

- Model Number:Skjz5800

- Voltage:380V 50Hz

- Power(W):191kw

- Dimension(L*W*H):10000mm*9000mm*13000mm

- Capacity:3-7tph

- Shaping Rate:97%

- Other Models:Skjz3000, Skjz3800, Skjz1800, Skjz4800

- Pelleted Feed Size:1.5-18mm

- Application:for Making Feed Pellets

- Transport Package:Iron Pallet and Soft Guard

- Specification:CE, ISO, SGS

- Trademark:FDSP

- Origin:China

- HS Code:84361000

- Production Capacity:50 Sets Per Year

Description

Feed Pellets Processing Technology

Raw Material Receiving→Grinding →Mixing →Pelletizing →Cooling →Crushing → Screening & Grading →Packing

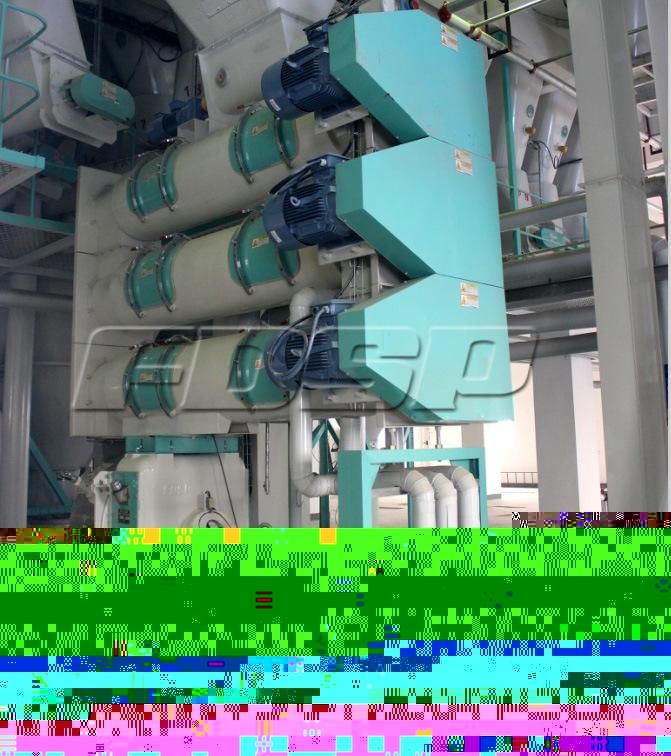

Equipment Related to Feed Pellet Production Line

Hammer Mill →Mixer →Pellet Mill →Cooler →Crumbler →Rotary Screener →Bagging Scale →Control Center

Detailed processes

1. Raw Materials Receving

We use independent dust collecting system for the raw materials inlet, and ensure

the working environment clean.

2. Grinding Process

The feed grinder can grind the raw material ingredients to the required size. There are various hammer mills which can satisfy different requirements.

3. Mixing Process:

Mixing is considered to be one of the essential operations in feed pellet processing. Lack of proper mixing may lead to reduced diet uniformity, affecting the feed pellet quality.

4. Pelletizing Process:

Feed pellet mill is the core equipment of the whole production line. According to different raw material, material formula and working condition, we can offer you different pellet mills.

5. Cooling Process:

The feed pellets pressed out by the feed pellet mill are hot and moist. They can't be crushed, screened or packed immediately. Counter-flow feed pellet cooler is designed to cool or dry the feed pellets. It can decrease the temperature and moisture of the feed pellets, preparing for the following processes.

6. Crushing Process:

Different poultry, livestock or aquatic feed pellets are with different sizes. Some big ones should be crushed into small ones. Roll type feed pellet crumbler is just the equipment for feed pellet crushing. Double-roll feed pellet crumbler is suitable for crushing poultry feed, such as chicken feed, duck feed and goose feed etc. Three-roll feed pellet crumbler is suitable to crush aquatic feed including fish feed and shrimp feed etc.

7. Screening, Grading and Packing Process:

The rotary grading sieve can be used to screen and grade the feed pellets. After processing, you can get the qualified feed pellets without fine powder.

Packing Process

The feed pellets should be packed for transporting, storing or selling.

8. Automatic PLC Control System:

With the automatic PLC control system, the production line is with high efficiency and convenient operation.

About Us

Jiangsu Liangyou International Mechanical Engineering Co., Ltd is affiliated to Jiangsu Liangyou Agro Machinery Co., Ltd which has about 20 years of experience in the comprehensive development and utilization in agriculture field. It covers an area of 15000 square meters, locating in the zhongguancun science &technology industrial park in Liyang City, JiangSu Province, PRC.

FDSP has sold Feed machinery and fertilizer machinery throughout China and exported to Korea, South Africa, Russia, Thailand, Taiwan, Philippines, Malaysia, Australia, Egypt, Syria, Nigeria, Ethiopia, India, Bangladesh, Pakistan, Iran etc.

Our Service:

Warranty:1 year

Our professional service includes: Free training, Guidance Installation and Debugging.

If you have any question, please contact us freely. Our after-sales service team on-line will do the best to accomplish your sincere requirement on time.

Certifications:

FDSP has obtained ISO9001:2008 international quality system certification, CE certification for feed machinery, fertilizer machinery, biomass equipment and complete sets of production line

Any interest in our product, please feel free to contact us at any time.