Small Feed Plant / Pellet Production Line for Cow

Jiangsu Liangyou Zhengda Co., Ltd.- After-sales Service:Provided

- Type:Pellet Mill

- Processing Object:Cereals

- Processing Technics:Crushing-before-Mixing

- Screen Mesh:With Screen Mesh

- Grinding Equipment Type:Feed Hammer Mill

Base Info

- Model NO.:Customize

- Pellet Mill Type:Ring Die Pelleter

- Bulking Machine Type:Sigle Screw Bulking Machine

- Expanding Method:Dry Expansion

- Condition:New

- Applicable Materials Shape:Granular

- Warranty:1 Year

- Output:20-30t,H

- Application:for Making Pellet and Mash Feed

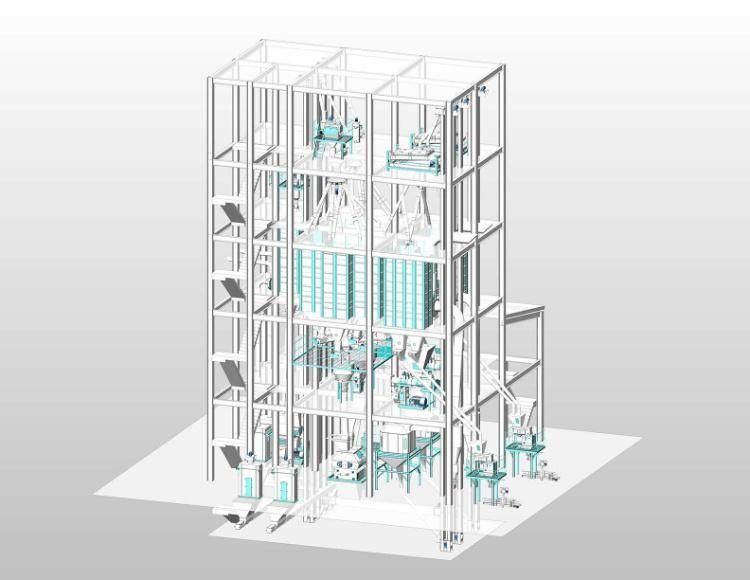

- Size:21*17.5*28m

- Cleaning:Crushing-Mixing-Pelletizing-Cooling-Sieving

- Feed:for Livestock, Poultry Fee

- Power:700kw

- Transport Package:Pallet

- Specification:2000KG

- Trademark:FDSP

- Origin:Jiangsu China

- HS Code:8438800000

- Production Capacity:50 Sets Per Year

Description

Basic Info.

Model NO. Customize Pellet Mill Type Ring Die Pelleter Bulking Machine Type Sigle Screw Bulking Machine Expanding Method Dry Expansion Condition New Applicable Materials Shape Granular Warranty 1 Year Output 20-30t/H Application for Making Pellet and Mash Feed Size 21*17.5*28m Cleaning Crushing-Mixing-Pelletizing-Cooling-Sieving Feed for Livestock, Poultry Fee Power 700kw Transport Package Pallet Specification 2000KG Trademark FDSP Origin Jiangsu China HS Code 8438800000 Production Capacity 50 Sets Per YearProduct Description

Small Feed Plant / Pellet Production Line For CowJiangsu Liangyou Zhengda Co., Ltd., specializing in the production of feed machinery and engineering, can provide customers with complete sets of equipment solutions for livestock feed (pig, etc.), poultry feed (chicken, duck, goose,etc.), ruminant feed (cattle, sheep, etc.), common aquatic feed (four major Chinese carps, etc.), special aquatic feed (shrimp, crab, etc.), extruded aquatic feed (floating and sink fish feed, shrimp feed, etc.), premix feed (including all kinds of additives, etc.), and pet food(cat food, dog food, etc.). to meet the different needs of customers.

Now take the Dual-line SZLH420(20tph) Ruminant feed production line as a case, according to the process flow and each section to do the following introduction and description.

Raw material:

The raw material of ruminant feed includes grains such as corn, wheat, barley, soybean meal(similar as poultry feed) , it also includes crude fiber such as green grass, hay, straw.

Introduction of process:

The features of ruminant feed are coarse grinding fineness(screen hole diameter 4-8mm),low curing and conditioning requirements(pellet mill adopts single layers conditioner),finished products with big pellet diameter(pellet diameter is around 4-10mm). Double sets SZLH420 ruminant feed process is with 20-30tph capacity, it adopts two grinding line, one batching & mixing line, two pelleting line and two packing line.

The total equipment power is around 700kw. The construction area of the production area is about 21*17.5*28m and equipped with 2T boiler. The whole line is compact in design, reasonable in structure, meeting the requirement of environmental protection, and can be customized designed according to the requirements of customers.

Process diagram:

Raw material receiving and cleaning process--Grinding process--Batching and mixing process-Pelleting process--Bagging or bulk process--Auxiliary process

Process introduction:

Raw materials receiving and cleaning section:

In this section, pellet feeding cleaning and powder feeding cleaning are separated independently and separate dust removal. Dust removal effect is good.

Cleaning equipment:granules sifter SCY80,capacity 20-30T/H;powder cleaner SQLZ60X50X100, capacity 10-15T/H.

Grinding section:

Because ruminant feed grinding fineness requirements are very thick,this section adopts two small power hammer mills, and each sets allocated with two pre-grinding bins, which can grind different materials at the same time and improve the efficiency. Before entering the bins, the impurities are removed by magnetic separation device to ensure the safe operation of the hammer mill.

Grinding equipment(2sets): Hammer mill SFSP668×800, 90kw, designed to produce 10-15t /h/set

Batching and mixing section:

This section adopts 16 batching bins. Two sets of batching system work at the same time. It is developed by our company to realize accurate fast and slow feeding, fast batching and high precision.

Weighing equipment: Dosing scale PCS20/PCS10, dosing precision: dynamic ≤3‰, static ≤1‰.

Mixing equipment: mixer SHSJ4, (30KW, 2000kg/ batch), designed to produce 20-30t /h. Mixture uniformity CV ≤5%.

Pelletizing section:

This section adopts two sets of single-layer pelletizer, and each set with two pre-pelleting bins, which is convenient to switch between varieties. After pelleting, they are respectively entered into the cooler and the elevator into the rotary screener in order to be screened, and the finished products are put into the packing bins. The sieved out powder material back to granulation, sieved out large particle material back to crumbler.

Pelleting equipment(2sets) : SZLH420, 110KW, designed to produce 8-15t/h/set(Ruminant feed pellet is large).

Cooling equipment(2sets) : SKLN6, 1.1kw, 6m3 volume, designed to produce 10-15t/h/set.

Packing section:

There are 4 finished product bins in this section, 3 bins of them are specially used to store pellet feed; There is also one bin for powder material and pellet material. The powder material finished products bins are designed special anti - grading device. The pellet or powder is automatically weighed and packed by the packing scale.

Packing equipment: Belt scale (it can be used as powder feed or granule feed), packing range: 20-50kg/ bag, 6-8 bags/minute.

Auxiliary section:

Dust removal system to improve workers' working environment; Grease adding system, common mixer place added to improve feed palatability.

FAQ:

1.Q:Are you a factory or trading company?

A:We are a manufacturing and trading company.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Liyang City, Jiangsu Province, China, near Shanghai.Our company is located in Nanjing City,Jiangsu Province,China.You can fly to Shanghai

airport directly.All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:How does your factory do regarding quality control?

A:"Quality is our soul. We always attach great importance to quality controlling from the beginning to the end. We have many engineers to R&D our products.

4.why choose our products?

A:Good products! Good reputation! Good service! Good price!