Rapeseeds Combined Automatic Pretreatment Cleaning Machinery

HUBEI FOTMA MACHINERY CO., LTD.- Structure:Vertical

- Press Series:First

- Voltage:380V

- Type:New-Type Hydraulic Oil Press

- Appearance:Vertical

- Press Materials:Oil Palm Fruit

Base Info

- Model NO.:TQLZ

- Condition:New

- Customized:Non-Customized

- Application:Oybean, Peanut, Sunflowers

- Model:Tqlz

- Transport Package:in Wooden Case

- Specification:EEC, SGS, OECD

- Trademark:FOTMA

- Origin:China

- HS Code:5911400000

- Production Capacity:2000 Sets,Year

Description

Basic Info.

Model NO. TQLZ Condition New Customized Non-Customized Application Oybean, Peanut, Sunflowers Model Tqlz Transport Package in Wooden Case Specification EEC, SGS, OECD Trademark FOTMA Origin China HS Code 5911400000 Production Capacity 2000 Sets/YearProduct Description

Rapeseeds Combined Automatic Pretreatment Cleaning MachineryThe oilseed in the harvest, in the process of transportation and storage will be mixed with some impurities, so the oilseed import production workshop after the need for further clean-up, the impurity content dropped to within the scope of technical requirements, to ensure that the process effect of oil production and product quality.

The impurities contained in oil seeds can be divided into three types: organic impurities, inorganic impurities and oil impurities. Inorganic impurities are mainly dust, sediment, stones, metal, etc., organic impurities are stems and leaves, hull, humilis, hemp, grain and so on, oil impurities are mainly pests and diseases, imperfect granules, heterogeneous oilseeds and so on.

We are careless to choose the oil seeds, the impurities within it may harm the oil press equipment in cleaning and separating process. Sand among the seeds may block the machine hardware. Chaff or huller left in the seed absorbs oil and prevents it from being expelled by the oilseed cleaning equipment. Also, stones in the seeds may do damage to screws of the oil mill machine. FOTMA has designed professional oilseed cleaner and separators to hazard these accidents while producing quality products. A efficient vibrating screen is installed to sieve the worst impurities. A suction-style specific grabity destoner was set up to remove stones and mud.

Of course, vibrating sieve is one of the essential equipment for oilseed cleaning. It is a screening device for the reciprocating motion of the screen surface. It has high cleaning efficiency, reliable work, so it is widely used to clean the raw material in flour mills, feed production, rice plant, oil plants, chemical plants and other industries classification system. It is a common cleaning machine that widely used in the oilseed processing plant, too.

1. Main structure and working principle for vibrating sieve

The oil seeds cleaning vibration sieve mainly consists of the frame, feeding box, sieve boday, vibration motor, discharging box and other components(dust suction, etc.). The honest material nozzle of the gravity table-board has two layers of semi-sieve and can remove part of the big impurities and small impurities. It is suitable for various grains warehousing storage, seeds companies, farms, grain and oil processing and purchase departments.

The principle of oilseeds cleaning sieve is to use the screening method to separate according to the granularity of the material. Materials are fed from the feed tube into the feed hopper. Adjusting plate is used to regulate the flow of materials and make them evenly falls in the dripping plate. With the vibration of screen body, materials flow to the sieve along the dripping plate. Large impurities along the upper layer screen surface flow into the miscellaneous outlet and discharged outside of the machine from the sieve underflow of the upper sieve to the lower sieve plate. Small impurities would fall to the baseboard of the machine body through the sieve hole of the lower sieve plate and discharged through small miscellaneous outlet. Pure materials flow into the net export directly along the lower screen surface.

In cleaners and separators, FOTMA also put in place a dust-cleaning system to make sure a clean work environment.

2.More Details for vibration sieve

1. The amplitude of oilseeds cleaning sieve is 3.5~5mm, the vibration frequency is 15.8Hz, vibrating direction angle is 0°~45°.

2. When cleaning, the upper sieve plate should be equipped with Φ6,Φ7,Φ8,Φ9,Φ10 sieve mesh.

3. In the preliminary cleaning, the upper sieve plate should be equipped with Φ12,Φ13,Φ14,Φ16,Φ18 sieve mesh.

4. When cleaning other materials, the oilseeds cleaning sieve with appropriate processing capacity and mesh size should be used according to the bulk density (or weight), suspension velocity, surface shape and material size

3. The characteristics of oil seeds cleaning

1. The process is designed according to the characters of the oilseeds targeted and will be more thorough cleaning;

2. To reduce the wear and tear on the follow-up equipment, reduce the dust at workshop;

3. To pay attention to energy saving and environment protection, reduce emission, save cost.

4. Photos

5. Packing and Shipping:

(1) Packing: Usually in the wooden cases for main machines and carton boxes for small parts.

(2) Delivery:

Usually in 5-45 days after payment, it depends on the model and order quantity. For small packages, we can choose delivery by air(Normal air or courier: DHL, TNT, UPS, FedEx, etc.). For large machines, we can arrange to ship by water( LCL or FCL, bulk cargo or RO/RO), train or truck.

6.Our Factory

7. Certificates

8. Customer Visiting

9. Installation site:

10.Why choose FOTMA?1.For more than a decade, with its excellent production technology and high-quality after-sales service, it has always been recognized and loved by users.2.Obtained many official promotion appraisals and won many national patents. The technology is continuously updated, the products are mature and reliable, and the technology always leads. 3.High oil output, clean and pure oil, good market efficiency. Original automation, intelligent technology, automatic electronic temperature control function, energy saving and high efficiency. 4.Original automation, intelligent technology, automatic electronic temperature control function, energy saving and high efficiency.5.FOTMA can provide a full set of technical support and perfect after-sales service, which is the first choice of urban and rural oil mills and small and medium-sized refineries.

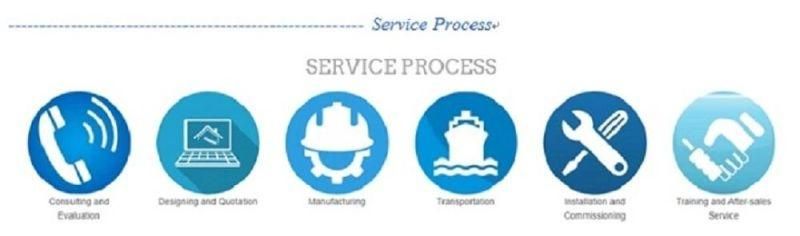

11. Our Service:

---One year quality warranty for the machine and spare parts

--- Oversea engineers service for installation

--- Whole-life after-sales service and free consultation

---Customized requirements available

---Technician guide at the site.

---24Hr online service

12. FAQ

Q1:- What's your advantage? Why we choose you?

A:- 1. Above 20 years' experience of designing, manufacturing and exporting of the grain and oil processing machinery. We have the most professional techniques and team and more advantage in price.

2. Over than 15-Years' Alibaba Gold Member. "Integrity, Quality, Commitment, Innovation" is our values.

Q2:- Can we mix different models and accessories together?

A:- You may mix different products or models in a single container but we would need to advise you on optimum loading and final capacity of your shipment.

Q3:- How do I visit you and the factory?

A:- You are welcomed to visit us and our factory at your convenience. We can pick you up at airport or train station and bring you to our factory . Let us know your schedule in details so we can arrange everything for you. Normally you need 3 days for an adequate visit to our factory.

Q4:- How can I become a dealer in my area?

A:- If you are qualified, you may apply for a dealership. We choose reliable partners for a long term business cooperation.

Q5:- Can I get an exclusive right for your machines in some territories?

A:- It depends on which country you are in. We have exclusive agents at several countries at this time. Most countries you can sell freely.

Q6:- After payment, how long will it take to get the machines we order?

A:- Normally 30-90 days after your payment (15-45 days for manufacturing, 15 - 45 days for delivery and shipment on sea)

13. Contact us

Ms. Danni Feng

Hubei FOTMA Machinery Co., Ltd

Add: No. 52 Guanggu Avenue, New High-tech Development Zone, Wuhan city, Hubei Province, P. R. China.

Web: fotmaricemill.en.made-in-china.com

Tel: +86 27 67848665, +86 18202720898